Magnetic assembly and method for defining a magnetic field for an imaging volume

a magnetic field and imaging volume technology, applied in the field of magnetic fields, can solve the problems of limited effectiveness, especially detrimental distortion, and geometric distortion in the resulting image, and achieve the effects of reducing the perturbation of patient dosimetry, reducing the size, and reducing the inhomogeneity of axisymmetric and/or non-axisymmetric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

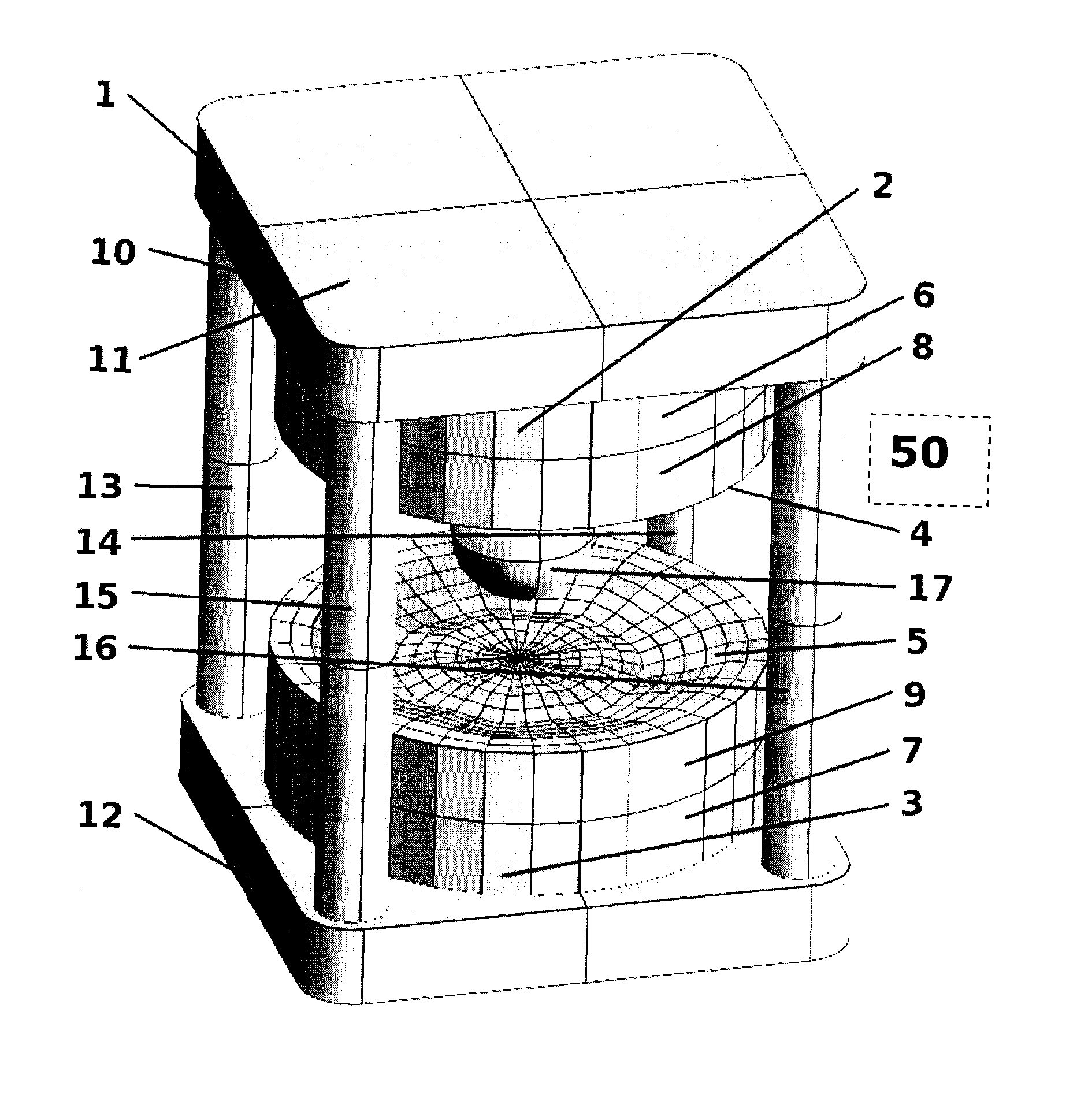

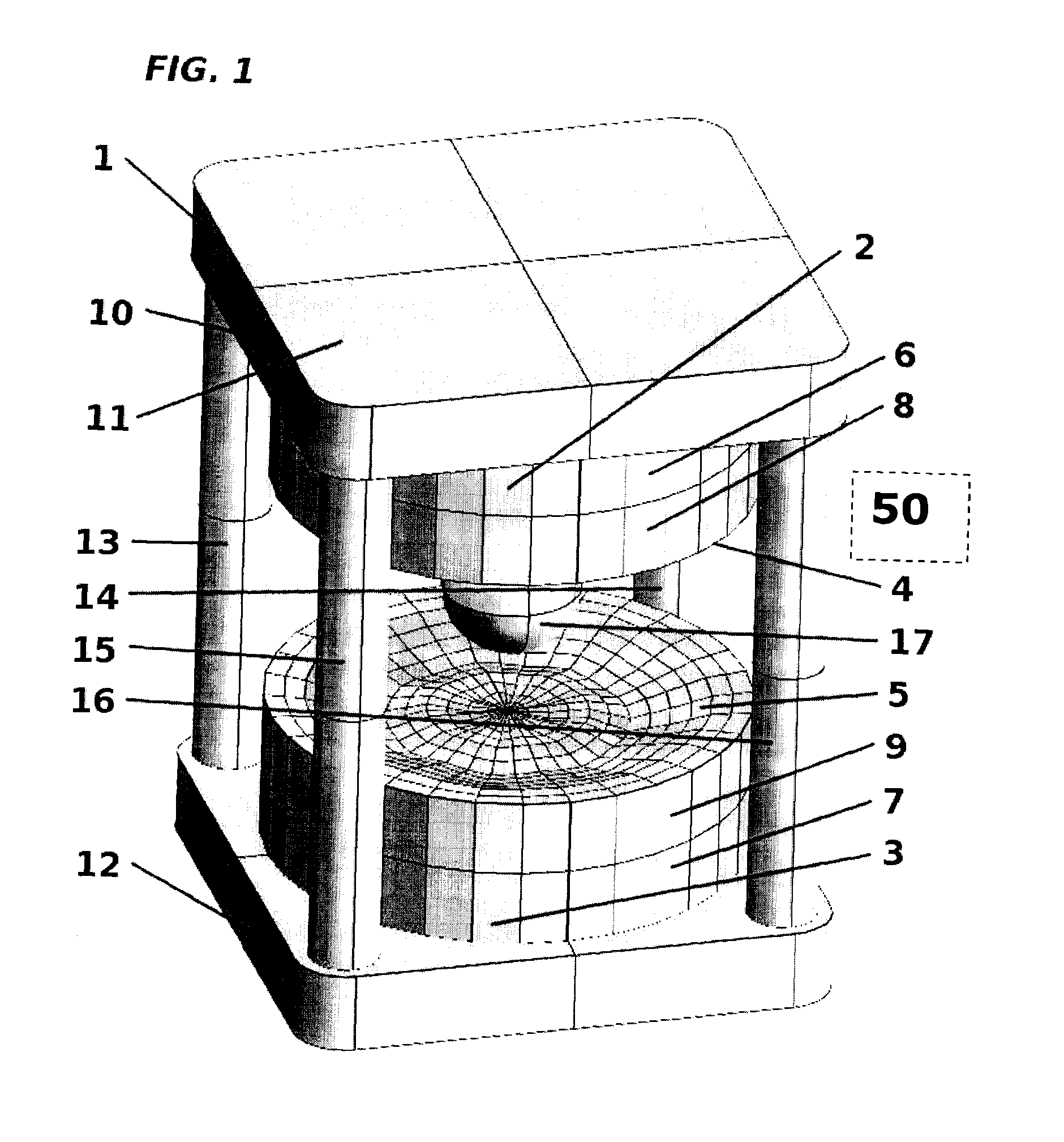

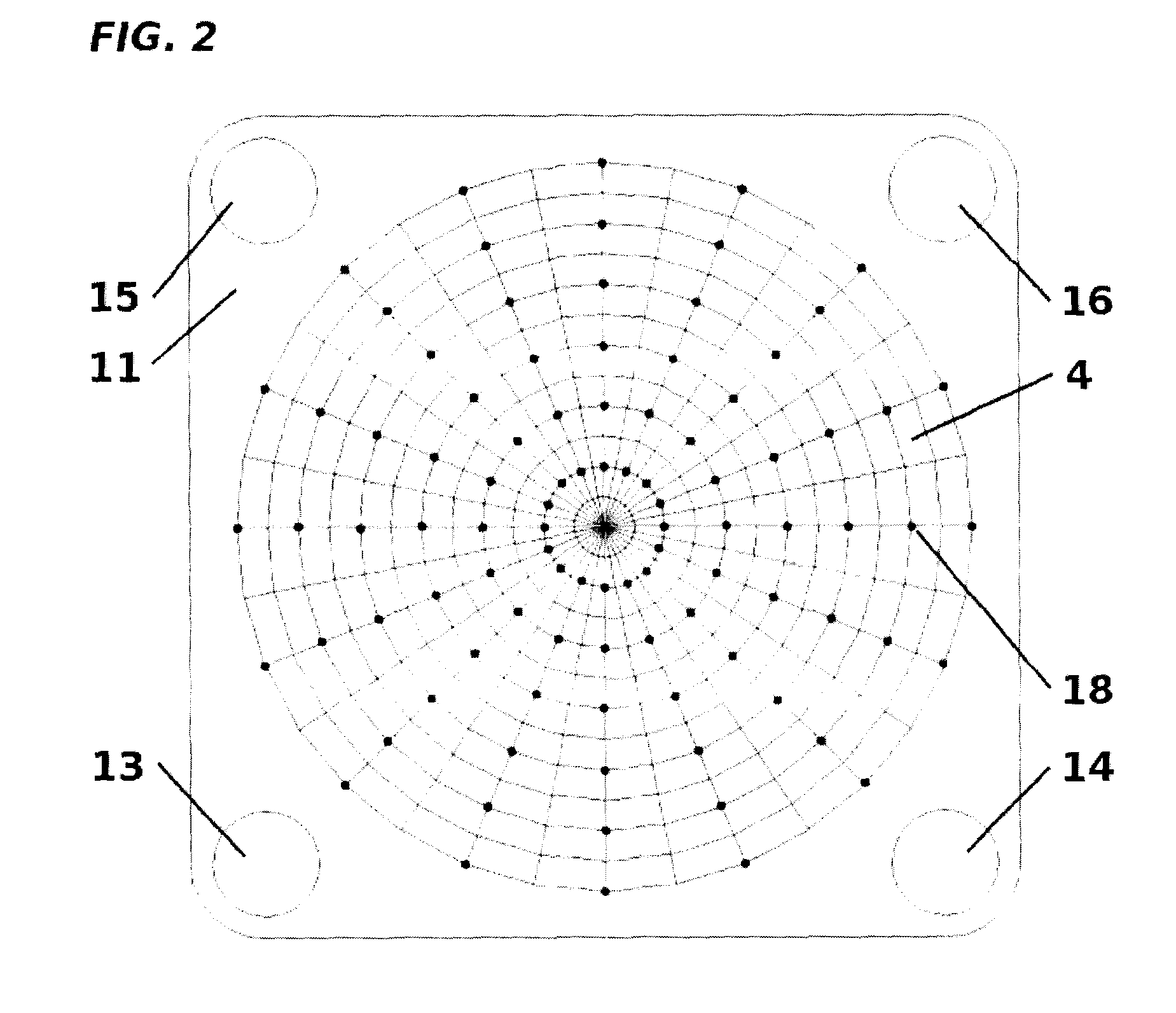

[0053]Referring now to the drawings wherein like numerals indicate like elements throughout, FIGS. 1-4 show a magnet assembly 1 according to an embodiment. In this embodiment, magnet assembly 1 includes a first ferromagnetic pole assembly 2 and a second ferromagnetic pole assembly 3. The first and second ferromagnetic pole assemblies 2, 3 are arranged in a fixed, spaced relationship with one another as “biplanar” magnets thereby to define a space therebetween that encompasses an imaging volume 17 and is large enough to receive an object (not shown) to be imaged at the imaging volume 17. The magnet assembly 1 is “open” as the object to be imaged can be moved between the pole assemblies 2, 3 to be positioned at the imaging volume 17.

[0054]In this embodiment, each of the first and second pole assemblies 2, 3 comprises both a cylindrical permanent magnet piece 6 (7) and a substantially cylindrical ferromagnetic piece 8 (9). The permanent magnet piece 6 (7) and substantially cylindrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| static magnetic field | aaaaa | aaaaa |

| magnetic field strengths | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com