Metalworking fluid compositions and preparation thereof

a technology of metalworking fluid and composition, applied in the field of metalworking composition, can solve the problems of affecting the effect of lubricant composition, affecting the effect of lubricating effect, so as to reduce the formation of mis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0086]Unless specified otherwise, the compositions are prepared by mixing the components in the amounts indicated in the Examples / Tables. The components used in the Examples are listed below.

[0087]EP agent is a commercially available sulfurized polymerized ester, 10% inactive sulphur extreme-pressure agent.

[0088]HYNAP™ N100HTS hydrotreated, naphthenic oil (Group V) is from San Joaquin Refining Oil, Inc. of Bakersfield, Calif.

[0089]Ashland™ 100SN Group 1 oil is from Ashland Inc.

[0090]Chevron™ 100R group 2 oil, Chevron™ 100R group 3 oil, and Chevron Synfluid 4 cSt PAO oil are all from Chevron Corporation of San Ramon, Calif.

[0091]Additive 2 is a sulfurized vegetable fatty acid ester. Defoamer is an acrylate oligomer antifoam / defoamer. Additive CAS is a commercially available overbased calcium sulphonate PEP metalworking additive containing carbonated alkylbenzene sulfonate. Additive SO is a sulfurized olefin.

[0092]Mineral seal oil (MSO) having a viscosity of 3.39 mm2 / sec at 40° C., an...

examples 1-6

[0095]A number of metalworking fluid compositions having components as listed in Table 1 were formulated and their properties were measured using various standard test methods: ASTM D1401-02 for Water Separability of Petroleum Oils and Synthetic Fluids; ASTM D 3427 (2003) Standard Test Method for Air Release Properties of Petroleum Oils; and ASTM D892-95 Foam Stability Sequence Test. As shown in the table, the example incorporating the isomerized base oil shows low foaming tendency (foam height of nil) and air release property that is comparable if not better than the prior art oil (in view of the test repeatability of 1 min.).

TABLE 1Example 1Example 2Example 3Example 4Example 5Example 6Group VGroup 1Group 2Group 3PAOGTLwt %wt %wt %wt %wt %wt %Sample IDSJR Hynap N100HTS - Group V95—————Ashland 100 SN - Group 1—95————Chevron 100 R - Group 2——95———Chevron UCBO 4R - Group 3———95——Chevron Synfluid, 4 cSt - PAO————95—GTL GST0449 isomerized base oil—————95EP agent555555Kinematic Viscosity...

examples 7-13

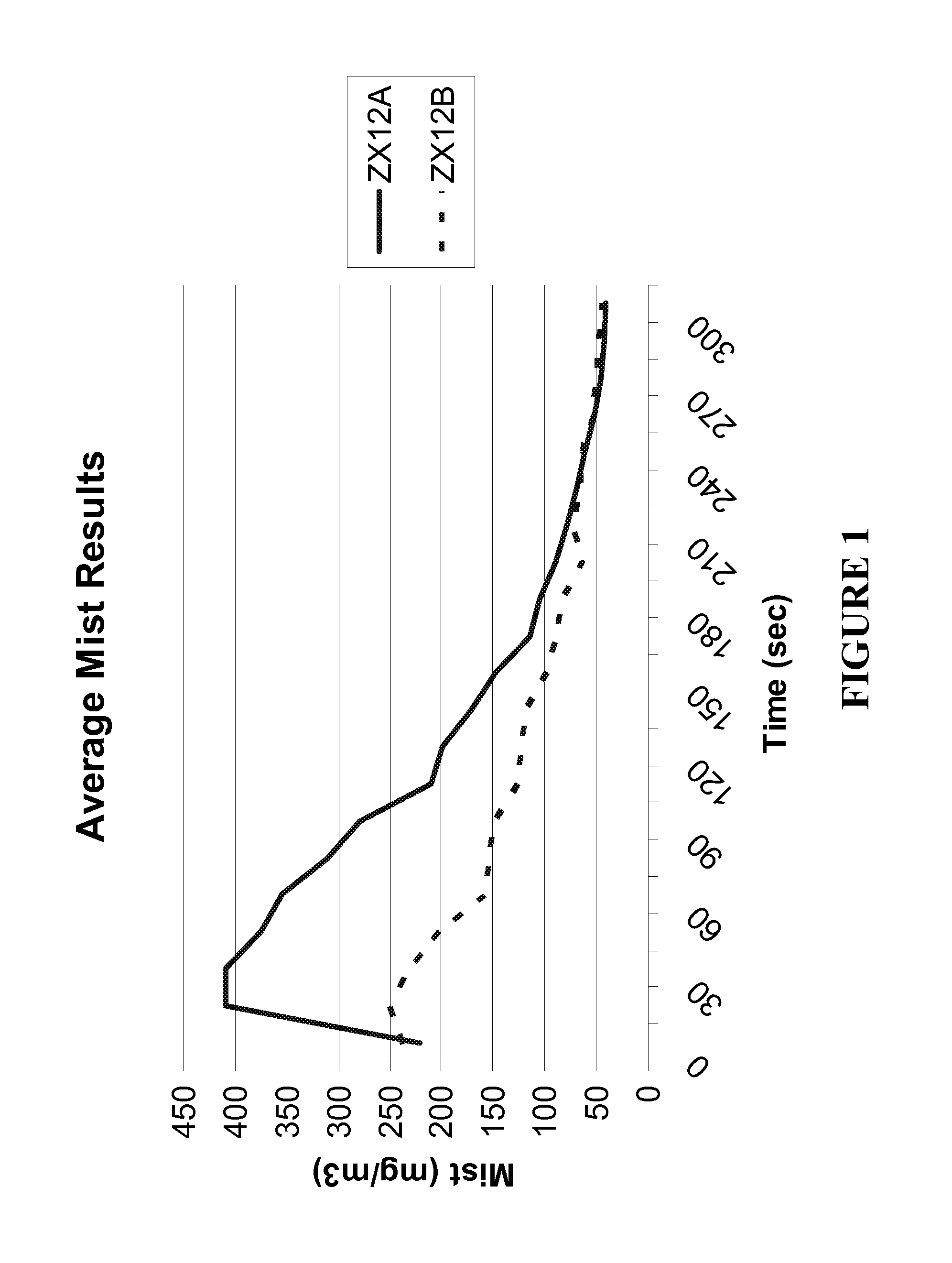

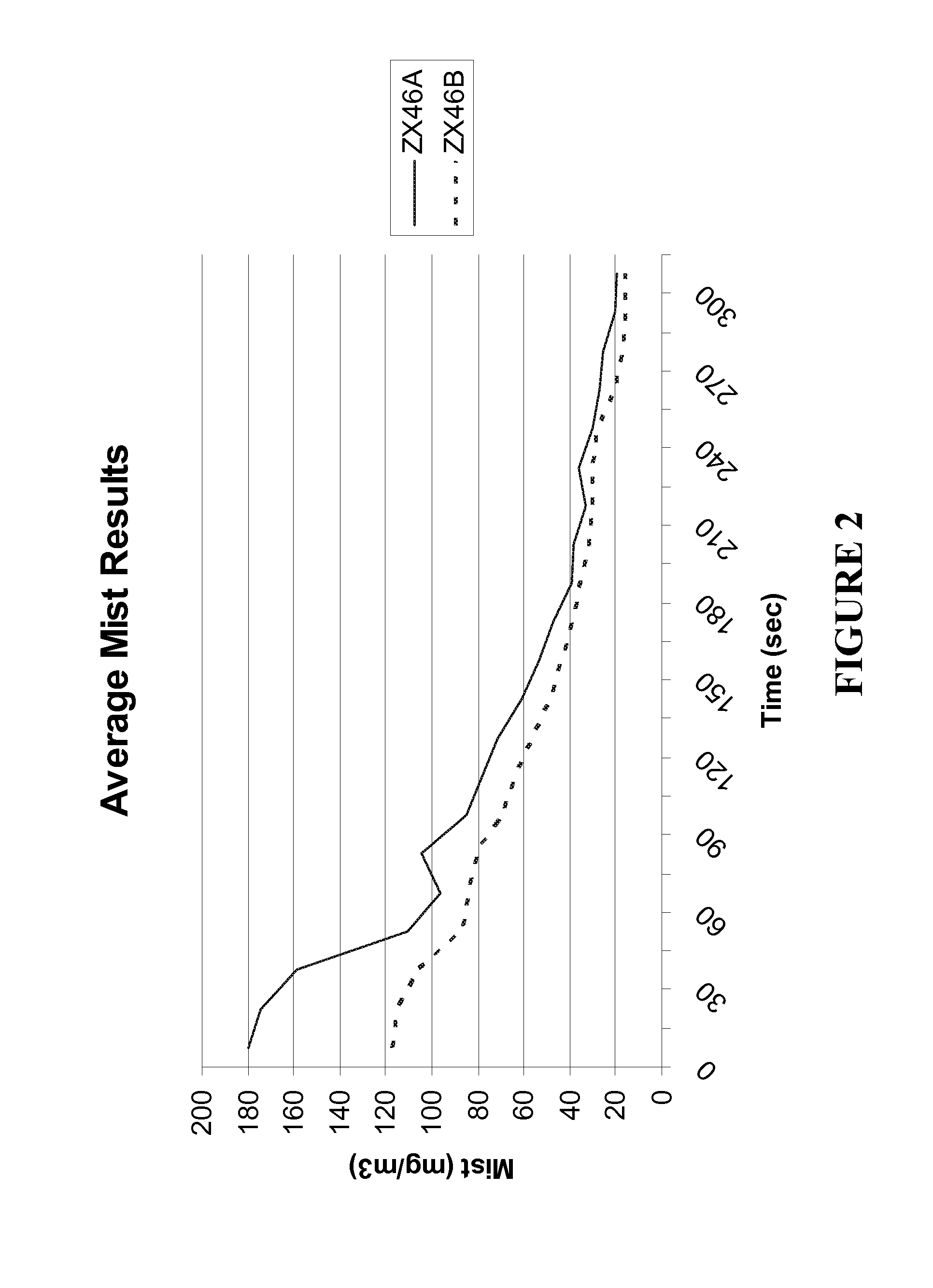

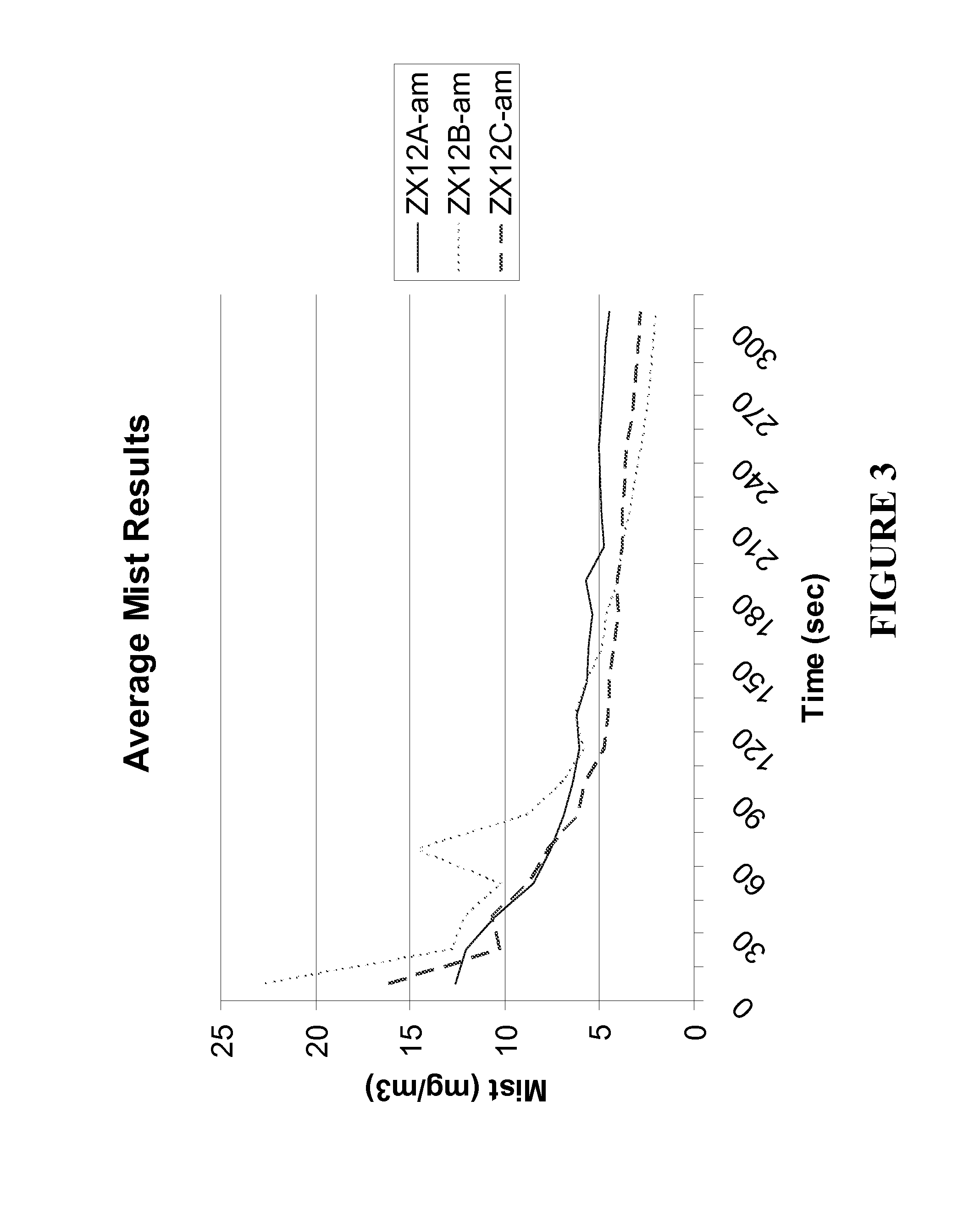

[0096]A number of metalworking fluid compositions having components as listed in Table 2 were formulated and their properties were measured / recorded. Examples 11-13 compare the compositions each with 0.25 wt. % of an anti-mist agent added (a high molecular weight oil soluble polymer tackifier).

[0097]The samples were subject to an aerosol (mist) formation experiment similar to the one described in “Polymer Additives as Mist Suppressants in Metal Cutting Fluids,” by Marano et al., Journal of the Society of Tribologists and Lubrication Engineers, October 1995, pp. 25-35. Basically in the test, metalworking fluid (in 100 mil. sample) was supplied to a coaxial atomizer's tip through a tube (e.g., ID of 0.0011 m) by a syringe pump at constant flow rates up to 0.0084 litre / min. Compressed air was supplied through the annulus between the outer and inner tubes (ID 0.0021 m and OD 0.0013 m, respectively) at flow rates up to 35 litres / min. Mist generated by the atomizer was directed to a long ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com