Biodegradable implant and method for manufacturing same

a biodegradable and implant technology, applied in bone implants, prostheses, coatings, etc., can solve the problems of difficult processing, disadvantages of metal implants, and easy breakage of ceramic implants, so as to reduce the young's modulus, increase the bone formation rate, and control the biodegradation rate. the effect of very low ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

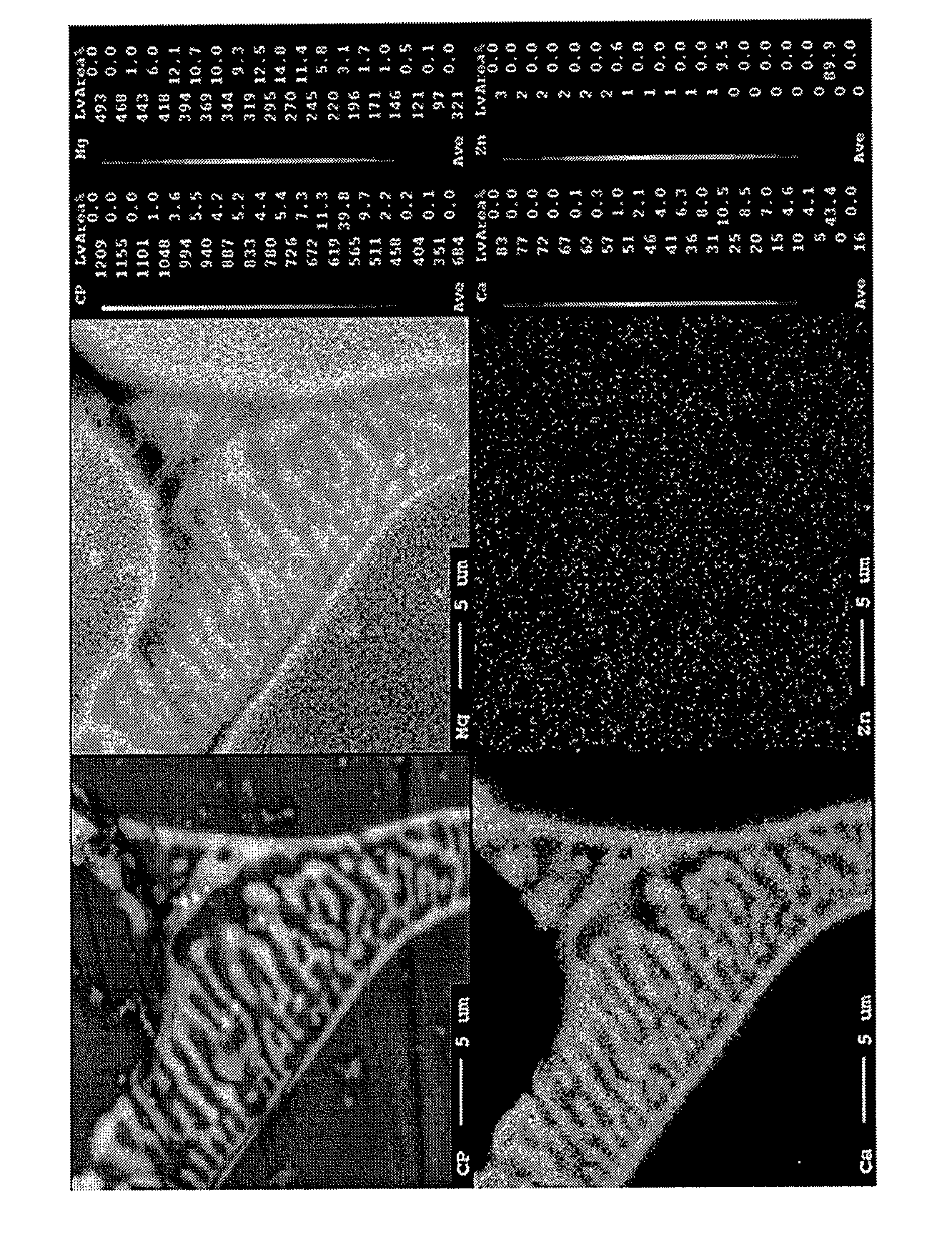

Image

Examples

examples 12 to 14

Manufacturing of Biodegradable Implant

[0157]Mg and Mn in the amounts shown in Table 7 below were charged in a crucible having an inner diameter of 50 mm that was made of stainless steel (SUS 410). Subsequently, while Ar gas was allowed to flow around the crucible so that Mg and Mn in the crucible did not come into contact with air, the temperature of the crucible was increased to about 700˜750° C. inside a resistance heating furnace, so that the Mg and Mn melted. The crucible was stirred so that the molten Mg and Mn were well mixed. The completely molten Mg alloy was cooled, thus preparing an Mg alloy in the solid phase. Also upon cooling, the crucible was immersed in water to enhance the mechanical strength of Mg, whereby the molten Mg alloy was rapidly cooled, resulting in a biodegradable implant

TABLE 7Mg (wt %)Mn (wt %)Ex. 12Remainder0.0015Ex. 13Remainder0.097Ex. 14Remainder0.51Mg: purity 99.98% Mg, MP21-31-31 (available from TIMMINCO)

example 15

Manufacturing of Biodegradable Implant

[0166]Mg and MgO in the amounts shown in Table 8 below were charged in a crucible having an inner diameter of 50 mm made of stainless steel (SUS 410). Subsequently, while Ar gas was allowed to flow around the crucible so that Mg and MgO in the crucible did not come into contact with air, the temperature of the crucible was increased to about 700˜750° C. inside a resistance heating furnace, so that the Mg and MgO melted. The crucible was stirred so that the molten Mg and MgO were well mixed. The completely molten Mg alloy was cooled, thus preparing an Mg alloy in the solid phase. Also upon cooling, the crucible was immersed in water to enhance the mechanical strength of Mg, whereby the molten Mg alloy was rapidly cooled, resulting in a biodegradable implant

TABLE 8Mg (wt %)MgO (wt %)Ex. 15Remainder10Mg: purity 99.98% Mg, MP21-31-31 (available from TIMMINCO)

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com