Mixed fiber spunbonded nonwoven fabric, and method for production and use thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

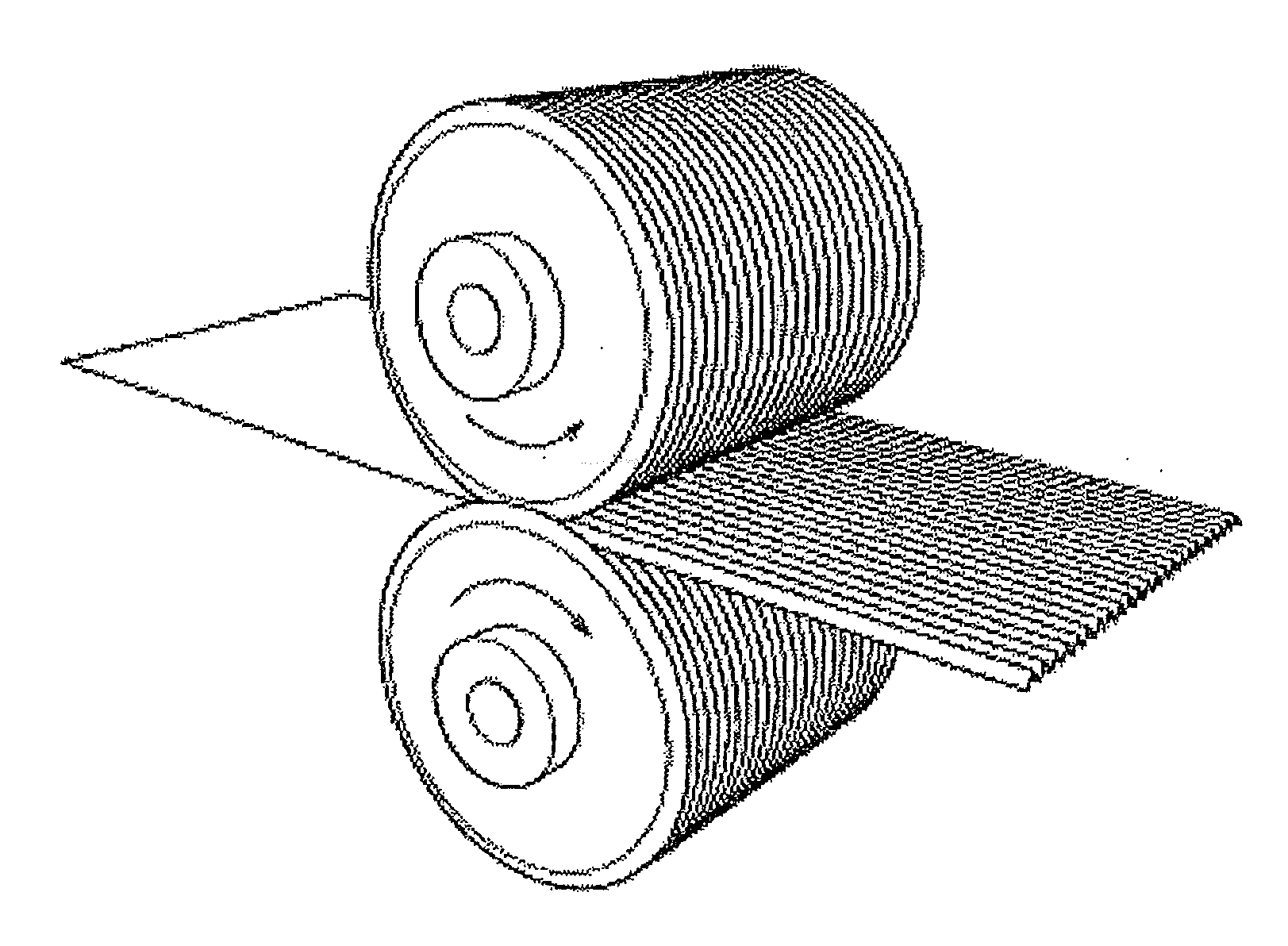

Image

Examples

example 1

[0150]Into 60% by weight of an ethylene oxide adduct of eicosanol [CH3(CH2)19—O—(CH2CH2O)2.5—H] and 40% by weight of a propylene homopolymer having a MFR of 30 g / 10 min, 0.05 part by weight of antioxidant (manufactured by Ciba, product name: Irgafos 168) was added. The mixture was melt-kneaded at 230° C., and extruded, thereby preparing a pelletized masterbatch (hydrophilizing agent AE-1).

[0151]96% by weight of a propylene homopolymer having a MFR, as determined in accordance with ASTM D 1238, at 230° C. under a load of 2.16 Kg, of 60 g / 10 min, a density of 0.91 g / cm3, a melting point of 160° C. (hereinafter referred to “PP-1”) was mixed with 4% by weight of a high density polyethylene having a MFR, as determined in accordance with ASTM D 1238, at 190° C. under a load of 2.16 Kg, of 5 g / 10 min, a density of 0.97 g / cm3, a melting point of 134° C. (hereinafter referred to “HDPE”). Thereafter, with 100 parts by weight of the PP-1 / HDPE composition, 5 parts by weight (3 parts by weight i...

example 2

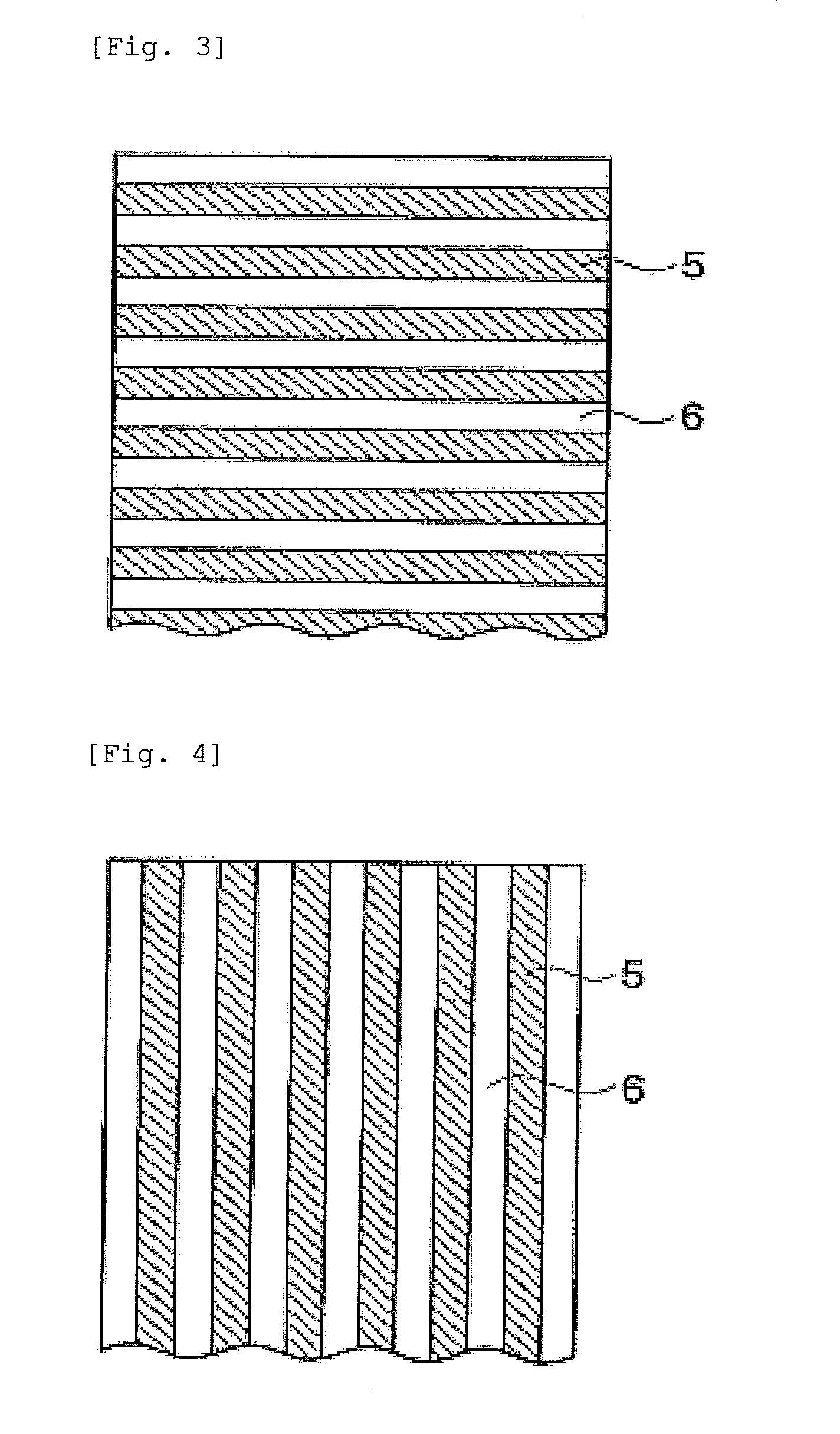

[0158]A mixed fiber spunbonded nonwoven fabric was prepared by the same manner as in Example 1, except that the conditions of the press processing performed in Example 1 were changed such that the heating temperature was 105° C. and the linear pressure was 30 N / cm, and the mixed fiber spunbonded nonwoven fabric was evaluated by the method as described above. The evaluation result is shown in Table 1. The touch (11) was evaluated as “I”. When this mixed fiber spunbonded nonwoven fabric was stretched in CD, good stretchability was obtained.

example 3

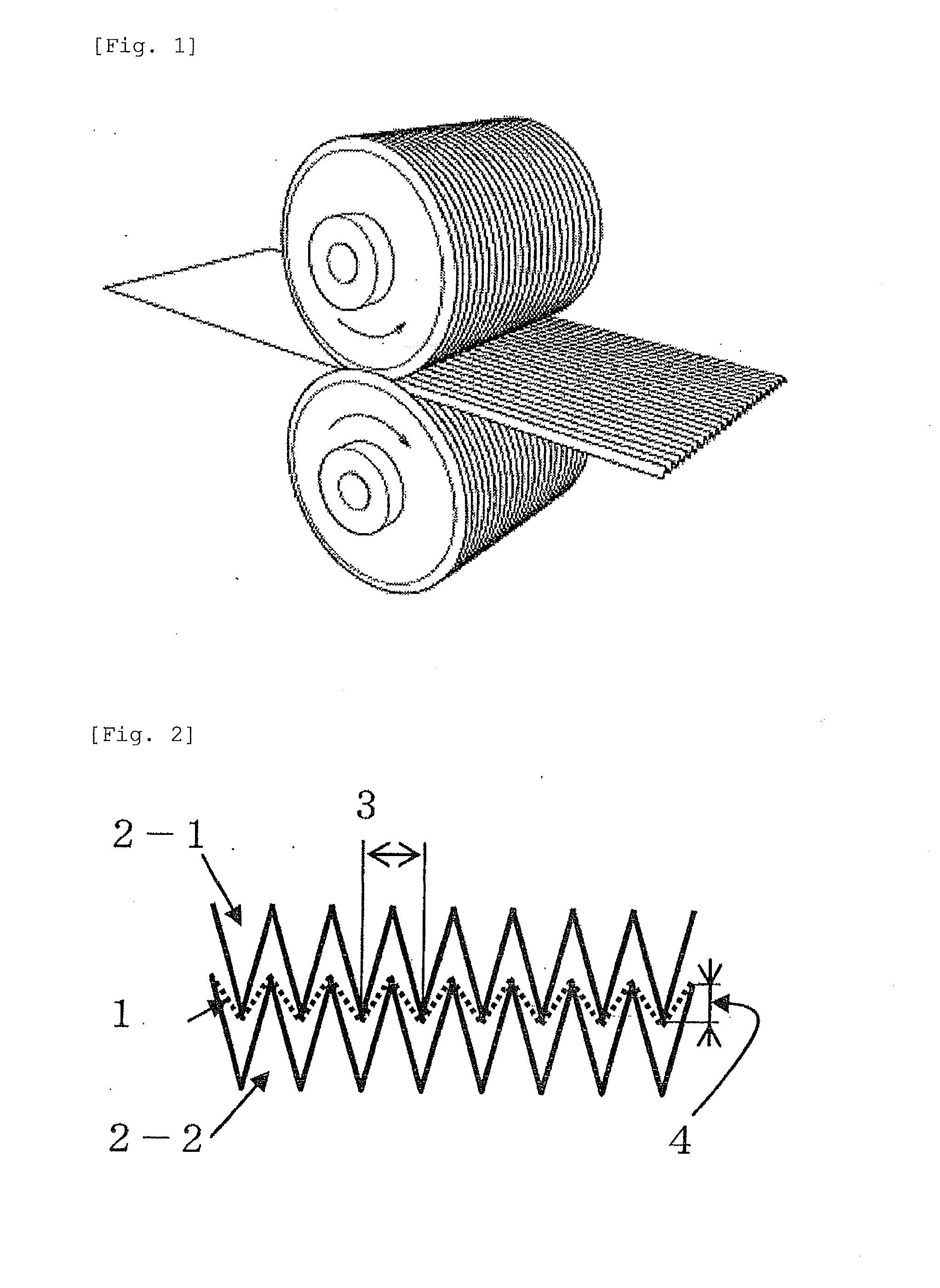

[0159]A mixed fiber spunbonded nonwoven fabric was prepared by the same manner as in Example 2, except that in the stretch processing performed in Example 2, the depth of the meshing of the rolls was adjusted to be 2.5 mm. The stretching ratio in CD obtained under the above conditions was 220% (a ratio of 2.2). This mixed fiber spunbonded nonwoven fabric was evaluated by the method as described above. The evaluation result is shown in Table 1. The touch (11) was evaluated as “I”. When this mixed fiber spunbonded nonwoven fabric was stretched in CD, good stretchability was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com