Resonator structures and method of making

a resonator and structure technology, applied in the field of resonator structures, can solve the problems of brittle ceramic nature of dielectric materials and challenges the processing of required resonator structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0040]The following examples illustrate methods and embodiments in accordance with the invention, and as such, should not be construed as imposing limitations upon the claims.

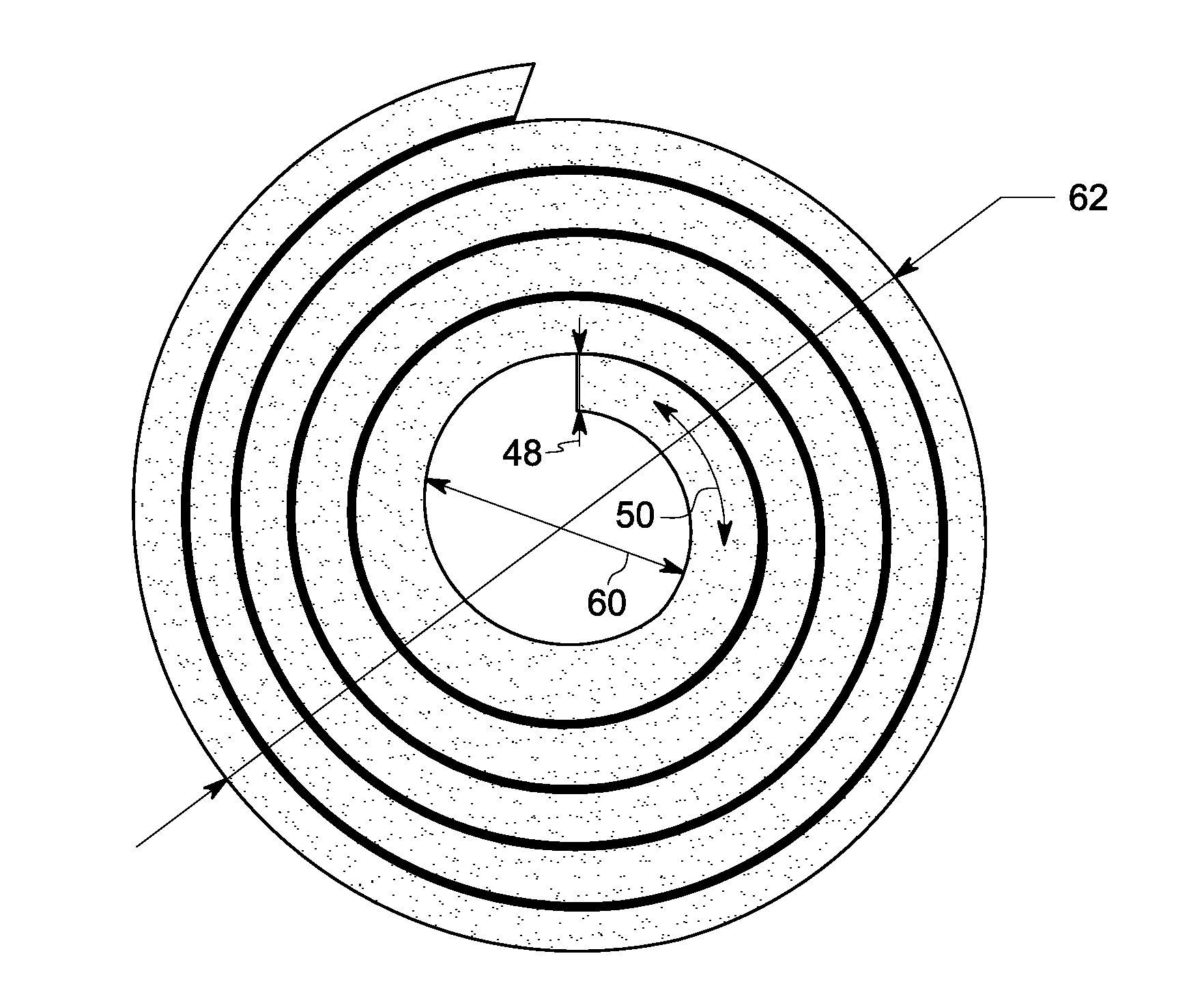

[0041]In one example, a sintered Swiss-roll structure 94 is prepared using the steps mentioned herein. A copper strip was prepared by cold working. The stresses of the cold worked metal strip were removed by heat treating the metal strip in an argon atmosphere at a temperature about 750° C., and cooling it at a slow rate. In an alternate example, the metallic strip was formed using hot working. The metallic strip formed by cold working or hot working was flattened using a hammer. The metallic surface was further rubbed using an emery paper of grit size 60 to prepare a rough surface configured to have sufficient interactions with the subsequent overlaying ceramic layer. Techniques such as sand blasting could be used alternatively for the surface preparation of metallic strip.

[0042]The surface-prepared metal stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com