Photosensitive resin composition, cured product thereof, and printed wiring board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

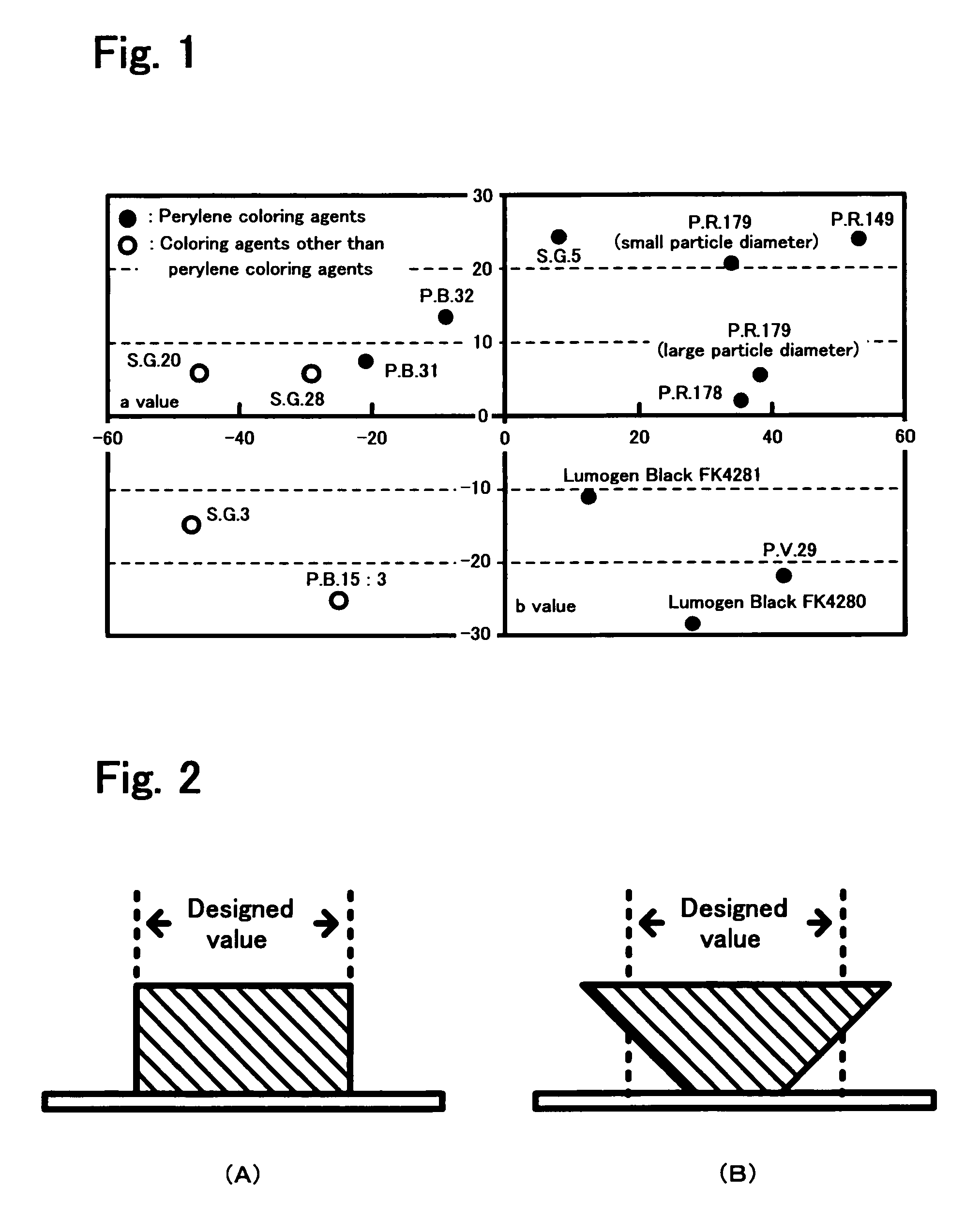

Image

Examples

examples

[0096]Hereinafter the present embodiment will be explained with referring to Examples and Comparative Examples, but it is needless to say that the present invention is not limited by the following Examples. In addition, unless otherwise indicated, the “part(s)” represents “part(s) by mass” in all of the following cases.

[0097]220 parts of a cresol novolak type epoxy resin (“EPICLON N-695” manufactured by DIC, epoxy equivalent amount: 220) was put into a four-necked flask equipped with a stirrer and a reflux condenser, and 214 parts of carbitol acetate was added thereto and dissolved by heating. Next, 0.46 part of hydroquinone as a polymerization inhibitor and 1.38 parts of triphenylphosphine as a reaction catalyst were added. This mixture was heated to from 95 to 105° C., 72 parts of acrylic acid was gradually added dropwise, and the mixture was reacted for 16 hours. This reaction product was cooled to from 80 to 90° C., 106 parts of tetrahydrophthalic acid anhydride was added, the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com