Process for the preparation of poly(alkylene terephthalate) employing in situ titanium-containing catalyst and compositions derived therefrom

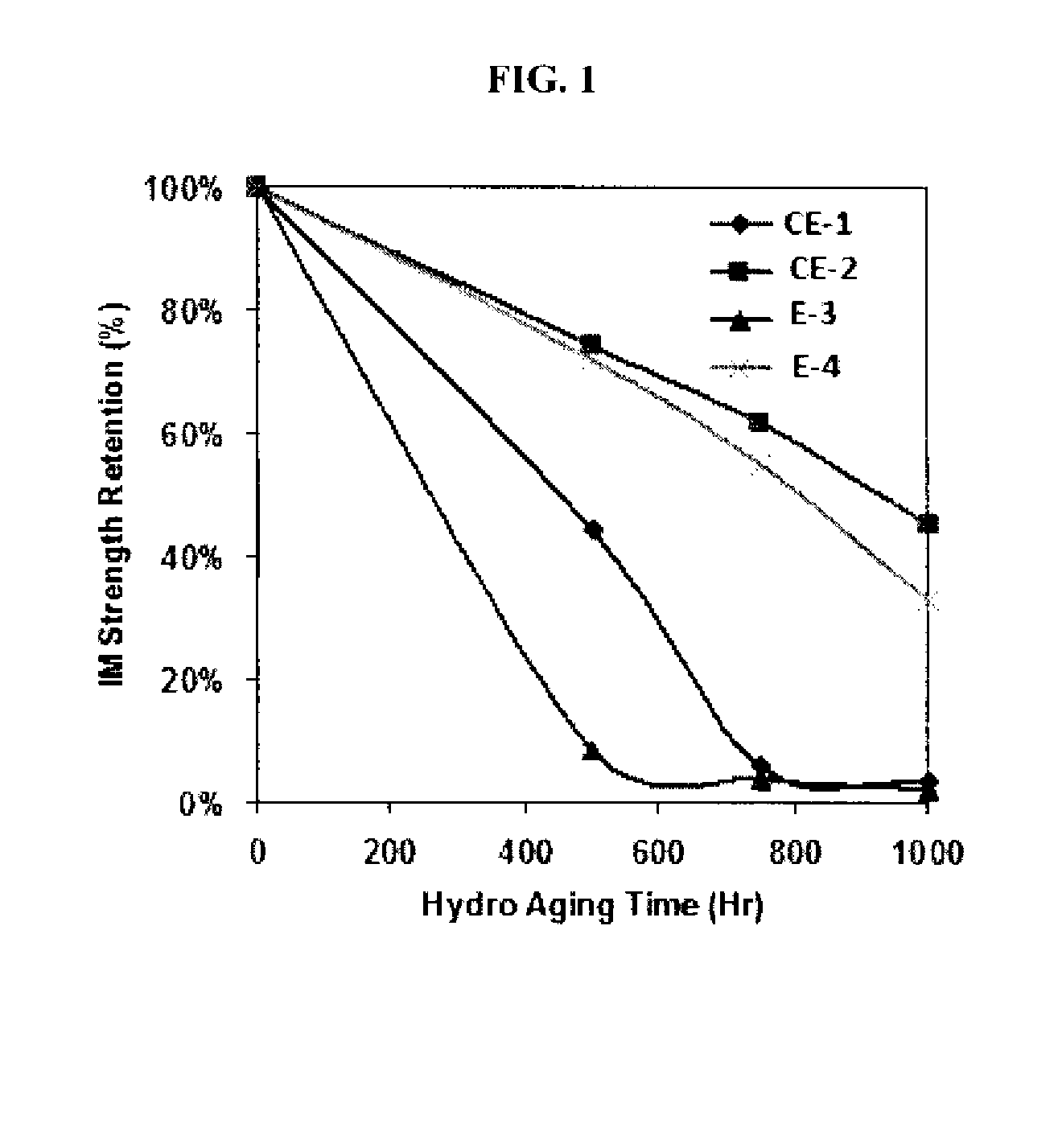

a technology of alkylene terephthalate and in situ titanium, which is applied in the direction of chemical recycling, etc., can solve the problems of unsatisfactory reactions, loss of mechanical properties, and increase hydrolytic instability, and contribute to a decrease in polymer molecular weight and greater hydrolytic instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0134]The following examples illustrate the scope of the invention. The examples and preparations which follow are provided to enable those skilled in the art to more clearly understand and to practice the present invention. They should not be considered as limiting the scope of the invention, but merely as being illustrative and representative thereof The examples are annotated as “E.” and comparative examples are annotated hereinafter as “CE”, employed the materials listed in Table 1.

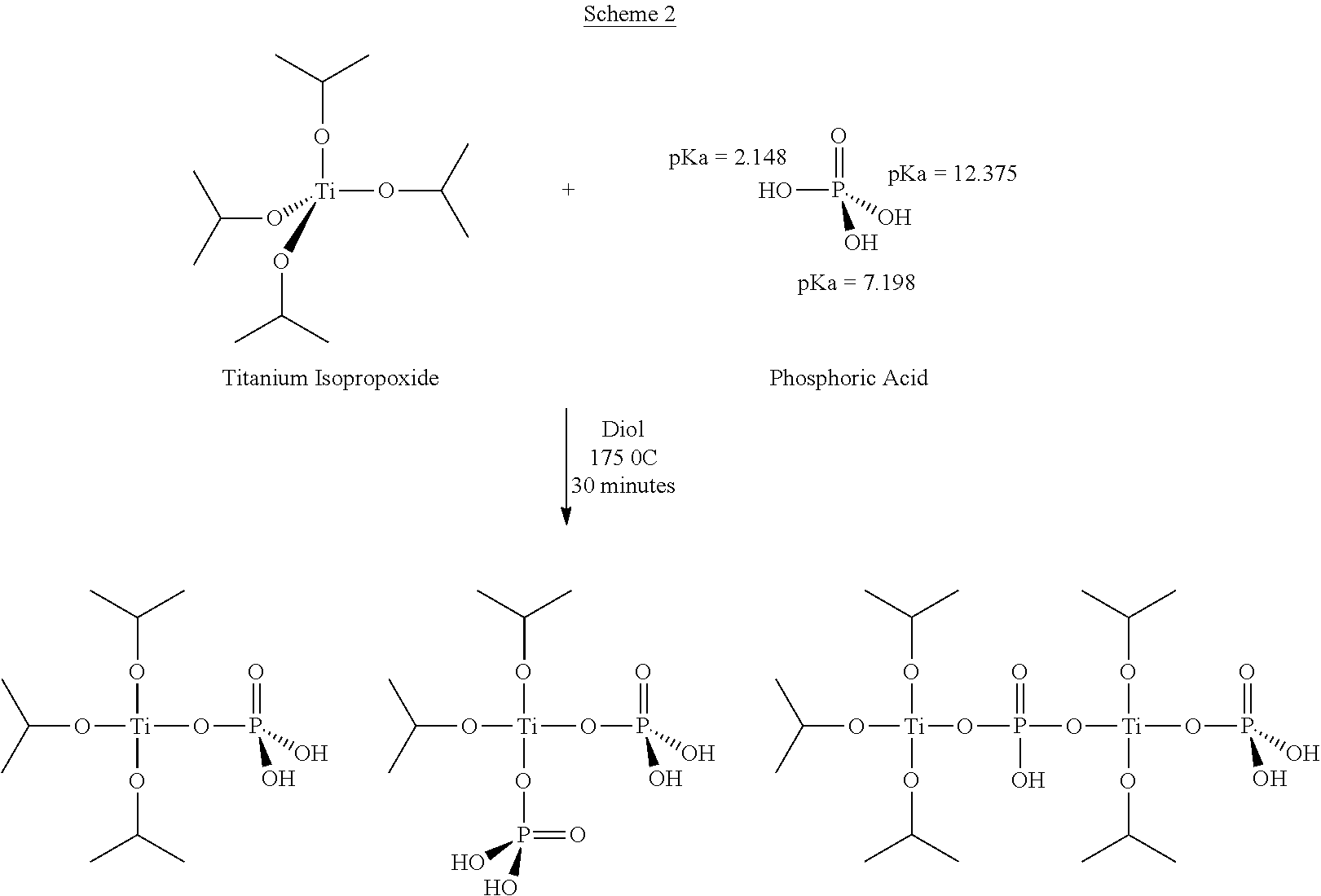

TABLE 1ComponentTrade Name and SupplierBDO1,4-Butanediol, CAS Reg. No. 110-6304, from BASF.PAPhosphoric Acid CAS Reg. No. 7664-38-2, from Acros.TPTTetraisopropyl titanate, CAS Reg. No. 546-68-9, fromDuPont, commercial Tyzor gradeDMTDimethyl Terephthlate, CAS Reg. No. 120-61-6., fromInvistaPE-IPolybutylene Terephthalate (PBT) sold by SABICInnovative Plastics as VALOX ® 315 with an intrinsicviscosity of 1.2 cm3 / g as measured in a 60:40phenol / tetrachloroethane.PE-IIPBT prepared by the process disclosed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com