Enhancement of beer flavor by a combination of pichia yeast and different hop varieties

a technology of pichia yeast and a combination of different hop varieties, applied in the field of beer brewing and enhancement of beer flavor, can solve the problems of wort-like taste, loss of aroma compounds, and relative minor contribution to overall beer flavor, and achieve the effect of enhancing the presence of desirable flavor compounds, such as esters and higher alcohols

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0116]Materials and methods

Fermentation Set-Up

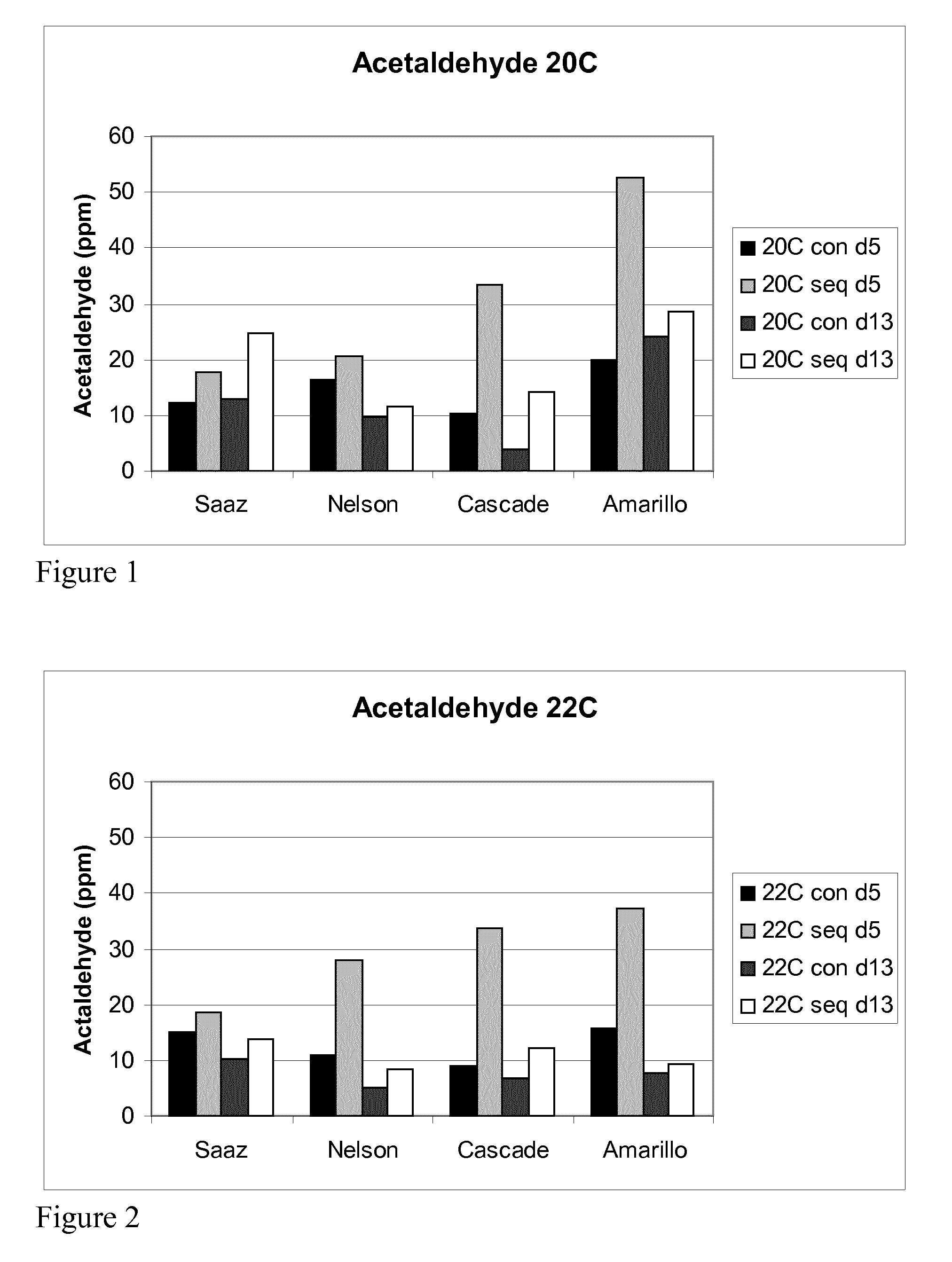

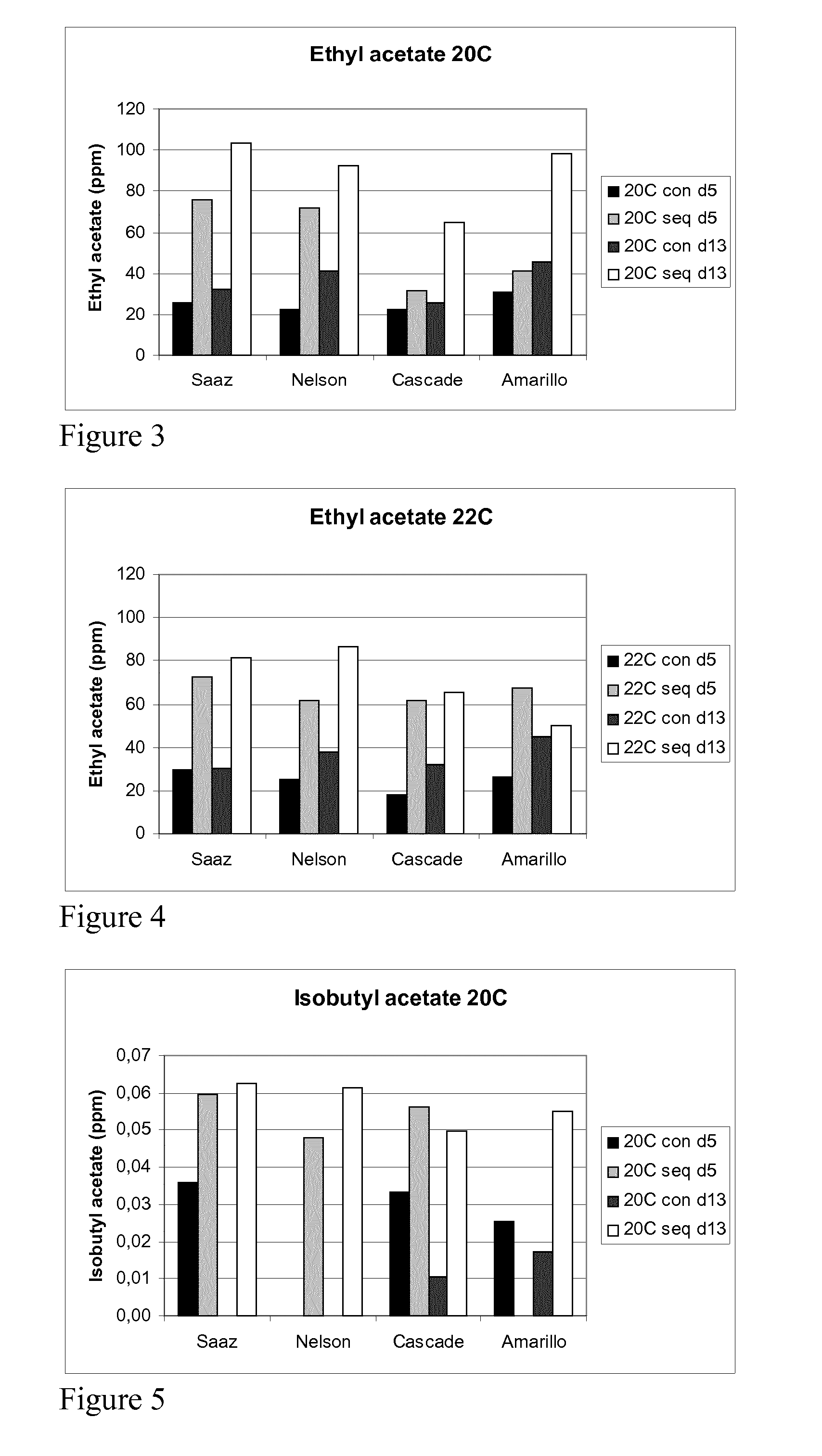

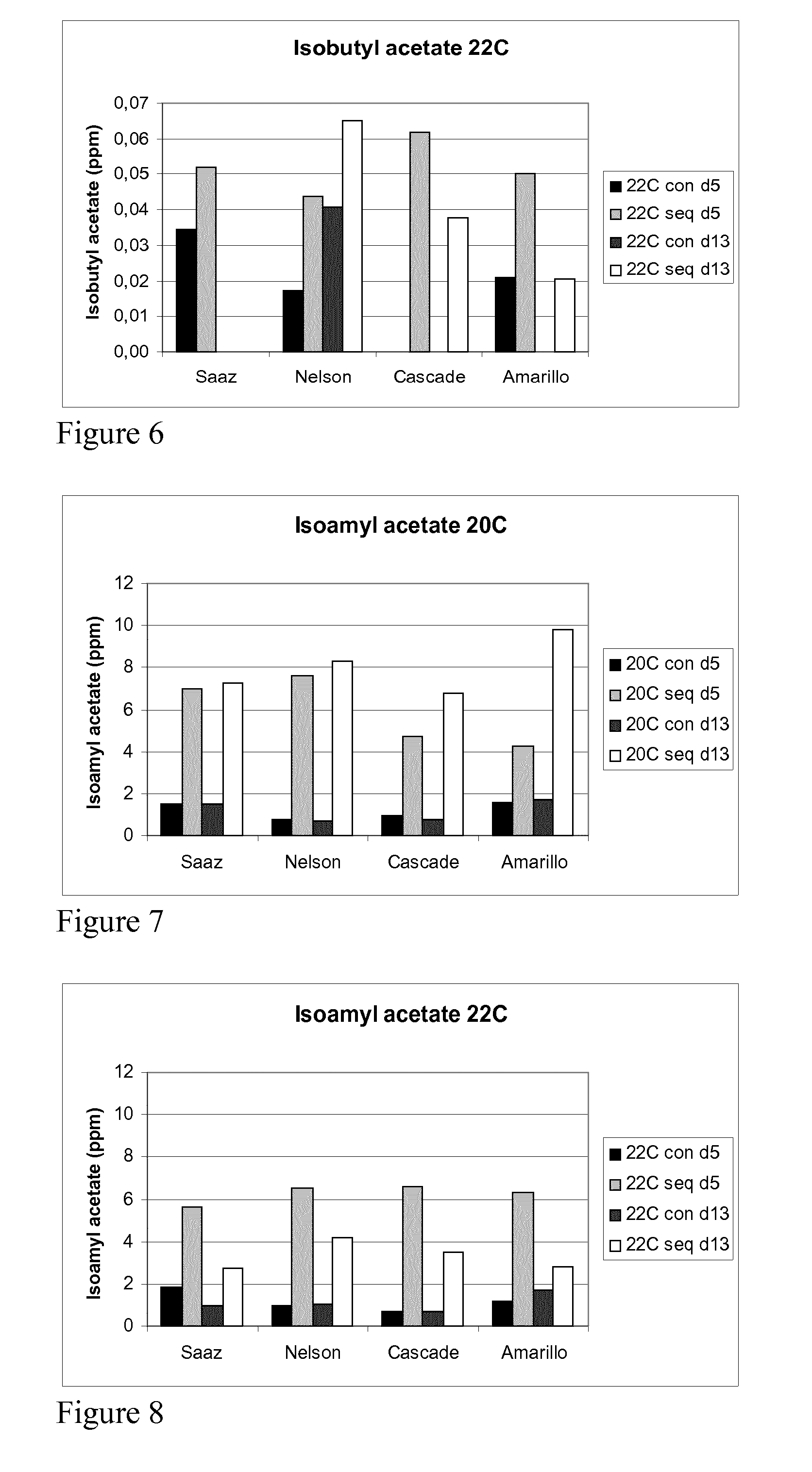

[0117]Lab-scale fermentation trials were carried out in 500 ml of wort. The wort was prepared with wheat malt extract (Brewferm). The malt extract was mixed with water to reach an initial sugar content of 10° P. 4 times 3 liter wort was boiled with 4 different hop varieties: Nelson Sauvin, Amarillo, Saaz and Cascade. Hop pellets were added in a closed coffee filter to the wort and this was boiled for 30 min to extract the hop flavor and to add bitterness to the beer. Hop pellets were added to reach 23 EBU. After boiling, the coffee filter was removed from the wort and the wort was transferred to 1 L bottles, which were closed by water locks.

[0118]Per hop variety, 4 fermentations were carried out. Two fermentation temperatures were used: 20° C. and 22° C. Per fermentation temperature, 2 different inoculations were done: one bottle was inoculated with Pichia kluyveri PK-KR1 (for sequential inoculation) and the second bottle was inoculated ...

example 2

[0134]A large-scale brewing trial was performed at a brewery to investigate the possibility of using Pichia kluyveri for the brewing industry, especially with regard to flavor.

Materials and Methods

Fermentation Procedure

[0135]The control beer and Pichia beer were made on a 15 HL scale in a brewery. The wort consisted of malt varieties typical for a pale ale beer, and the hop variety used was Cascade. 15 hl of wort was used to inoculate the Pichia kluyveri PK-KR1. Inoculation rate was calculated to be between 1-2 million cells per ml. Every day, a sample was taken for measurement of cell counts (see Table 3) and flavor analysis was performed on the final beer.

TABLE 3Cell count of Pichia kluyveri PK-KR1duringthe first 3 days of fermentation.DayCell count02.00E+0612.00E+0621.00E+0737.00E+05

[0136]At day 3, the normal brewing yeast was added (London Ale yeast from White Labs). The yeast was already used for making one beer and should therefore be optimal for this brew (2nd generation). Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com