System and method for controlling metabolite production in a microbial fermentation

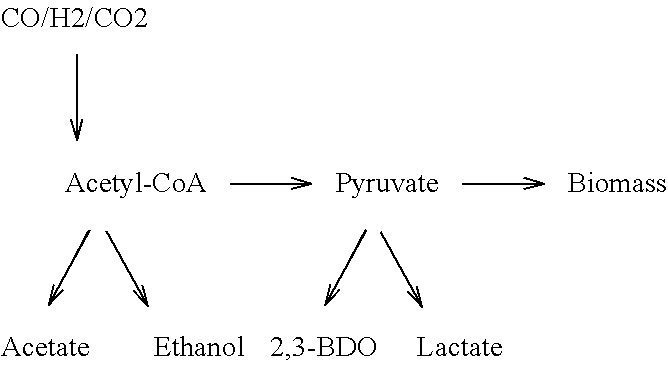

a technology of microbial fermentation and metabolite, which is applied in the direction of fermentation, waste based fuel, biofuels, etc., can solve the problems of inability to economically sustain starch or sucrose-producing crops for ethanol production in all geographies, the efficiency of ethanol production using such fermentation processes may be less than desirable, and the metabolism of the culture can be manipulated. , the effect of increasing the amount of carbon dioxid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Microarray Experiments

[0161]Fermentations with C. autoethanogenum DSM23693 were carried out in 1.5 L bioreactors at 37° C. and CO-containing as sole energy and carbon source as described below. A defined liquid medium containing per litre: MgCl, CaCl2 (2 mM), KCl (25 mM), H3PO4 (5 mM), Fe (100 μM), Ni, Zn (5 μM), Mn, B, W, Mo, Se (2 μM) was used for culture growth. The medium was transferred into the bioreactor and was supplemented with a B vitamin solution and reduced with 0.2 mM Cr (II) solution. To achieve anaerobicity the reactor vessel was sparged with nitrogen. Prior to inoculation, the gas was switched to a gas mixture containing 30% CO and 70% N2, feeding continuously to the reactor. The gas flow was initially set at 100 ml / min and the agitation was set at 300 rpm. Na2S was dosed into the bioreactor at 0.3 ml / hr. The agitation was increased to 900 rpm at 50 rpm intervals during the growth phase of the fermentation. After 0.8 day in the batch mode, the bioreactor ...

example 2

The Effects of Pressure on Fermentation

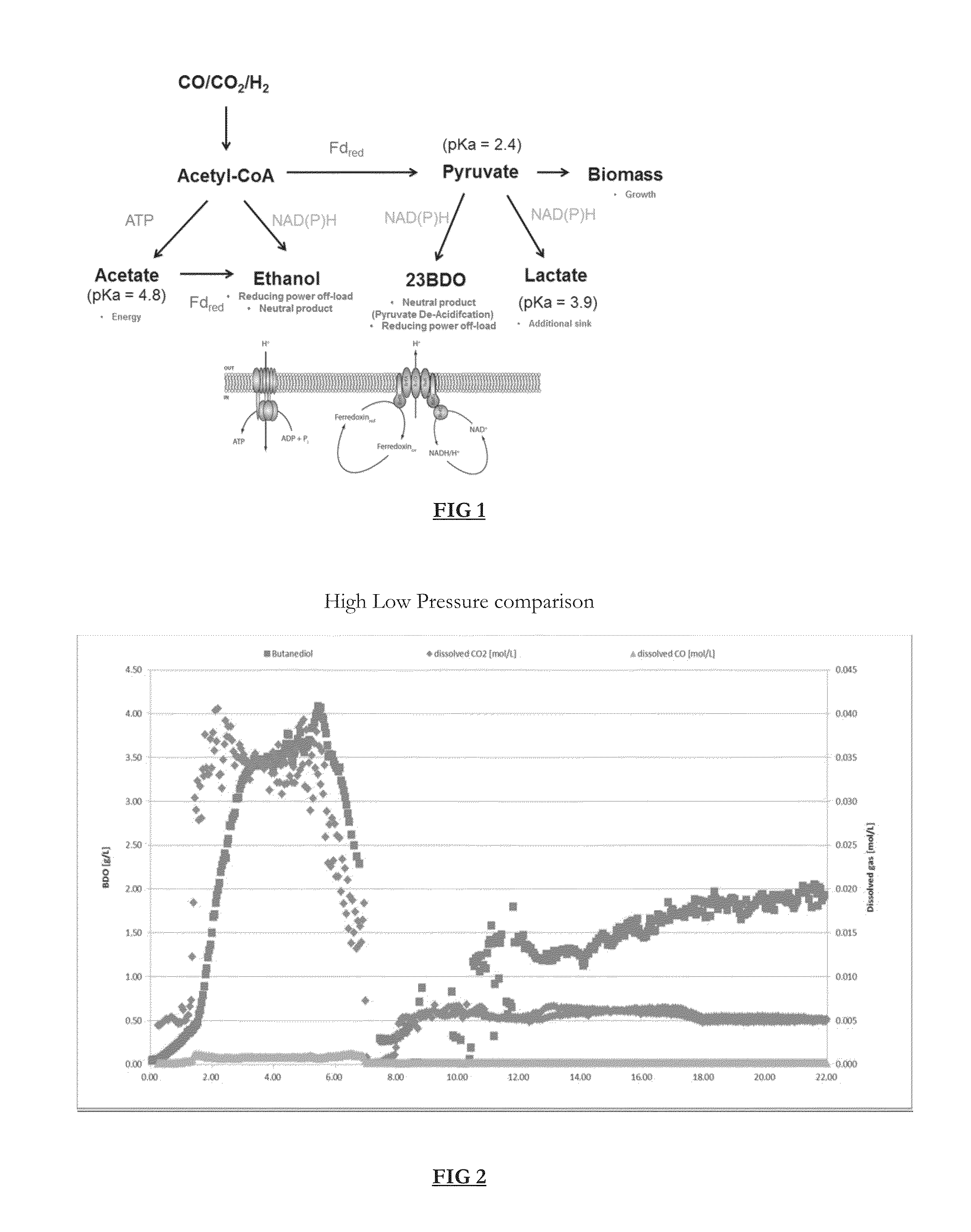

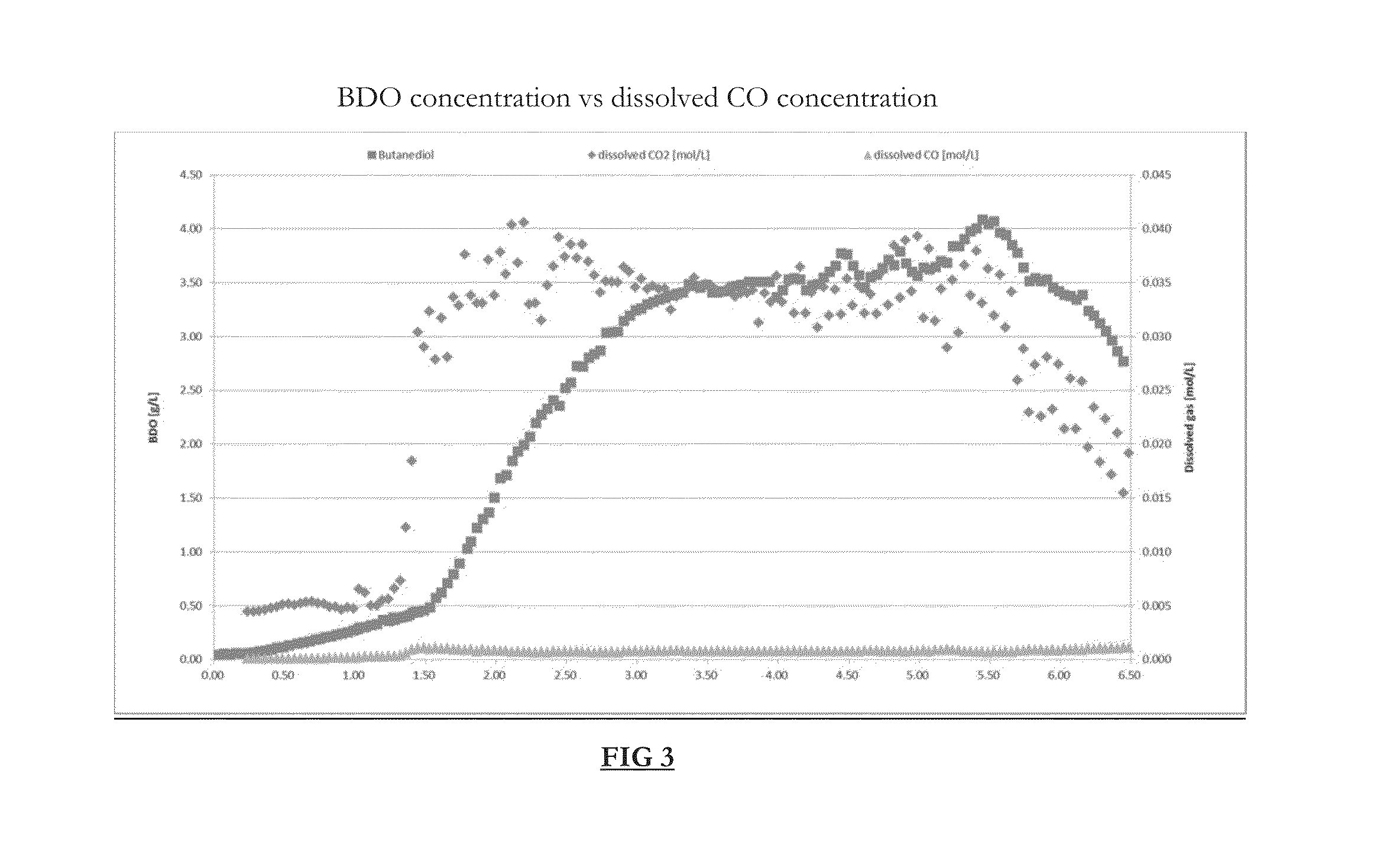

[0165]FIG. 2, FIG. 3 and FIG. 4 show results from fermentations run at both low and high pressure, to demonstrate the effects on both the amount of dissolved CO2 present in the fermentation broth, and the concentration of metabolites produced by the fermentation. In each of these experiments a bioreactor containing a liquid nutrient medium was inoculated with a culture of Clostridium autoethanogenum. A gaseous substrate comprising CO and CO2 was provided to the bioreactor.

[0166]FIG. 2 shows results from a first experiment, wherein the fermentation was run at different pressures, to determine the effect of pressure on the amount of dissolved CO2 and on the concentration of 2,3-butanediol (2,3-BDO) produced in the reactor.

[0167]FIG. 2 shows that at high pressure from days 0-6 (320 kPag in the headspace of the reactor, and about 420 kPag at the bottom of the reactor) both the amount of dissolved CO2 in the fermentation broth, and the concentration...

example 3

Increasing Dissolved CO2 Concentrations

[0170]A set of experiments was performed which demonstrated that the level of dissolved CO2 in the fermentation resulted in increased production of 2,3-butanediol.

3A: Changes in CO2 Inlet Concentration as a Way of Increasing 2, 3 BDO Production

[0171]During this experiment the CO2 concentration of the inlet gas to the fermentation broth was changed from 0% to 25% in one step after 28 days of operation. The CO uptake was kept constant for the entire experiment and the concentration of CO was kept at 30% in the inlet gas. As shown in FIG. 5 a large increase in 2,3 butanediol production was observed when the CO2 was changed from 0% to 25%.

[0172]FIG. 6 depicts the changes in the CO2 concentration in the fermentation broth between days 25-31. At day 25 the amount of CO2 in the inlet stream provided to the fermentation was 0%. At day 28 the CO2 concentration of the inlet stream was increased to 25%. FIG. 6 clearly shows that that CO uptake stayed the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com