These prior art forms are not insulated and therefore concrete is exposed to the environment.

In the next few days, most of the initial concrete

moisture is also lost from the concrete.

Therefore, the two elements required to fully

hydrate the

cement are lost during the initial stage of concrete curing.

Thus, the

cement may never fully

hydrate, and, therefore, may never achieve maximum strength.

Portland cement manufacture causes environmental impacts at all stages of the process.

Slag cement and

fly ash generate relatively low amounts of heat of hydration, which result in extremely slow

setting time and strength

gain.

Such concrete is also less permeable, and, therefore, structures built with

slag cement and fly ash have far longer service lives.

However, only a relatively small percentage of

slag is used to make slag cement in the USA.

Therefore concrete made with pozzolanic materials are seldom used due to their slower curing process.

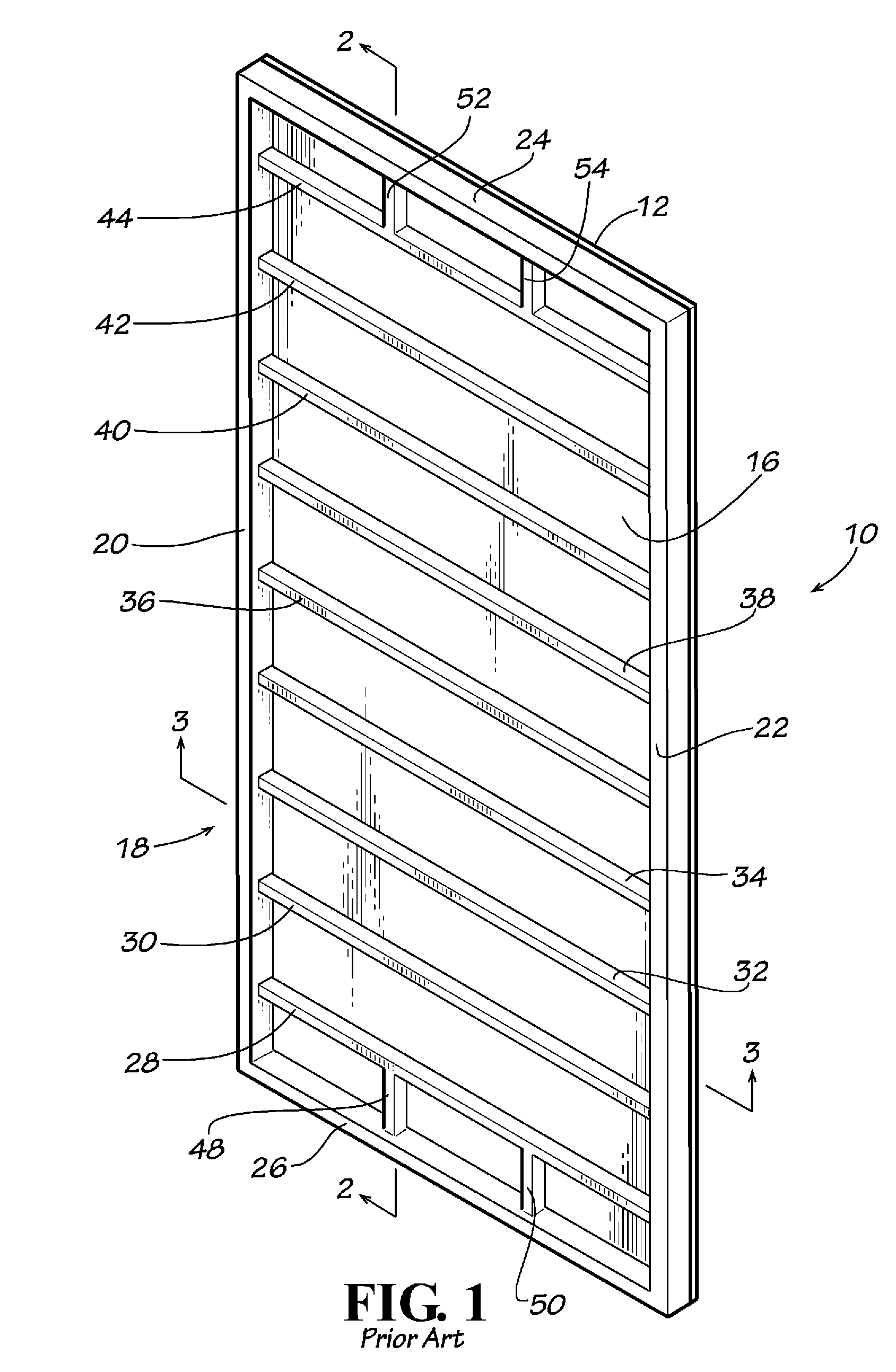

These forms are not insulated which means that concrete is exposed to the elements during the initial portion of the curing process.

This often makes the curing of the concrete a slow process and the ultimate strength difficult to control or predict.

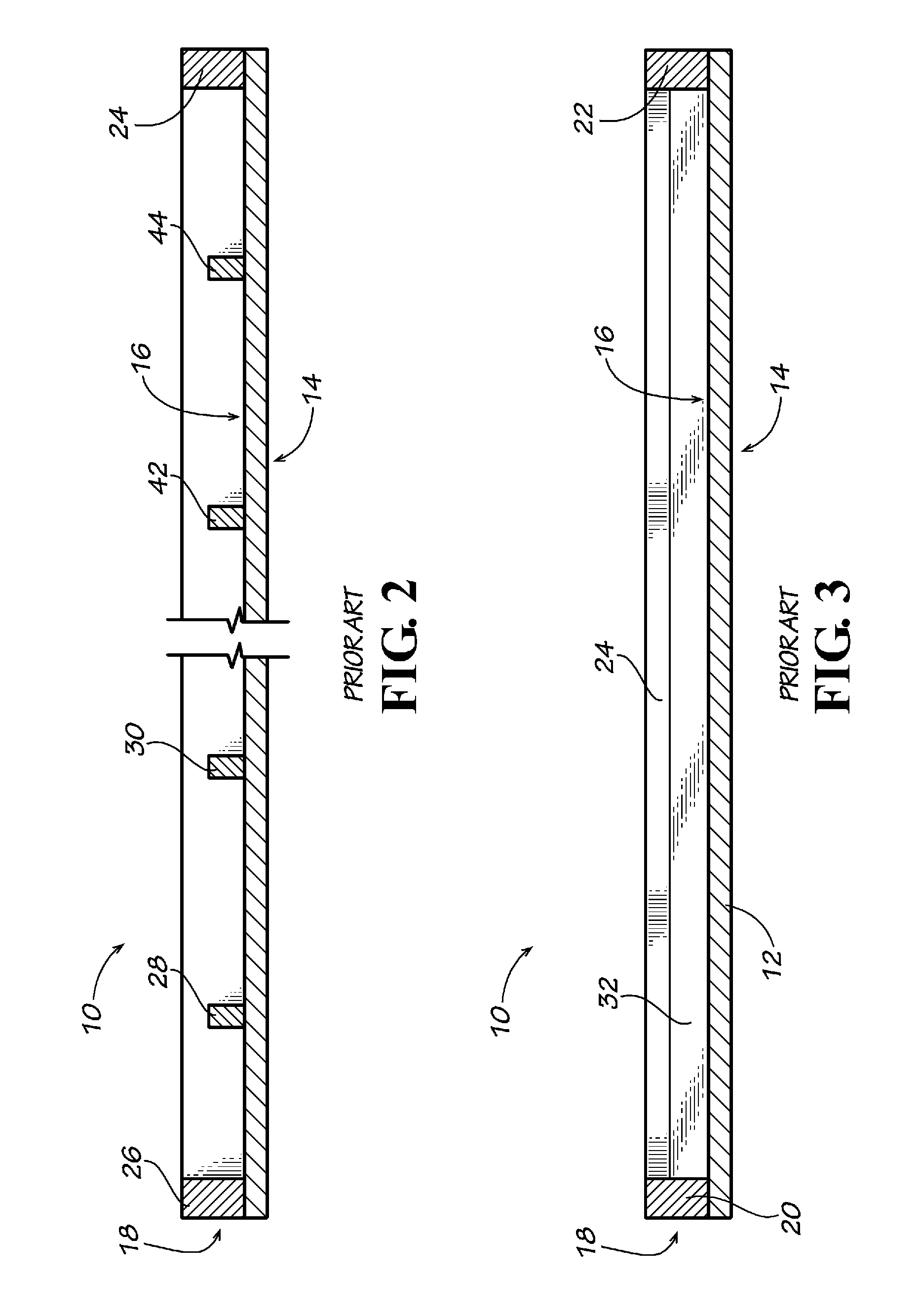

Initially, the hydration process produces a relatively large amount of heat.

Also, due to the heat loss to the environment the concrete placed in conventional forms does not reach its maximum potential temperature.

At the same time,

moisture in the concrete is lost to the environment.

In conventional forms, both heat and

moisture are lost in a relatively short time, which makes it difficult, or impossible, for the cementitious material to fully

hydrate, and, therefore, the concrete may not achieve its maximum potential strength.

Therefore, heat produced within the concrete form or mold due to the hydration process usually is lost through a conventional concrete form or mold relatively quickly to the environment.

This initial relatively large

temperature drop may result in significant concrete shrinkage and / or thermal effects which can lead to concrete

cracking.

The remainder of the curing process is then conducted at approximately ambient temperatures, because the relatively small amount of additional heat produced by the remaining hydration process is relatively quickly lost through the uninsulated concrete form or mold.

Failure to cure the concrete under ideal temperature and moisture conditions affects the ultimate strength and durability of the concrete.

In addition the temperature

gain and loss in the first few days of concrete curing creates thermal stresses within the concrete.

At the time that the concrete reaches its

maximum temperature, usually 8-16 hrs, the concrete is in a relatively weak state and cannot withstand the thermal stresses very well.

The further heat loss and

gain due to the ambient temperature fluctuations from day and night places additional thermal stresses upon the concrete and further contributes to temperature

shrinkage cracking.

While initially temperature

shrinkage cracking is on a nano scale, with time, the nano cracks develops into fractures that weaken the concrete and shorten its lifespan.

In colder weather, concrete work may even come to a halt since concrete will freeze, or not gain much strength at all, at relatively low temperatures.

Under conventional forming and curing methods, the concrete takes a relatively long time to fully hydrate the cementitious materials.

However, moisture curing for 28 days is seldom possible to administer in commercial practice.

Therefore, concrete poured in various applications in conventional forms seldom develops it maximum potential strength and durability.

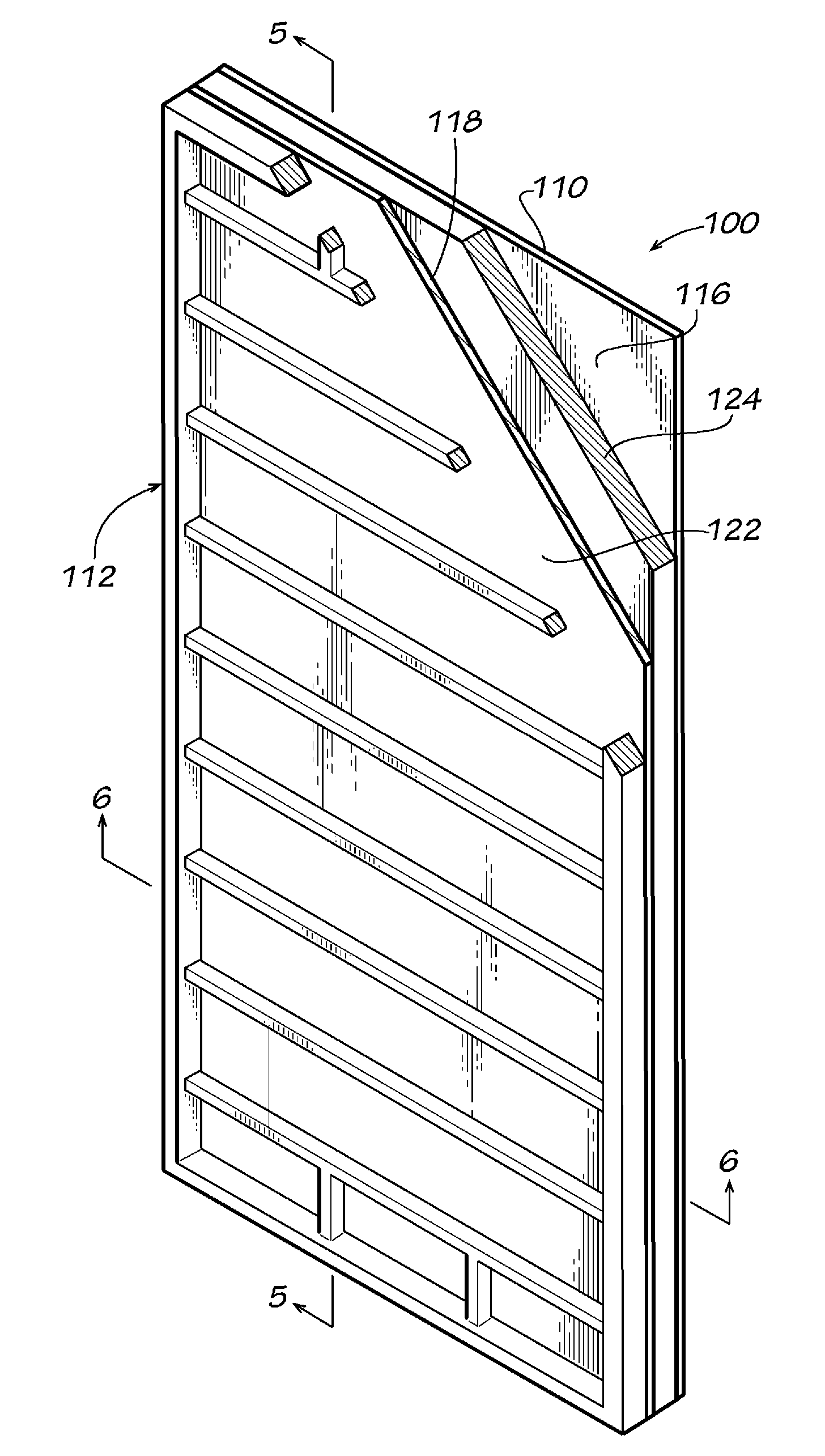

However, these insulated concrete forms are stay in place concrete forms whereby the insulating panels are attached to the concrete and are not easily removed.

In addition if these insulated panels are removed from the concrete, they are usually damaged and not able to be reused.

Although insulated concrete forms work well and provide many benefits, concrete contractors and architects are somewhat reluctant to use them or specify them.

Especially, stay in place insulated concrete forms cannot be used for applications that require removal of the formwork.

Under conventional forming and curing methods, the concrete takes a relatively long time to fully hydrate the cementitious materials.

However, moisture curing for 28 days is seldom possible to achieve in commercial practice.

Therefore, for concrete poured for various applications it can be very difficult, or impossible, to achieve its maximum potential strength and durability.

It is believed that prior art concrete forms have not been proposed or used as a method to cure concrete or to improve the performance and

properties of concrete.

Login to View More

Login to View More