Elongated steel element comprising a ternary or quaternary brass alloy coating and corresponding method

a technology of ternary or quaternary brass alloy and steel element, which is applied in the direction of tyre parts, non-conductive materials with dispersed conductive materials, textiles and paper, etc. it can solve the problems of early rubber ageing, accelerated oxidation of diene rubber molecules, and increased crack growth rate of cobalt, so as to improve adhesion and reduce the adhesion performance , the effect of improving the adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

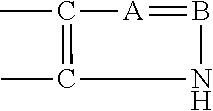

Image

Examples

Embodiment Construction

[0059]Two sample steel wires with a diameter of 1.98 mm are provided with a ternary alloy coating as follows:[0060]i) pickling in a H2504 solution to clean the surface of the steel wire;[0061]ii) electroplating with copper from a Cu2P2O7 solution; solution contains 25 g / l copper and 180 g / l pyrophosphate; current density is 8.6 A / dm2 or higher for a higher copper content;[0062]iii) electroplating cobalt from a CoSO4 solution; solution contains 40 g / l cobalt and current density is 22 A / dm2;[0063]iv) electroplating with zinc from a ZnSO4 solution; solution contains 50 g / l zinc and current density is 8.8 A / dm2 or lower for a lower zinc content;[0064]v) applying a thermal diffusion process to create the ternary alloy Cu—Co—Zn;[0065]vi) removing excess of ZnO formed during diffusion process via a dip in an acid;[0066]vii) rinsing and drying.

[0067]Steel wire 1 has following coating composition: 63.5 wt % Cu, 4.0 wt % Co, the remainder being Zn.

[0068]Steel wire 2 has following coating comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com