Container and Method of Manufacture of Container

a container and container technology, applied in the field of container and container and container manufacturing method, can solve the problems of long and time-consuming procedure, unstable and short-lived solution of many biological species, and long-term stability of the solution, so as to achieve less waste and less packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

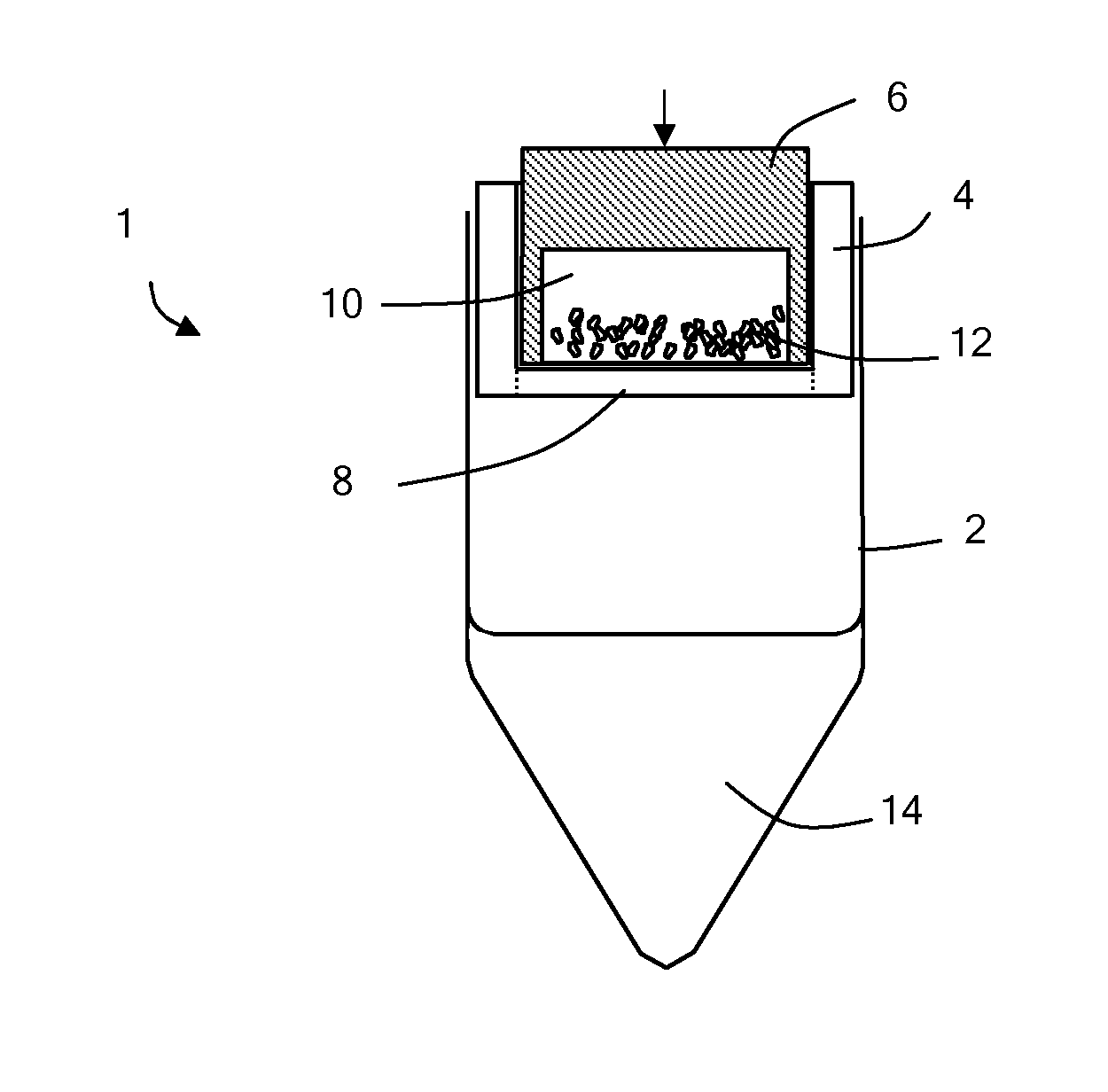

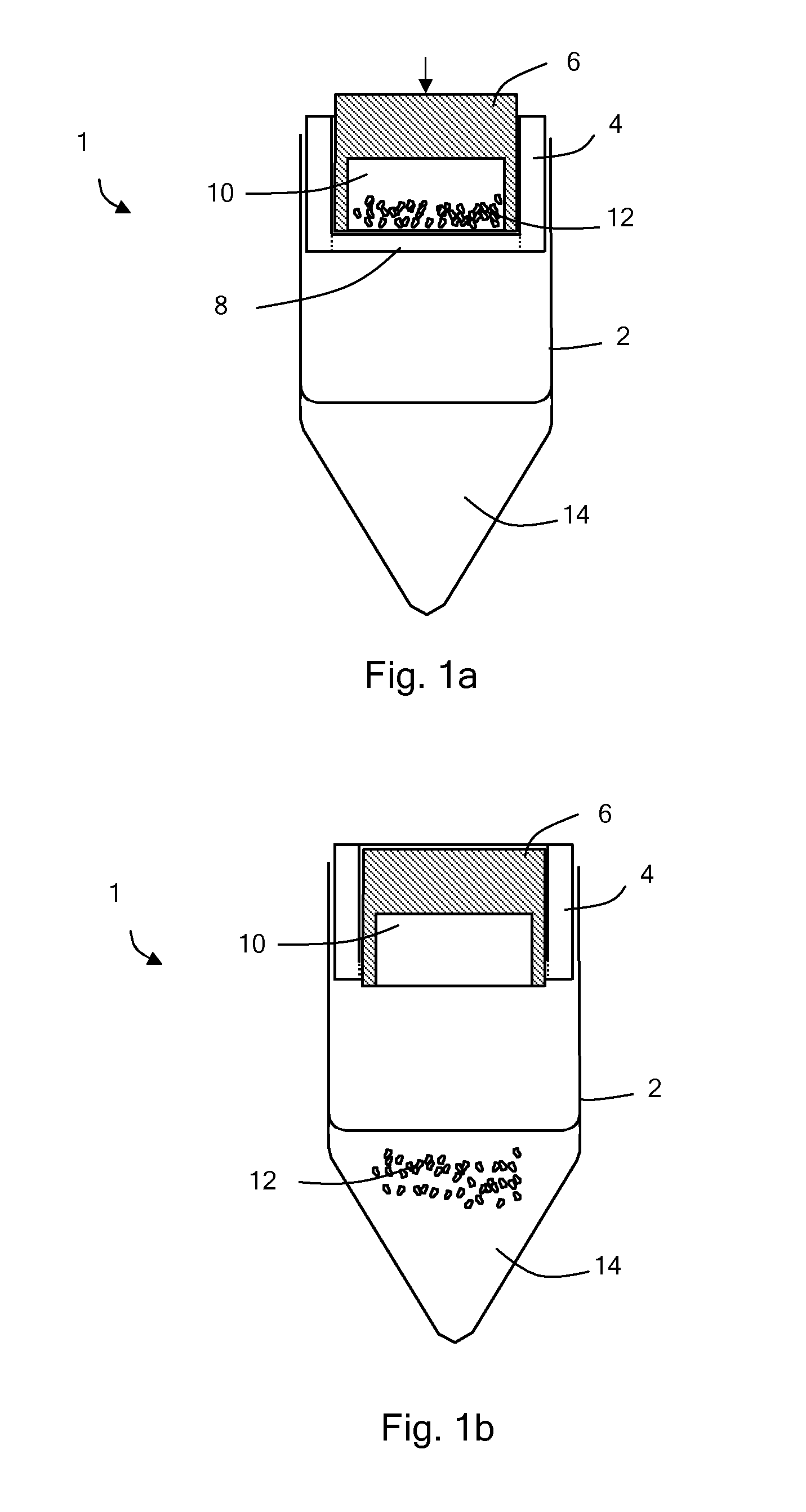

[0044]With reference to FIG. 1, a pre-loaded vial 1 comprises a vial (acting as a container) 2 and a vial cap 4 (acting as a closure). The vial cap comprises a piston 6, a base 8 (acting as a frangible member) and a recess 10 retaining a lyophilised vaccine 12 (acting as an active agent). The vial retains a diluent 14 (for example, saline solution) suitable for solubilising the lyophilised vaccine. The piston of the vial cap defines apertures, which are sealed after manufacture.

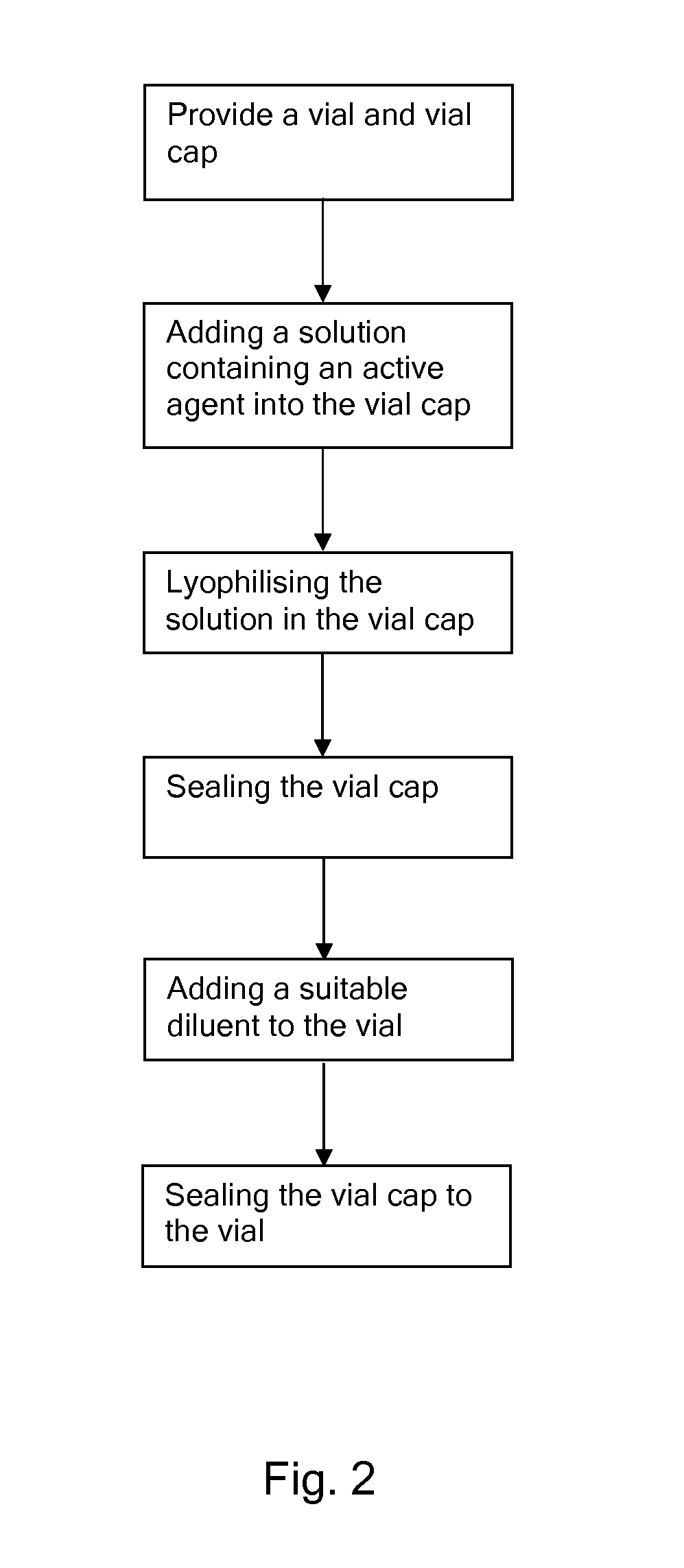

[0045]The pre-loaded vial is manufactured by the following method, shown in FIG. 2.

[0046]The vial and vial cap are sterilised. A solution of the vaccine is prepared and one dose of the vaccine is placed into the recess of the vial cap. The recess of the vial cap is then covered by the piston. The apertures defined by the piston allow the recess of the vial cap to be ventilated. The vaccine solution within the vial cap is then lyophilised. That is, the vaccine solution is frozen and then warmed in vacuum to al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com