Purification System Comprising Continuous Reactor and Purification Method Using Continuous Reactor

a technology of purification system and continuous reactor, which is applied in the direction of vibration crystallization, separation process, filtration separation, etc., can solve the problems of difficult to obtain crystals having a transmission of 95% or higher, shorten the regenerative cycle of resin, and difficult to achieve dark spots in the device. , the effect of prolonging the life of the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

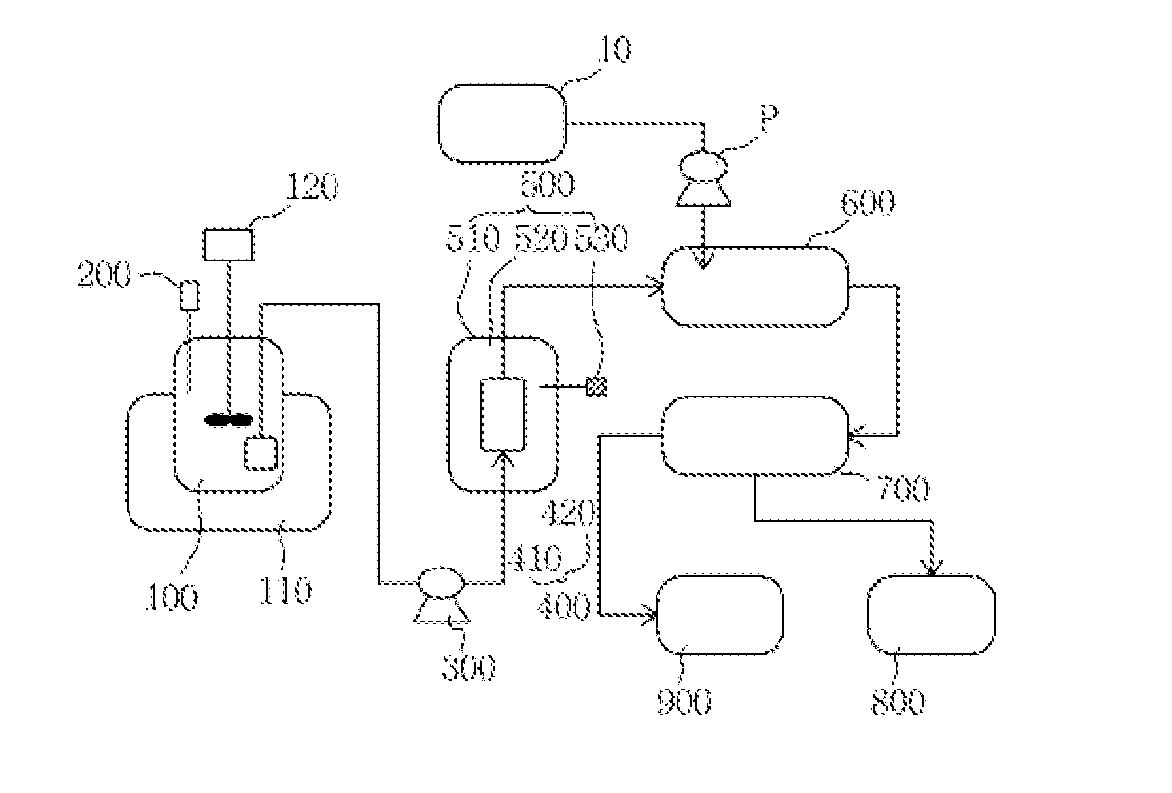

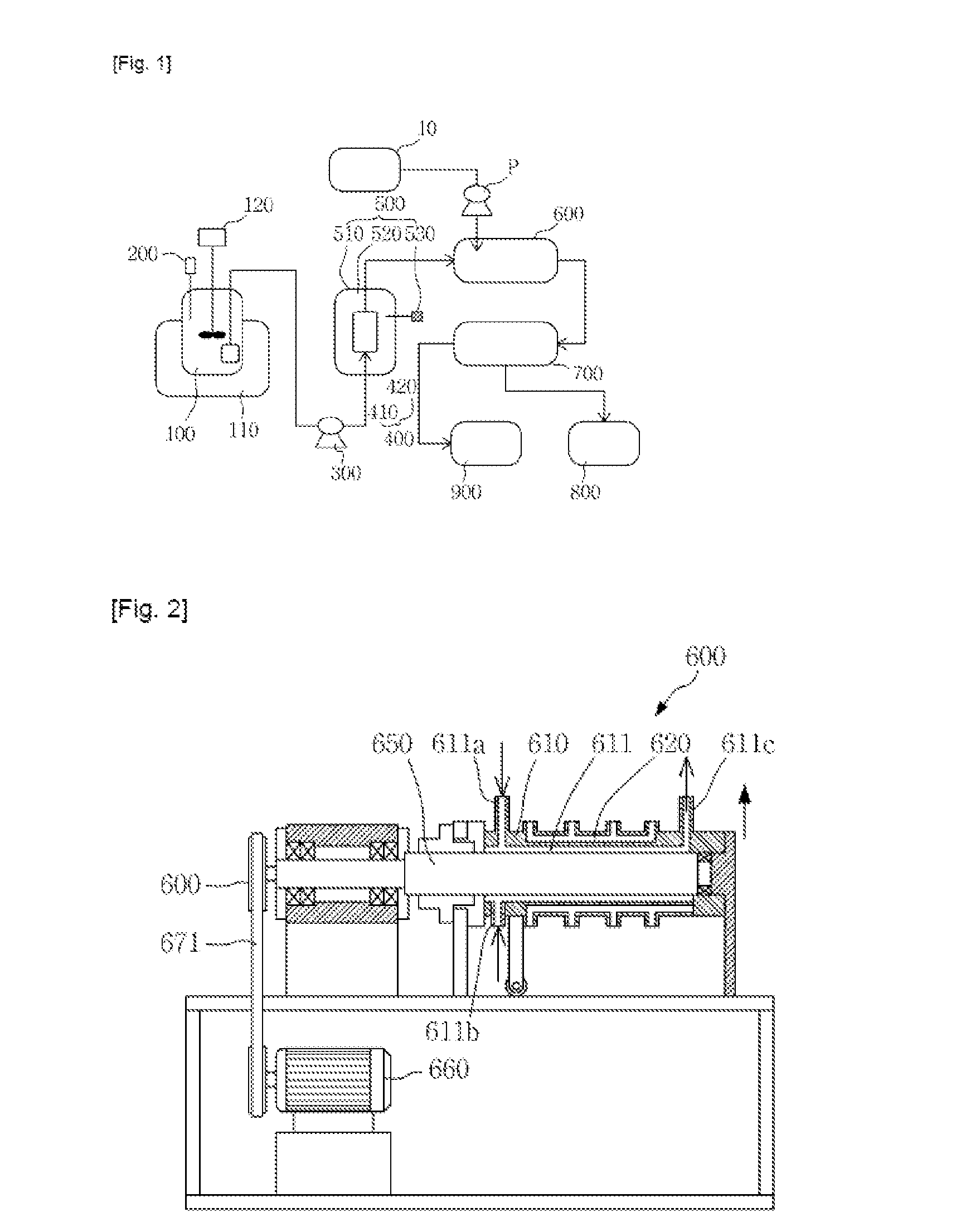

[0029]The purification system shown in FIGS. 1 to 3 comprises a reactor. This purification system comprises a solution storage tank 100, an ultrasonic disperser 200, an air compressor 300, a filter cartridge 400, a temperature controlling unit 500, a continuous reactor 600, an organic material separator 700, an organic material storage chamber 800 and a correction module 900.

[0030]The solution storage tank 100 serves to store a solution of an organic material (OLED) in an organic solvent. The concentration of the organic material in the organic solvent is preferably 100 g / L or lower, and if the concentration of the organic material is higher than the upper limit of the above concentration range, a crystallization reaction will be delayed or it will be difficult to obtain the desired purity. As used herein, the term “organic material” refers to any material that is provided between the anode and cathode of an organic electroluminescent device. Examples of an organic material or organ...

embodiment 2

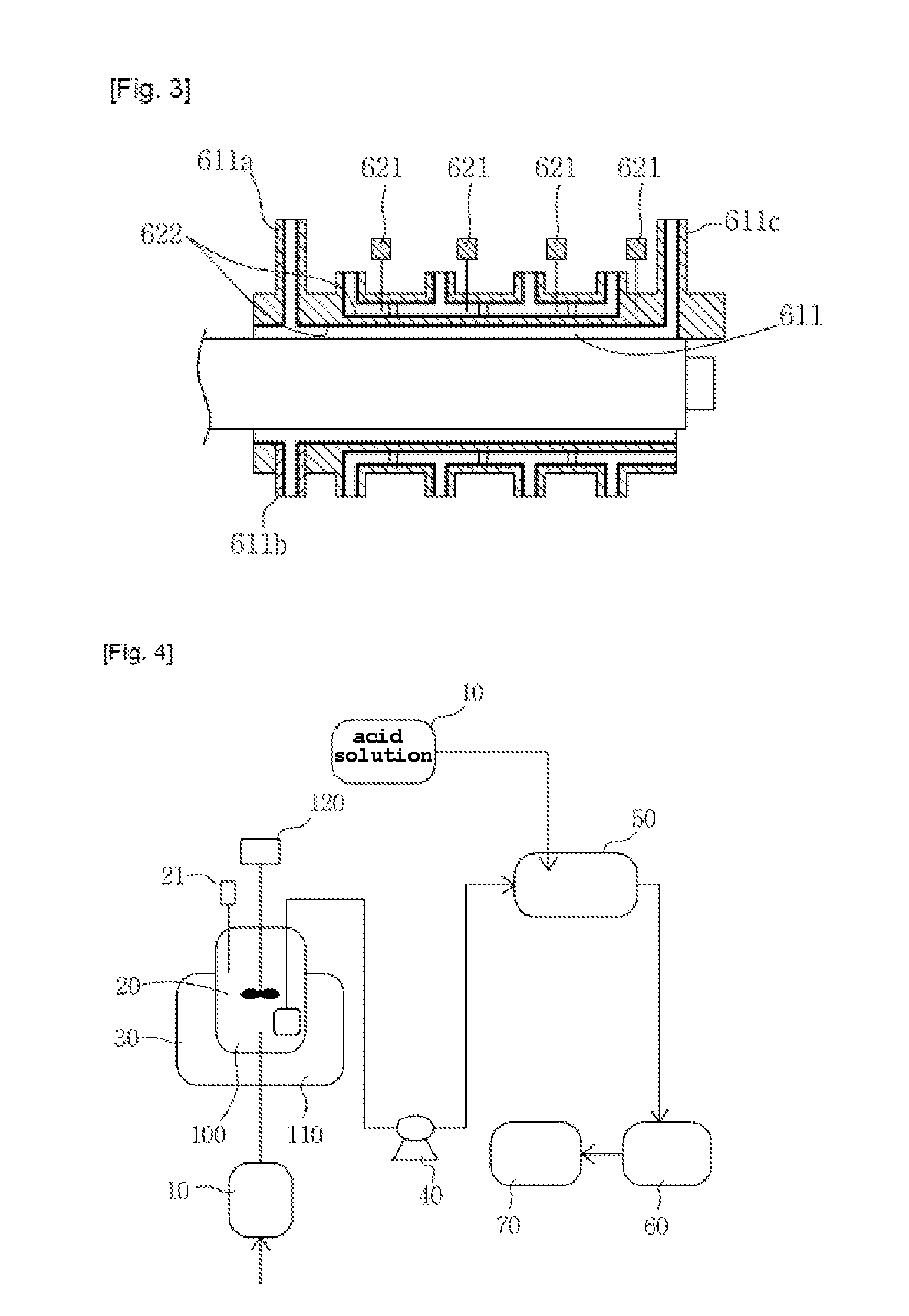

[0054]Hereinafter, a system for purifying tryptophan will be described which comprises, in addition to the above-described continuous reactor, storage tank, stirrer, disperser and heating jacket, a dewaterer and a dryer.

[0055]As shown in FIG. 4, the system for purifying tryptophan comprises a filter 10 for filtering solids, a storage tank 20, a heating tank 30, an air compressor 40, a continuous reactor 50, a dewaterer 60 and a dryer 70.

[0056]The filter 10 for filtering solids is configured to filter out solids from a tryptophan solution while allowing the solution to pass through the filter. Herein, the filter 10 has a mesh size (or pore size) of 0.1 μm or larger, and preferably 0.1-0.5 μm, so that it filters out solids having a size of 0.5 μm or larger from the tryptophan solution and allows only fine solids having a size of less than 0.5 μm to pass therethrough. As a result, the filter 10 performs a first purification step. The storage tank 20 serves to store the tryptophan solut...

embodiment 3

[0062]A method for purifying tryptophan according to the present invention is performed in the following order (see FIG. 5).

[0063]Step 1 is a solid removal step (S10).

[0064]In the solid removal step, the tryptophan solution is passed through a filter to remove solids having a size larger than a predetermined size, before it is stored in the storage tank.

[0065]The filter that is used in the solid removal step preferably has a mesh size (or pore size) of 0.1-0.5 μm. Thus, dissolved solids having a size of 0.5 μm or larger, contained in the tryptophan solution, are filtered out, and thus the tryptophan solution contains only fine solids having a size smaller than 0.5 μm.

[0066]Step 2 is a pH adjusting step (S20).

[0067]In the pH adjusting step, caustic soda (NaOH) is introduced into the storage tank to adjust the pH of the tryptophan solution. Herein, the pH is preferably adjusted to 3-11.

[0068]Step 3 is a temperature controlling step (S30).

[0069]In the temperature controlling step, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com