Solar receiver

a solar receiver and receiver technology, applied in the field of solar energy systems, can solve the problems of affecting the safety of solar heat collectors, affecting the performance of solar energy collectors, and requiring re-alignment, so as to enhance the precision of the formed surface, the effect of enhancing the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

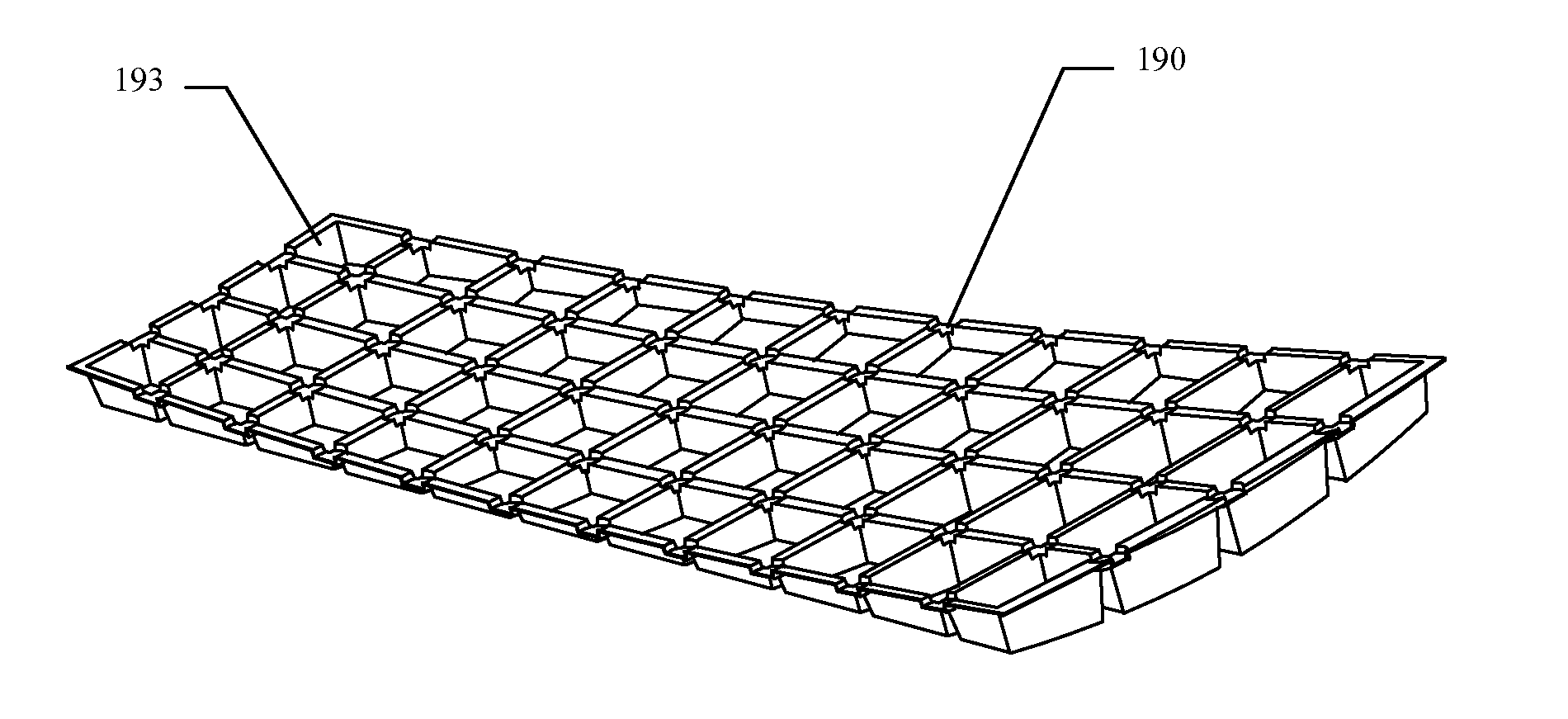

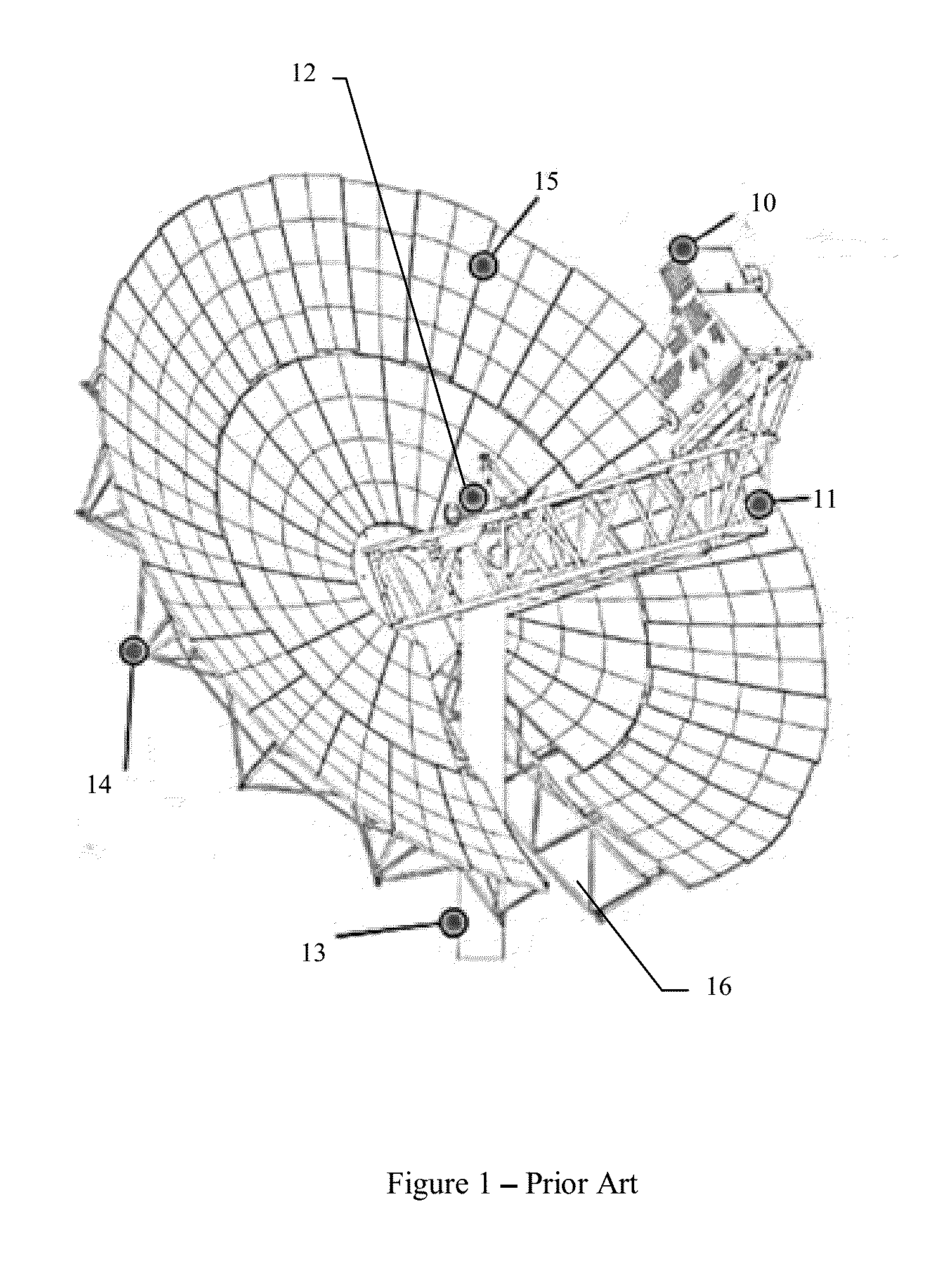

[0199]FIGS. 19a-c shows several embodiments of the core with different tile and cup geometries. In the first embodiment shown (FIG. 19a), the tile core is implemented with trapezoid or rectangular cups [193] instead of triangular one. The packing of the cups is more efficient than that of the triangles, and their fit to the side edges of the tile is more consistent and uniform. In this embodiment, reliefs [190] are formed to alleviate thermal expansion conflicts between the core material and the membrane material. The reliefs are formed by adding corresponding depressions to the vacuum mold.

[0200]The next embodiment shown (FIG. 19b, front, and FIG. 19c, back) is of a core for a rectangular almost-flat reflector panel (such as is used with Heliostats) which uses round cups [191], and additionally has sidewalls [192] formed during the vacuum forming process, helping in sealing the tile structure against dirt and moisture. In a slight variation, the circular cups can be replaced by hex...

second embodiment

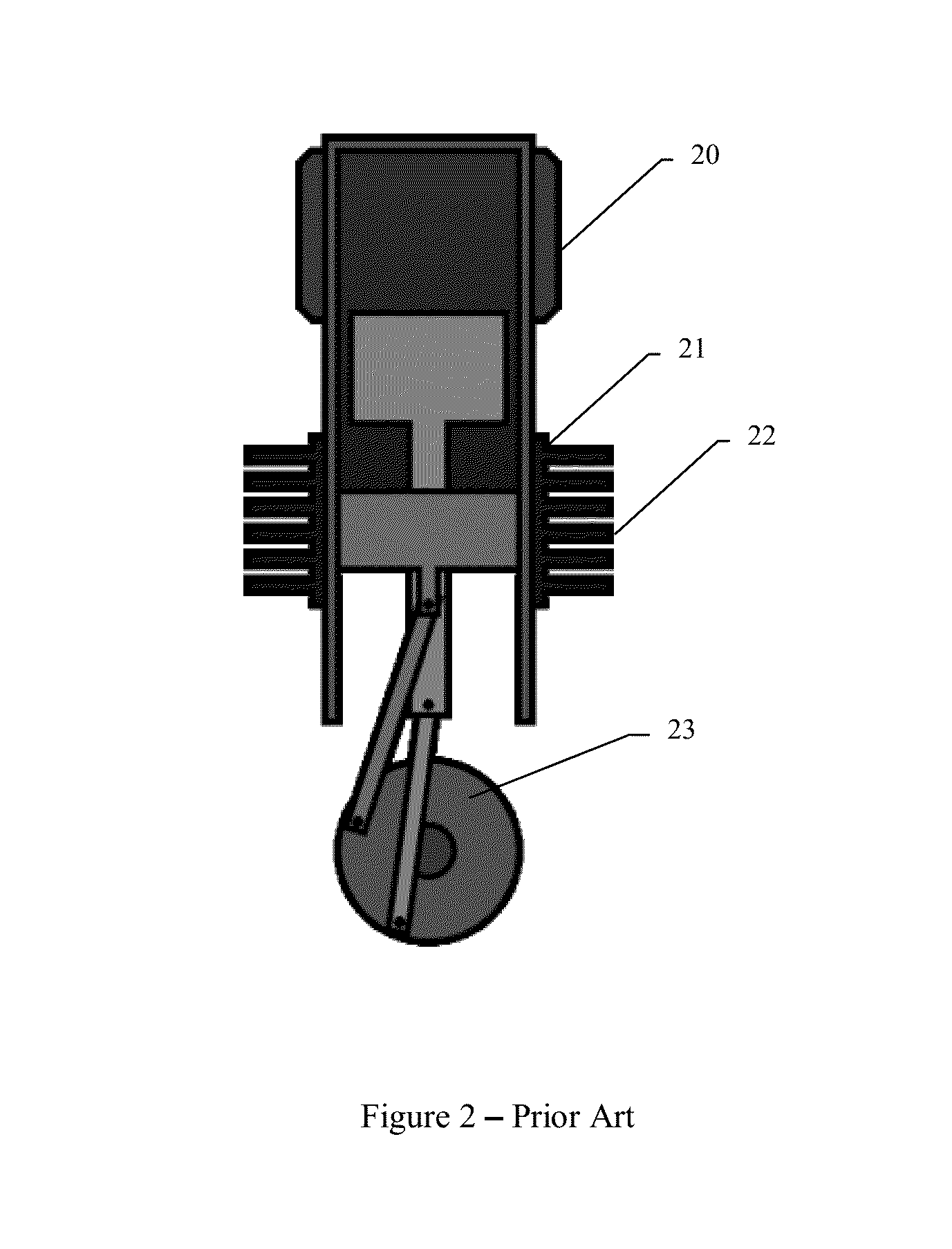

[0290]As shown, the transmission only engages the output wheel during a fraction of the time. FIG. 53 shows a second embodiment, which has 7 arms connected to the pin through flexures [530], and thus 7 walker pads, each performing its advancing motion at a different time, and at least one pad always being engaged to the output wheel. In the drawing, the two pads marked 531 are engaged, whereas the other pads are in different phases of disengagement.

[0291]Other embodiments can use a different number of arms.

third embodiment

[0292]FIG. 54 shows a third embodiment, in which a central hub [540] is mounted on the eccentric crank pin. One of the arms [541], designated the “anchor arm”, prevents the hub from rotating about its own axis, and the other arms can swivel across a small angle around their own pivots [542] as the hub moves with the crank pin. This hub mechanism is common in circular piston engines, such as have been built for piston-driven aviation engines.

[Flower MCPV]

[0293]FIG. 56 shows an embodiment of the invention designed to work at medium concentrations. A number of medium concentration PV receivers [560] (typically made of Silicone, with either air or water cooling, and operating at about 15× concentration) are arranged around the hub [561] in the locations shown, each one corresponding to a single reflective tile [562].

[0294]FIG. 57 shows the optical geometry of the tile. To describe the geometry, the receiver [570] is divided into equal zones (8 in this case). The tile [571], which is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com