Photocurable inkjet printing ink composition, printed matter and molded article

a technology of inkjet printing and composition, which is applied in the direction of inks, instruments, transportation and packaging, etc., can solve the problems of reducing the processability of stretching and bending printed matter, reducing and reducing the hardness of the coating of the photocurable ink, etc., to achieve excellent photocurability, satisfactory the heat resistance of the substrate and the cracking resistance of the ink coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

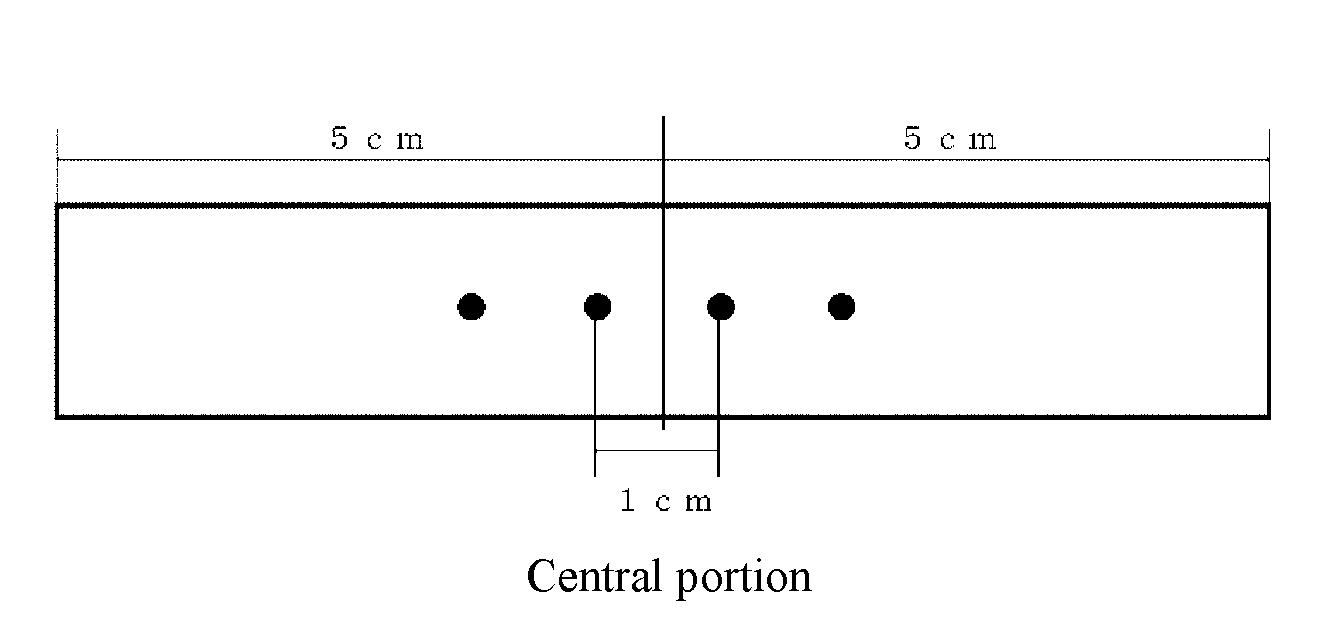

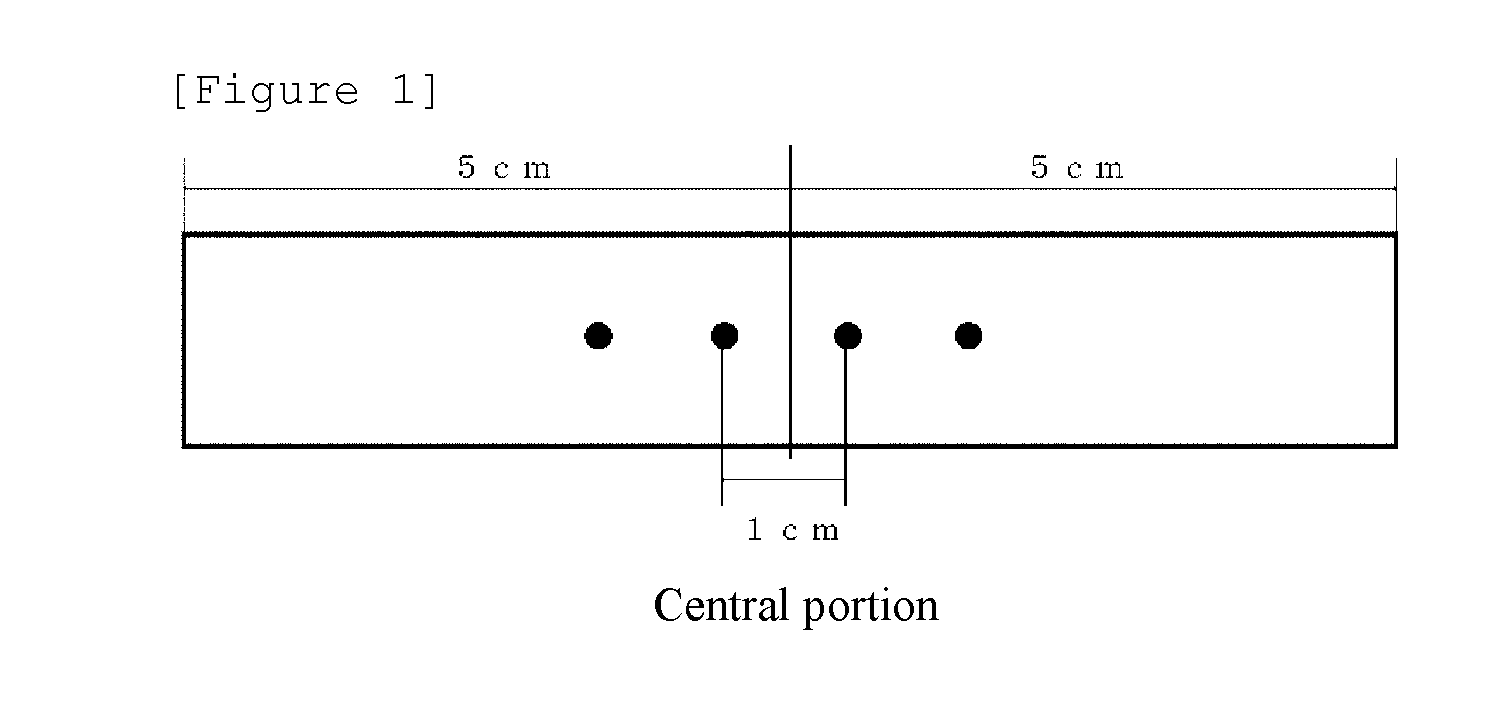

Image

Examples

examples

[0087]Hereinafter, the present invention is described in more detail with reference to Examples; however, the present invention is not limited only to these Examples.

[0088]The materials used in following Examples and Comparative Examples are as follows.

[0089]

[0090]Ajisper PB821 (manufactured by Ajinomoto Co., Inc.)

[0091]

[0092]ACMO: Acryloylmorpholine (manufactured by Kohjin Co., Ltd.)

[0093]V160: Benzyl acrylate (manufactured by Osaka Organic Chemical Ind., Ltd.)

[0094]V190: Ethyl carbitol acrylate (manufactured by Osaka Organic Chemical Ind., Ltd.)

[0095]SR285: Tetrahydrofurfuryl acrylate (manufactured by Sartomer Co., Inc.)

[0096]SR339A: Phenoxyethyl acrylate (manufactured by Sartomer Co., Inc.)

[0097]SR368: Tris(2-hydroxyethyl) isocyanurate triacrylate (manufactured by Sartomer Co., Inc.)

[0098]CD9038: Ethoxylated bisphenol A diacrylate (manufactured by Sartomer Co., Inc.)

[0099]HDDA: 1,6-hexanediol diacrylate (manufactured by Daicel-Cytec Co., Ltd.)

[0100]IBXA: Isobornyl acrylate (manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com