Substrate processing apparatus and substrate processing method using substrate processing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[1] First Embodiment

[0083]A substrate processing apparatus according to the present embodiment is a single-substrate processing apparatus that processes substrates one by one. In the substrate processing apparatus, a high temperature phosphoric acid aqueous solution (H3PO4+H2O) including silicon is supplied as a processing liquid to a substrate on which a silicone oxide film made of silicon oxide (SiO2) and a silicon nitride film made of silicon nitride (Si3N4) are formed. In this case, the phosphoric acid aqueous solution includes silicon, so that an etching rate of the silicone oxide film is reduced. Thus, the silicon nitride film is selectively etched.

[0084]Silicon is present in the phosphoric acid aqueous solution because the silicon nitride film is etched by the phosphoric acid aqueous solution or a liquid concentrate including silicon particles is mixed in the phosphoric acid aqueous solution, for example.

[0085](1) Configuration of Substrate Processing Apparatus

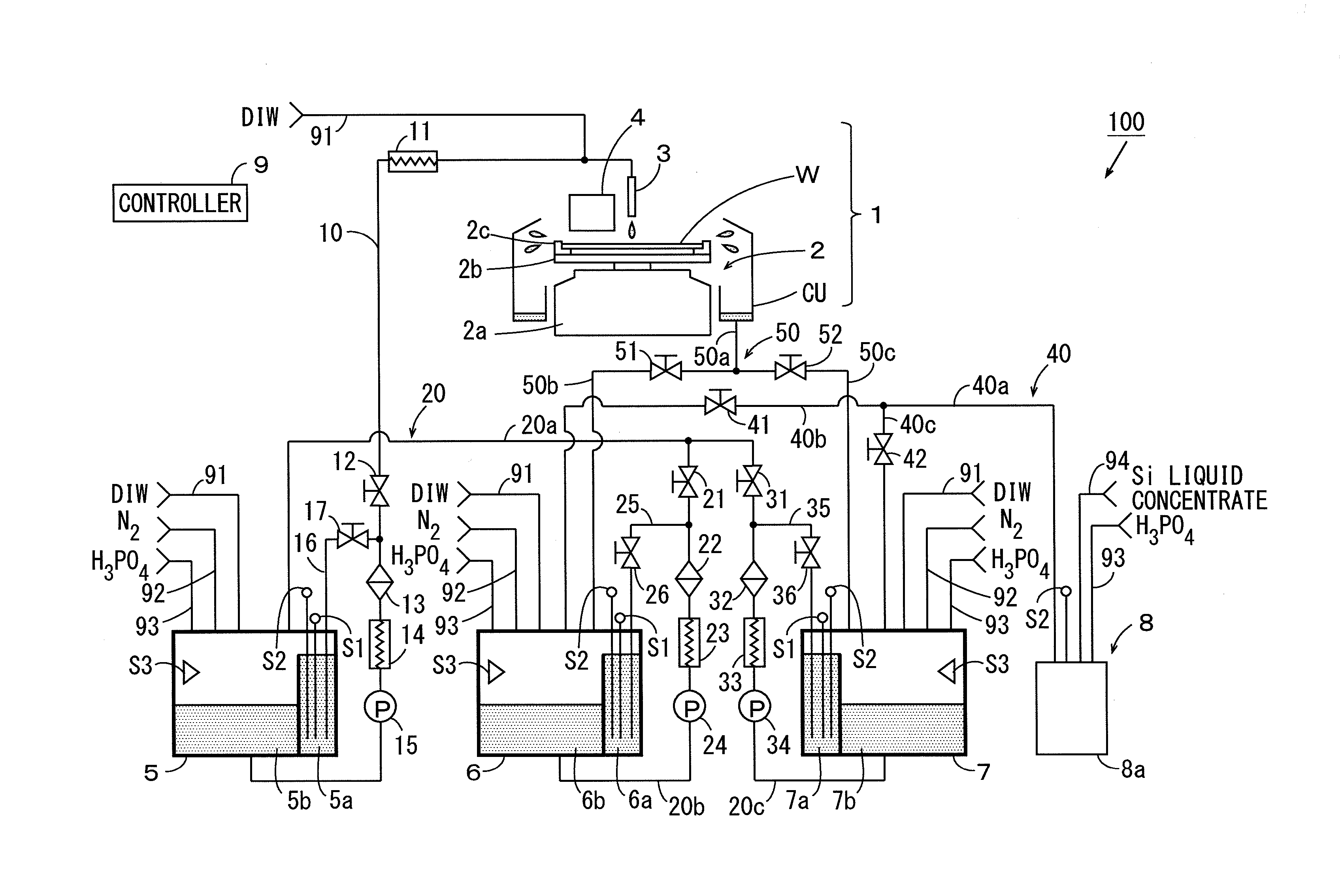

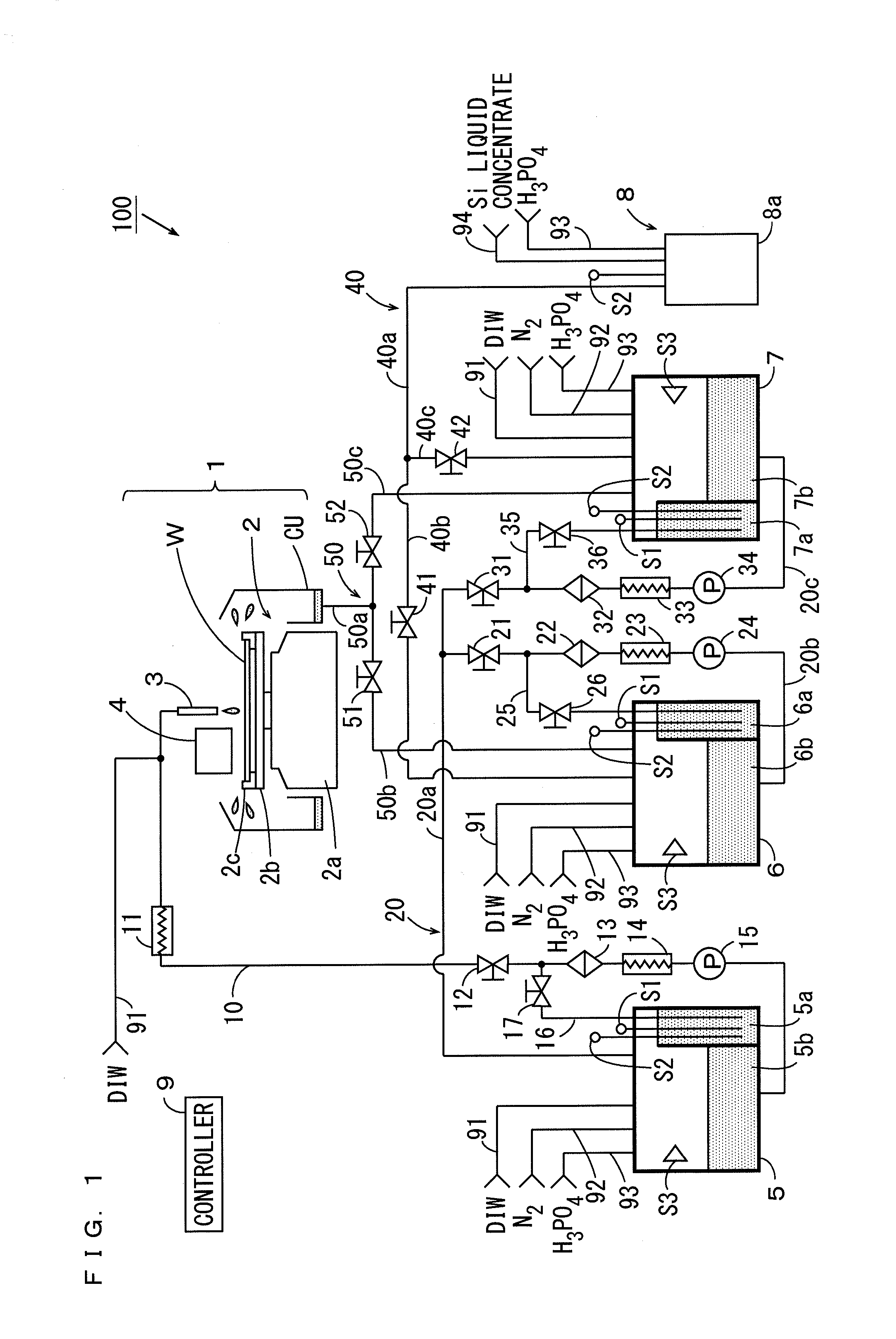

[0086]FIG. 1 is...

second embodiment

[2] Second Embodiment

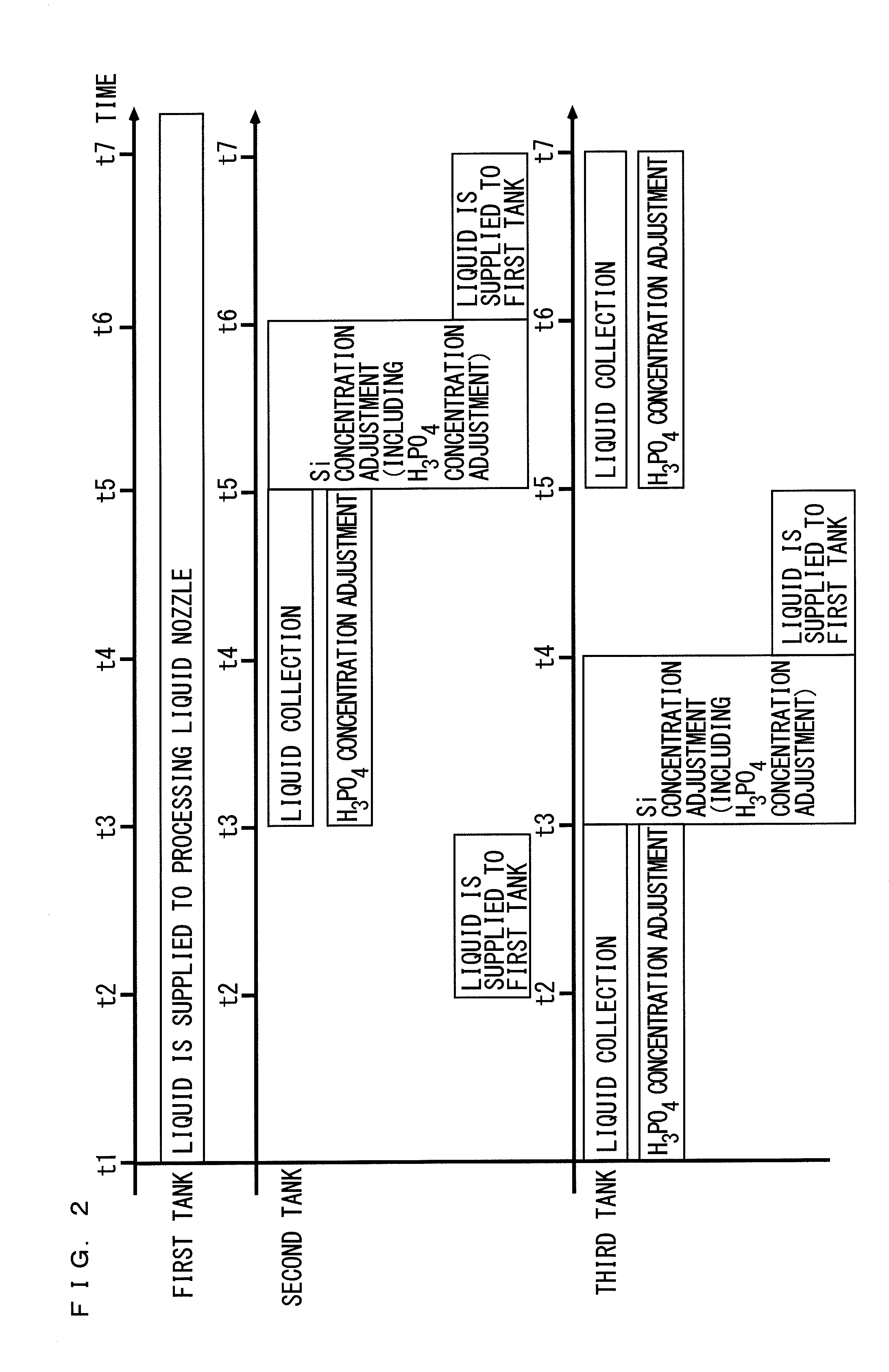

[0177]In the first embodiment, the first tank 5 is only used to supply the phosphoric acid aqueous solution to the processor 1. Further, the second tank 6 and the third tank 7 are used to collect the phosphoric acid aqueous solution and adjust the silicon concentration and phosphoric acid concentration of the phosphoric acid aqueous solution.

[0178]However, the phosphoric acid aqueous solution may be supplied from each of the first tank 5, the second tank 6 and the third tank 7 to the processor 1. Further, each of the first tank 5, the second tank 6 and the third tank 7 may be used to collect the phosphoric acid aqueous solution and adjust the silicon concentration and phosphoric acid concentration of the phosphoric acid aqueous solution.

[0179]FIG. 11 is a schematic view showing the configuration of a substrate processing apparatus according to the second embodiment. The substrate processing apparatus 100 of FIG. 11 has the same configuration as the substrate pro...

third embodiment

[3] Third Embodiment

[0192]A substrate processing apparatus according to the present embodiment is a single-substrate processing apparatus that processes substrates one by one. In the substrate processing apparatus, a high temperature phosphoric acid aqueous solution (H3PO4+H2O) including siloxane is supplied as a high temperature chemical liquid to a substrate on which a silicone oxide film made of silicon oxide (SiO2) and a silicon nitride film made of silicon nitride (Si3N4) are formed. In this case, the phosphoric acid aqueous solution includes siloxane, so that an etching rate of the silicone oxide film is reduced. Thus, the silicon nitride film is selectively etched.

[0193]Siloxane is a collective term for a compound including a Si—O—Si bond of compounds that are made of dioxide, oxygen and hydrogen, and is represented by a general formula (H3SiO—H2SiO)n—SiH3).

[0194]In the following description, a liquid mixture of ammonia water and hydrogen peroxide water is referred to as SC1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com