Chromium-Aluminum Binary Alloy Having Excellent Corrosion Resistance and Method of Manufacturing Thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

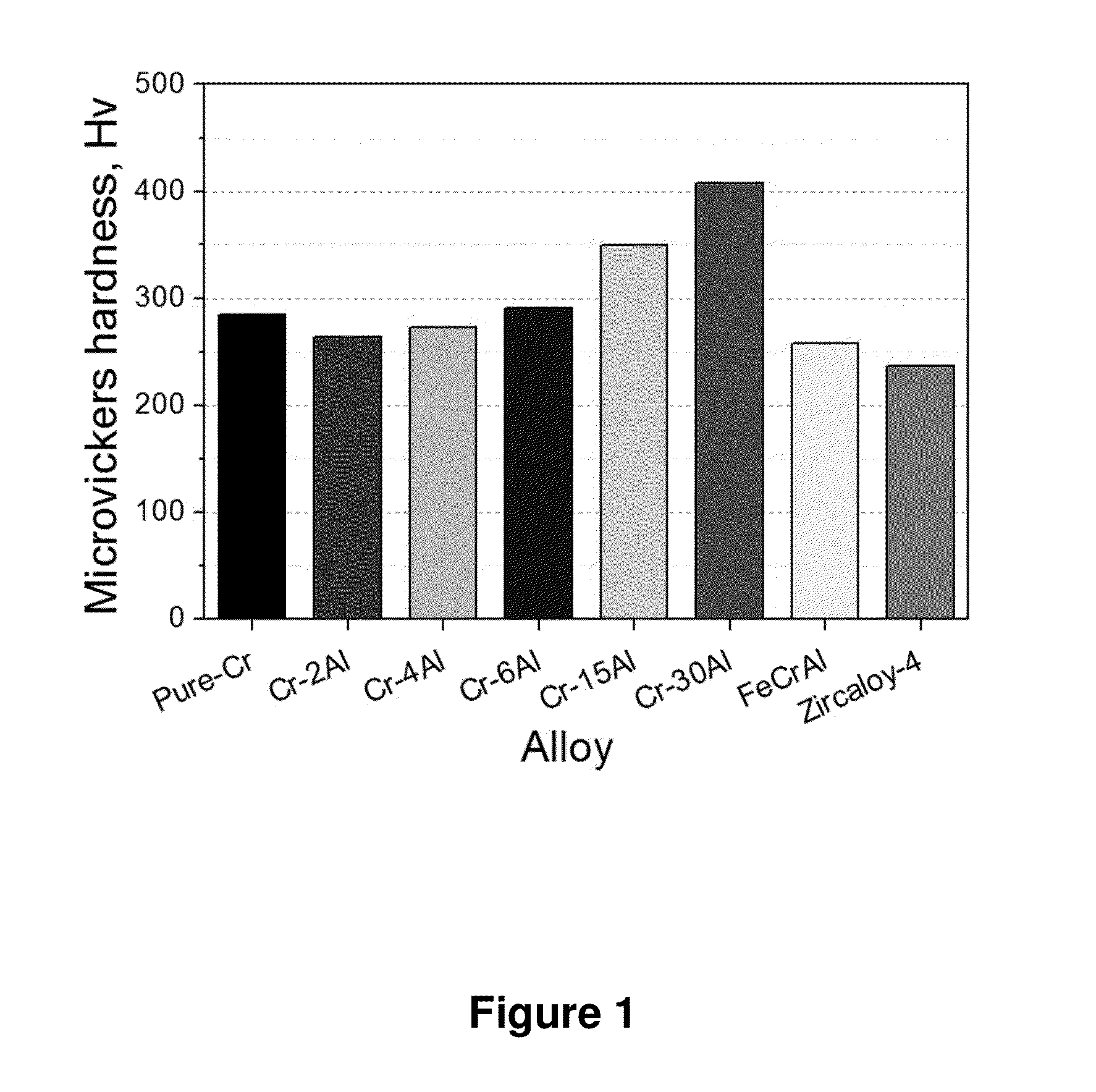

Production of a Cr-2Al Alloy

[0067]Step 1: a melting temperature was set to 1600° C., and through a vacuum arc melting, an alloy having a composition including 2% by weight of aluminum, the balance of chromium and other unavoidable impurities was produced.

[0068]Step 2: the alloy undergone Step 1 was solution treated at 1100° C. for 20 minutes to produce a chromium-aluminum binary alloy.

example 2

Production of a Cr-4Al Alloy

[0069]In step 1 of Example 1, except that the amount of aluminum was changed to 4% by weight, a chromium-aluminum binary alloy was produced by performing the same procedure as Example 1.

example 3

Production of a Cr-6Al Alloy

[0070]In step 1 of Example 1, except that the amount of aluminum was changed to 6% by weight, a chromium-aluminum binary alloy was produced by performing the same procedure as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com