Control device for a hybrid vehicle

a control device and hybrid technology, applied in the direction of electric control, engine starters, machines/engines, etc., can solve the problems of increasing the risk of producing a state in which the brake pedal cannot be significantly depressed and the driver is imparted with a sense of unease, and achieve the effect of regenerative energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

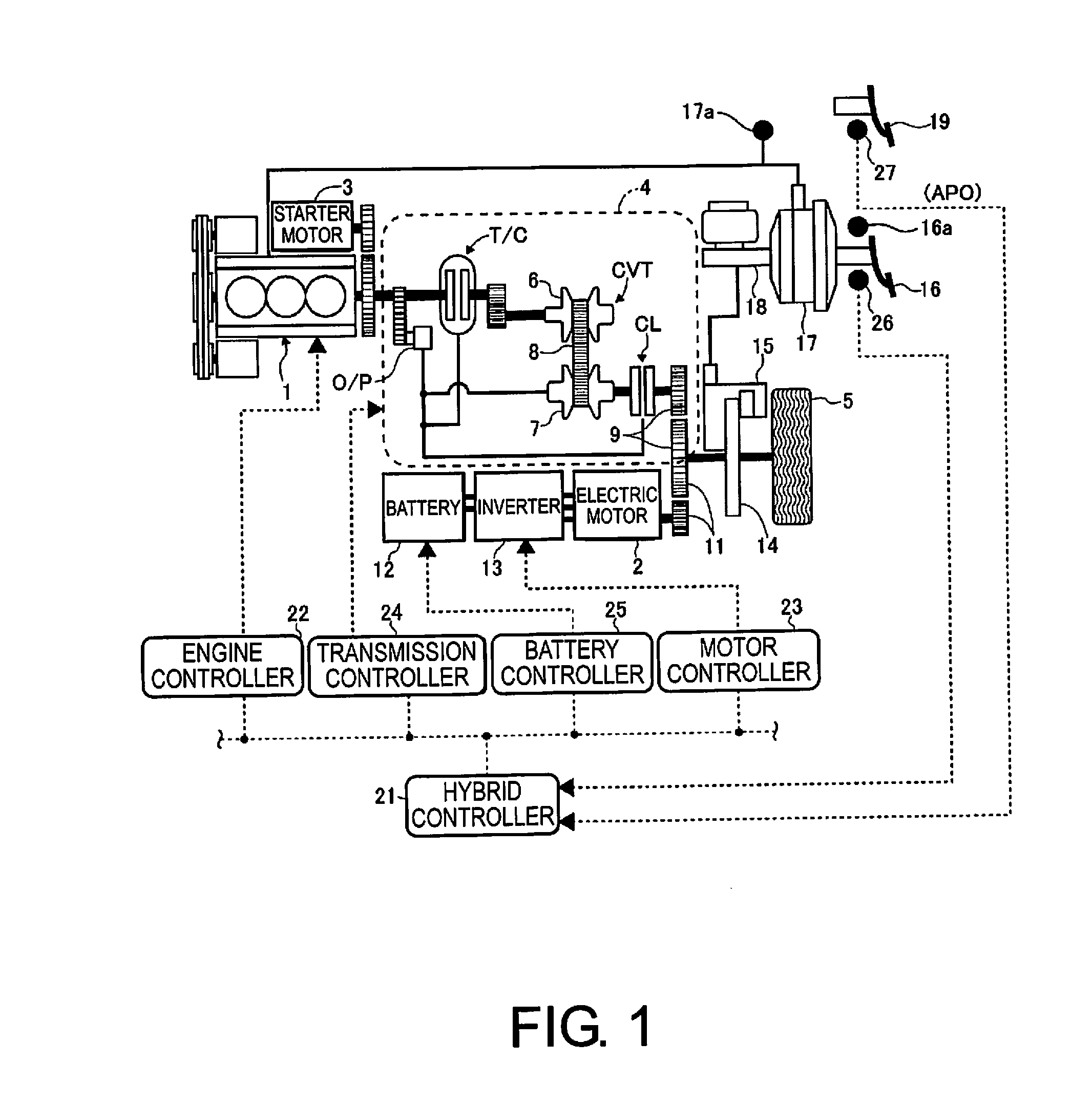

[0019]FIG. 1 is a schematic system diagram showing a driving system and an overall control system of a hybrid vehicle with a control device according to a first embodiment. The hybrid vehicle in FIG. 1 has an engine 1 and an electric motor 2 mounted thereon as drive sources, and the engine 1 is started by a starter motor 3. The engine 1 is drivingly coupled to a drive wheel 5 by a V-belt-type continuously variable transmission 4 so as to be capable of being decoupled as appropriate. An overview of the V-belt-type continuously variable transmission 4 will now be given below.

[0020]The V-belt-type continuously variable transmission 4 is a continuously variable transmission mechanism CVT comprising a primary pulley 6, a secondary pulley 7, and a V-belt 8 extended between the pulleys 6, 7. The primary pulley 6 is coupled to a crank shaft of the engine 1 via a torque converter T / C having a lock-up clutch. The secondary pulley 7 is coupled to the drive wheel 5 via a clutch CL and a final g...

second embodiment

[0075]A second embodiment will now be described. The basic configuration is the same as that of the first embodiment; therefore, a description will be given with regards to the differences. In the first embodiment, when the EV deceleration regeneration mode is selected, the engine 1 is put in an idling state. In contrast, in the second embodiment, as a brake request made by the driver, the negative pressure of the negative pressure-type brake booster 17 is detected by the negative pressure sensor 17a, and the presence of a predetermined value (negative pressure necessary for braking) is determined. If the predetermined value is not available, a negative pressure request is outputted, and the operation state of the engine 1 is maintained. If the negative pressure is available, the negative pressure request is stopped, i.e., the fuel-cut recovery control is prohibited from taking place. The negative pressure necessary for braking refers to, e.g., a value at which a rapid deceleration ...

third embodiment

[0082]A third embodiment will now be described. The basic configuration is the same as that of the second embodiment; therefore, a description will be given with regards to the differences. In the third embodiment, when the operation of the engine 1 is stopped as with the second embodiment and the braking force requested by the driver subsequently becomes equal to or greater than a predetermined value, the clutch CL is engaged to ensure negative pressure is obtained. In the third embodiment, with regards to the required braking force value, a determination is made on the basis of whether or not the stroke amount detected by the stroke sensor 16a is equal to or greater than a predetermined value. However, the above is not provided by way of limitation; any configuration capable of detecting the brake request made by the driver, such as one for detecting, e.g., the master cylinder pressure or the depression force, is also possible.

[0083]FIG. 5 is a time chart showing the control proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com