Real-time wireless dynamic tire pressure sensor and energy harvesting system

a dynamic tire and sensor technology, applied in the direction of instruments, pedestrian/occupant safety arrangements, vehicular safety arrangements, etc., can solve the problems of ambient noise preventing detection, and achieve the effects of increasing output power density, constant and steady power, and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

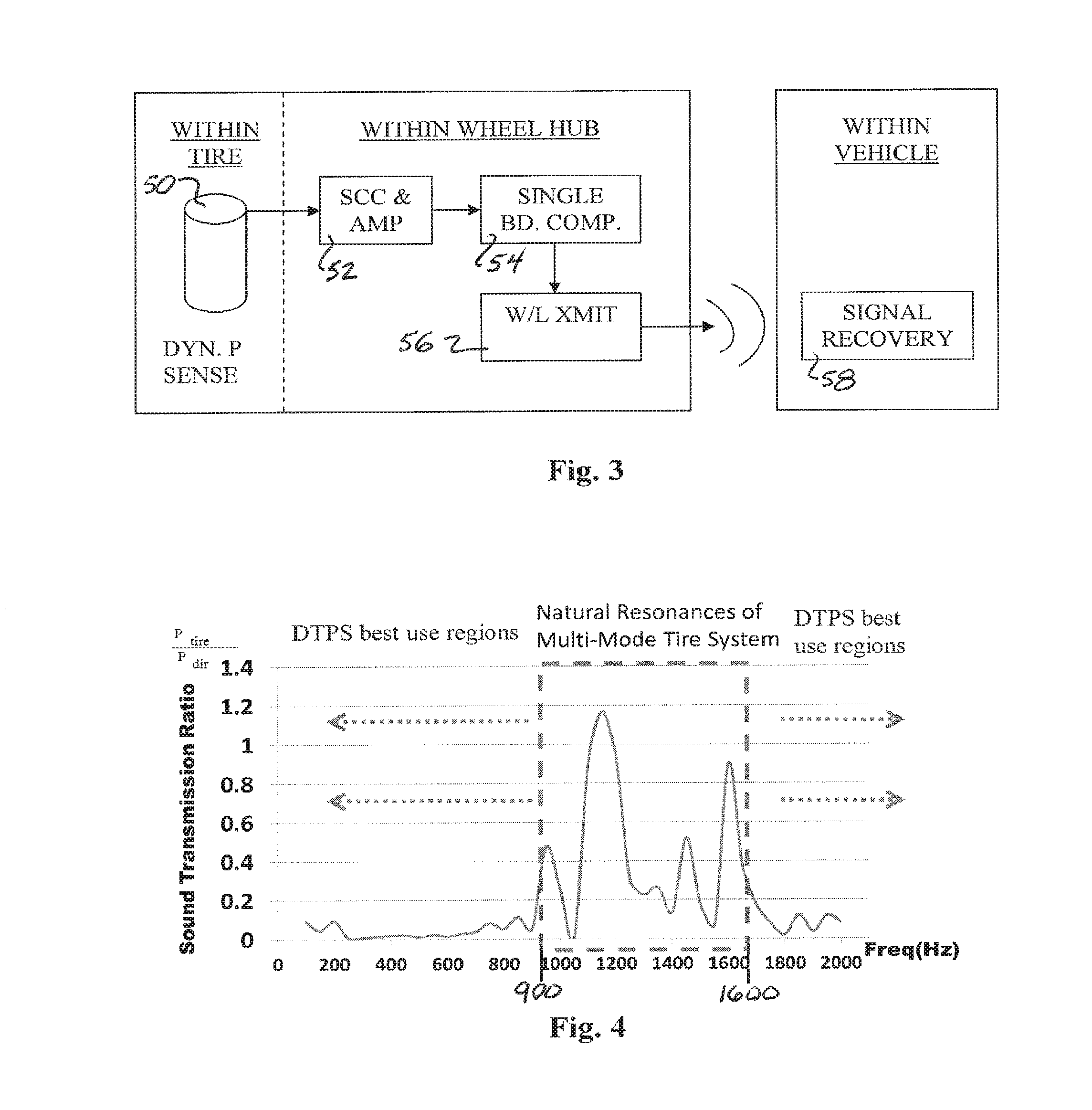

[0046]Different acoustic and surface waves are generated at specific frequencies and amplitudes while a vehicle is traveling on varying road surfaces. These waves depend in part on the material properties of the road structure. The atmospheric acoustic field between the vehicle chassis and the road is also complex. Acoustic sources include aerodynamic effects, vehicle body vibration, ground vibration, direct radiation from the tire-road interface, and ambient noise due to other vehicles or acoustic sources.

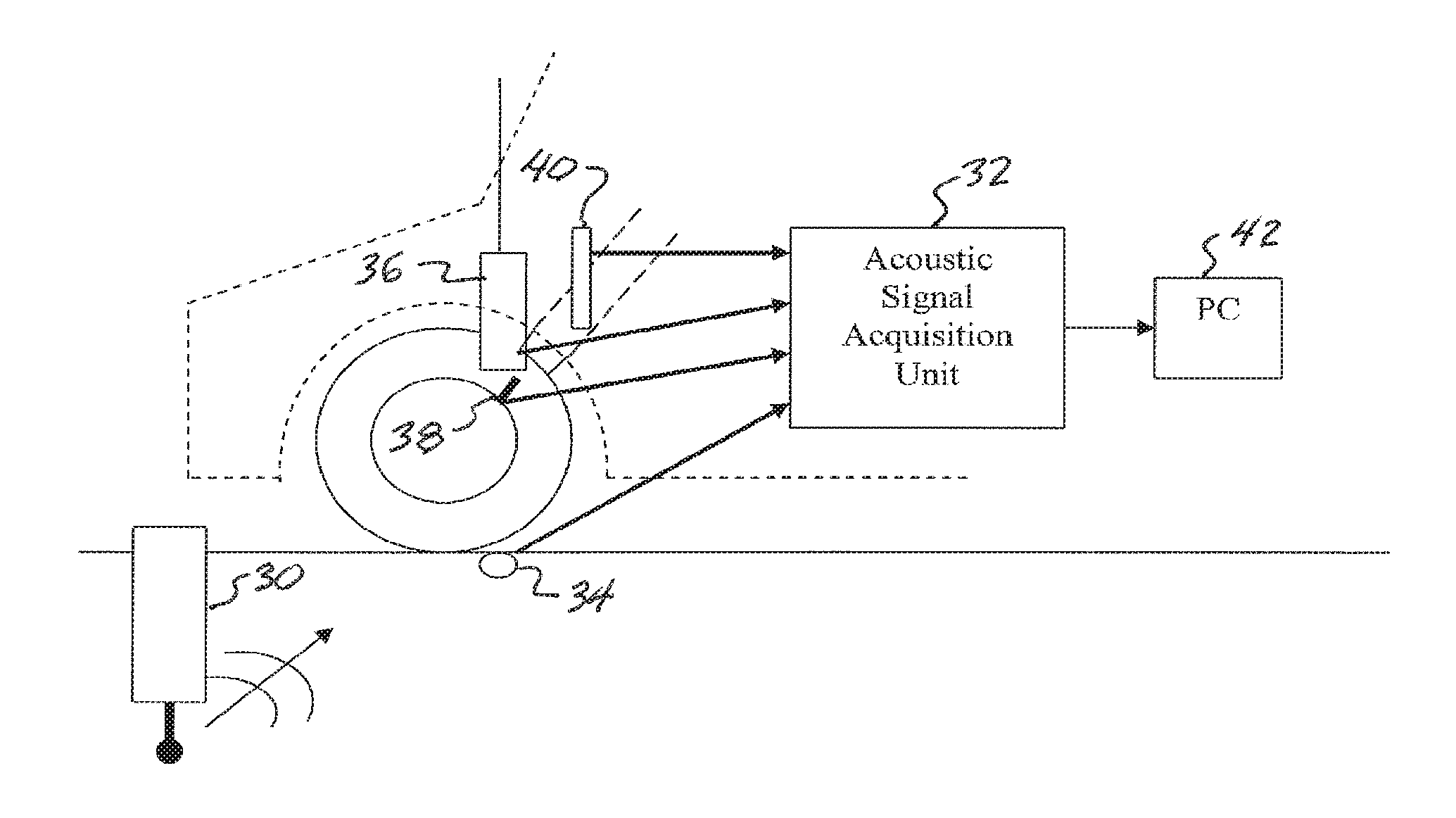

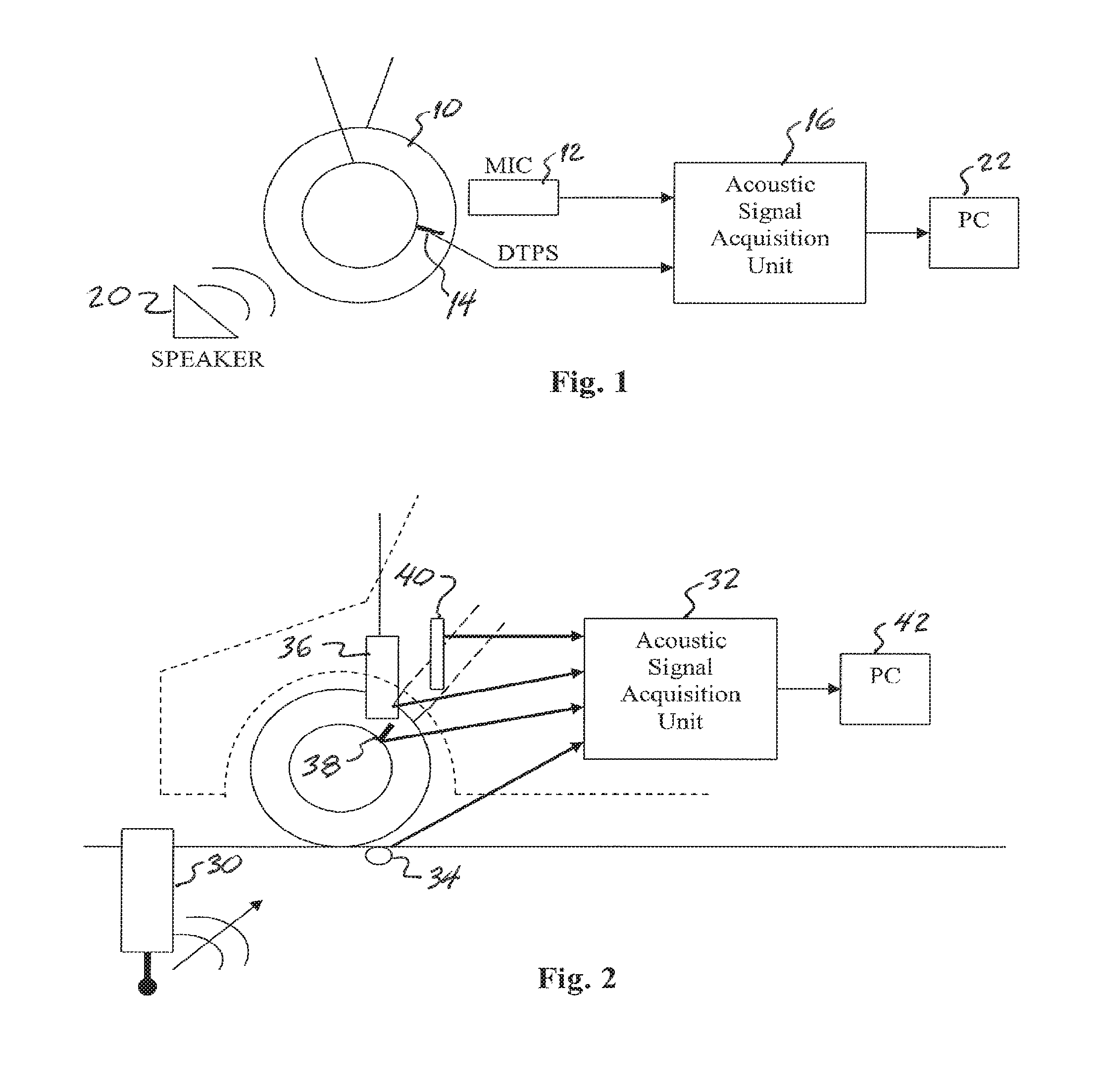

[0047]Specifically, there are five distinct wave types that can be coupled to form acoustic waves within a subject vehicle tire due to complex interactions of the tire with the road surface. These different effects on the tire are: 1) direct surface wave from other tires or vehicles passing on the roadway nearby; 2) the acoustic wave from the interaction of the subject tire rolling on the roadway; 3) tire vibration (elastic) from, for example, axle vibration, or own tire excitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency range | aaaaa | aaaaa |

| frequency range | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com