Semiconductor device and method of manufacturing semiconductor device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

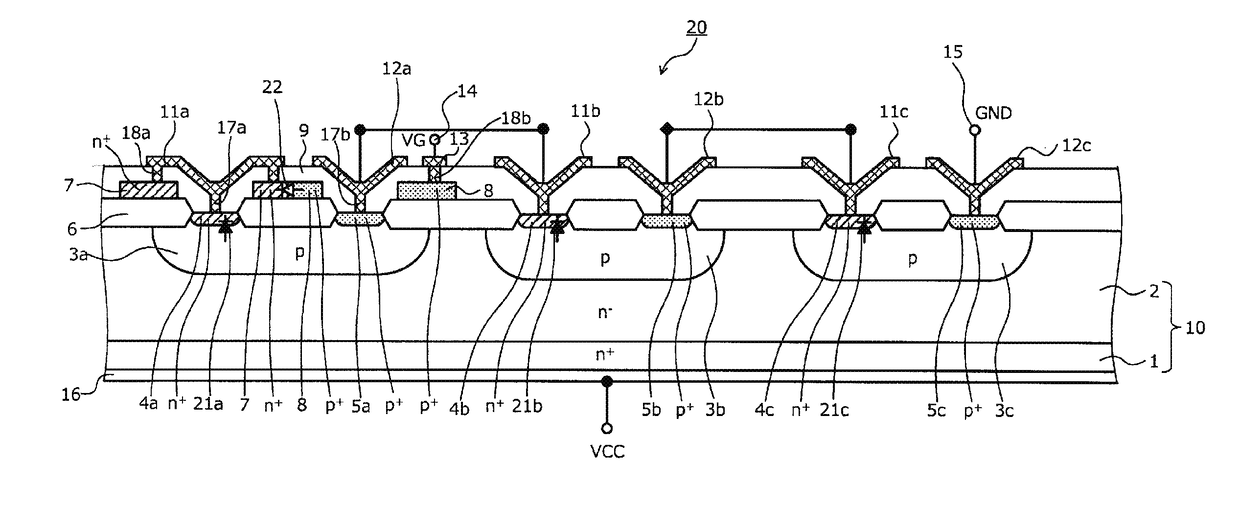

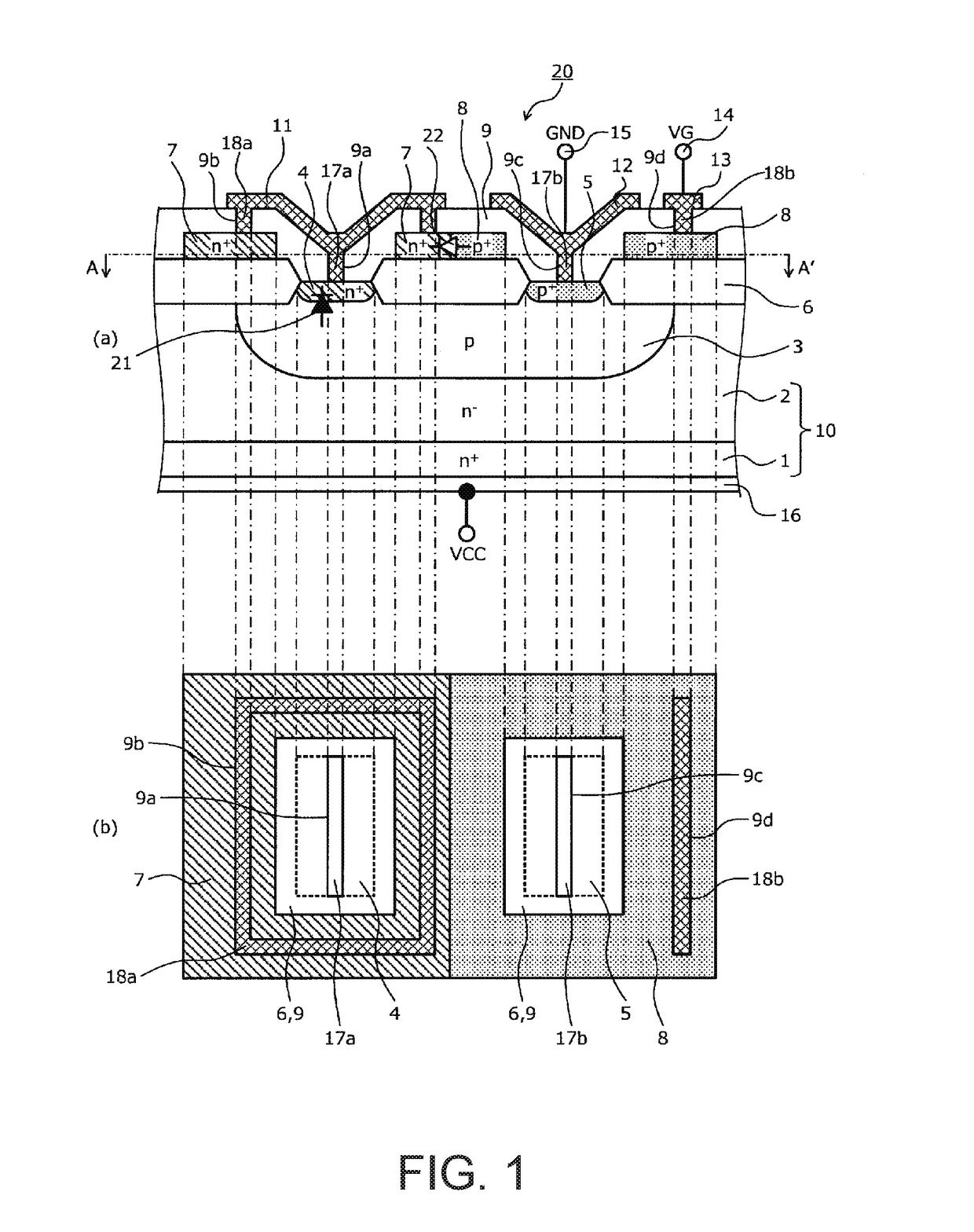

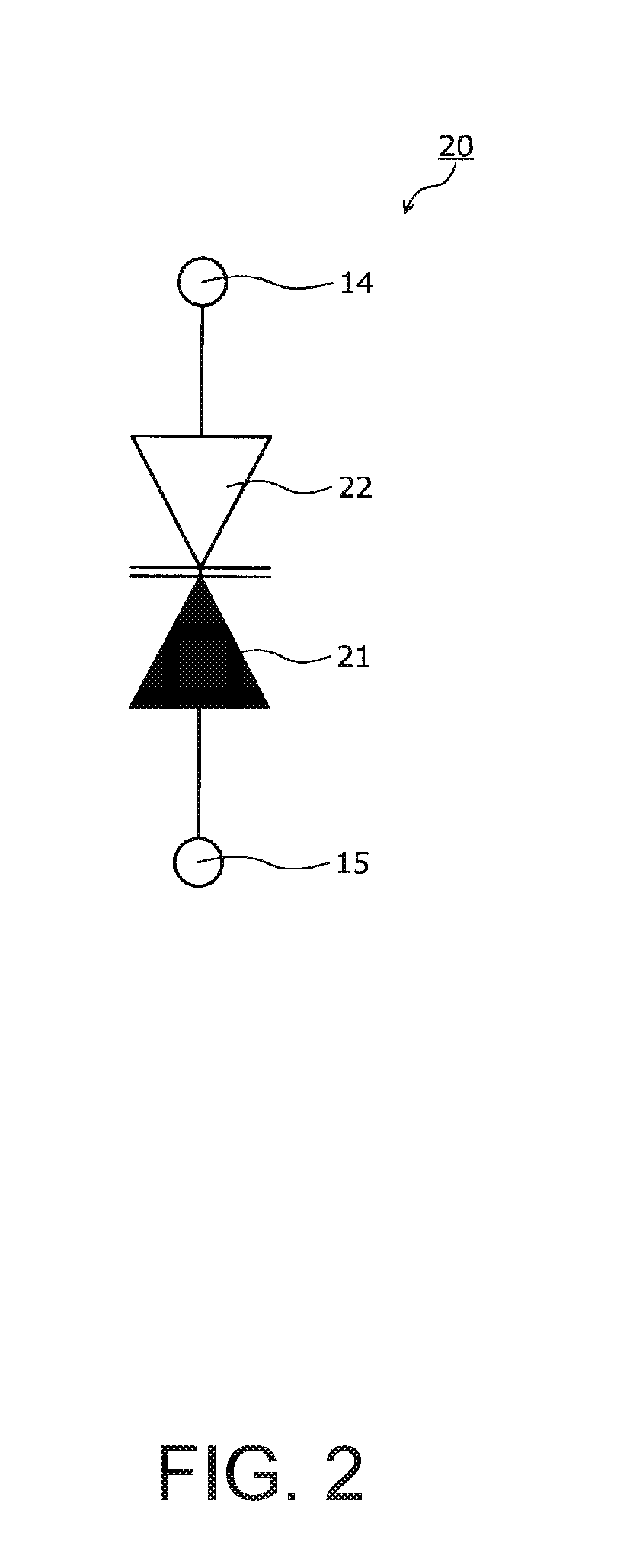

[0064]A semiconductor device according to Embodiment 1 includes an n-channel MOSFET and a lateral protection device for protecting (providing gate protection for) a gate insulating film of the n-channel MOSFET, and the n-channel MOSFET and the lateral protection device are both formed on the same semiconductor substrate (semiconductor chip). FIG. 1 illustrates the main components of the structure of the semiconductor device according to Embodiment 1. FIG. 1 only depicts a lateral protection device 20 of the semiconductor device according to Embodiment 1, and other components that are formed in the same semiconductor substrate as the lateral protection device 20 are not illustrated in the figure. FIG. 1(a) illustrates the cross-sectional structure of the lateral protection device 20, and FIG. 1(b) is a plan view of a section taken along line A-A′ in FIG. 1(a). FIG. 2 is a circuit diagram illustrating an equivalent circuit for the configuration illustrated in FIG. 1.

[0065]As illustrat...

embodiment 2

[0093]Next, the structure of a semiconductor device according to Embodiment 2 will be described. FIG. 7 illustrates the main components of the structure of the semiconductor device according to Embodiment 2. FIG. 7 only depicts a lateral protection device 80 of the semiconductor device according to Embodiment 2, and other components are not illustrated in the figure. The planar layout of the lateral protection device 80 as taken along line B-B′ in FIG. 7 is the same as the planar layout of the lateral protection device according to Embodiment 1 (see FIG. 1(b)) except in that the conductivity type (p-type or n-type) of each region is inverted. FIG. 8 is a circuit diagram illustrating an equivalent circuit for the configuration illustrated in FIG. 7. The semiconductor device according to Embodiment 2 is different than the semiconductor device according to Embodiment 1 in that the conductivity types (p-type or n-type) of the semiconductor substrate, the semiconductor regions (or semico...

embodiment 3

[0108]A semiconductor device according to Embodiment 3 includes the lateral protection device 30 of Embodiment 1 (see FIG. 6B) as well as other components that are arranged on the same semiconductor substrate 10. FIG. 10 illustrates the structure of the semiconductor device according to Embodiment 3. FIG. 10 illustrates an example of a high-side power IC for use in a vehicle that includes an output stage vertical MOSFET 210, a lateral CMOS which is a circuit device for a control circuit for the vertical MOSFET 210, and the lateral protection device 30, which are all arranged on the same semiconductor substrate 10. The power IC also includes a lateral p-channel MOSFET and a lateral n-channel MOSFET connected together complementarily to form the lateral CMOS. However, FIG. 10 only depicts the lateral n-channel MOSFET 220. The lateral protection device 30 protects a gate electrode 225 of the lateral n-channel MOSFET 220.

[0109]More specifically, the semiconductor substrate 10 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com