Casting green sand mold for forming cast steel article and its production method, and method for producing cast steel article using such green sand mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first example

(A) FIRST EXAMPLE

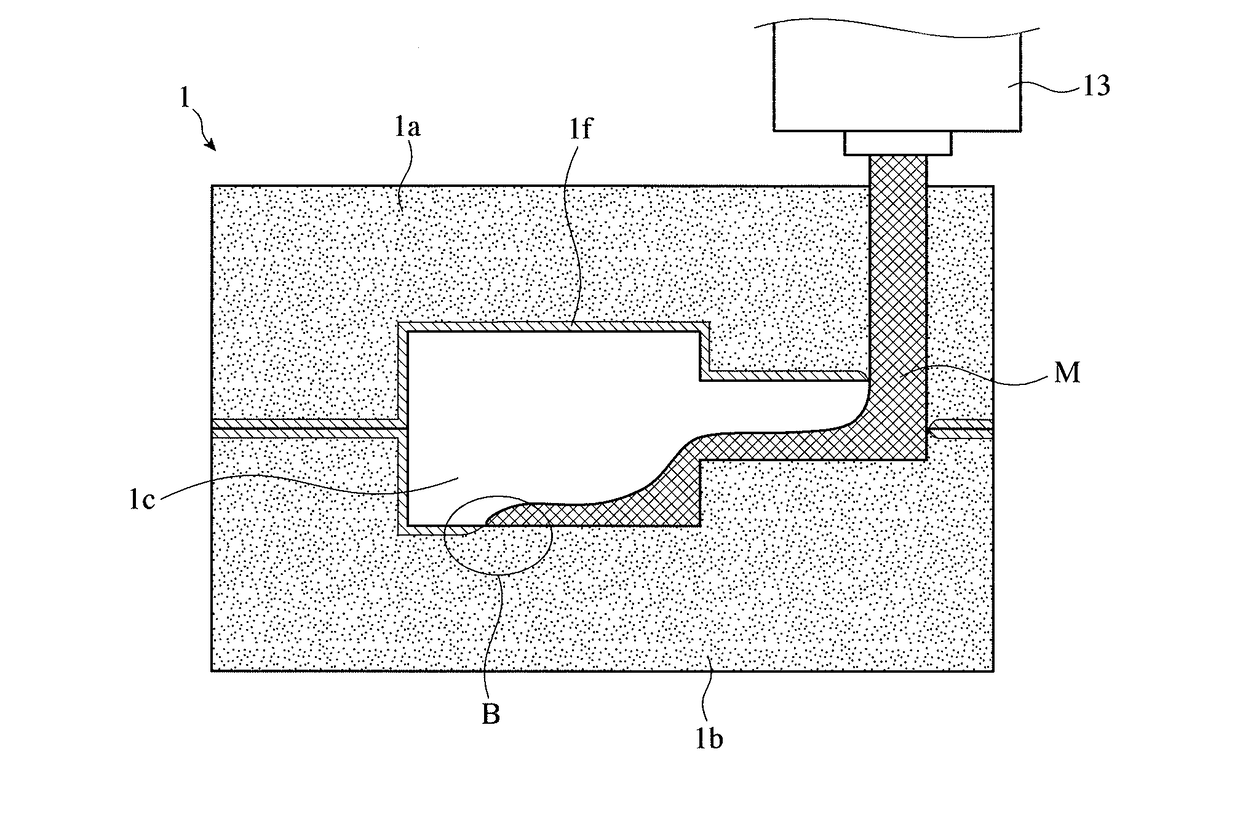

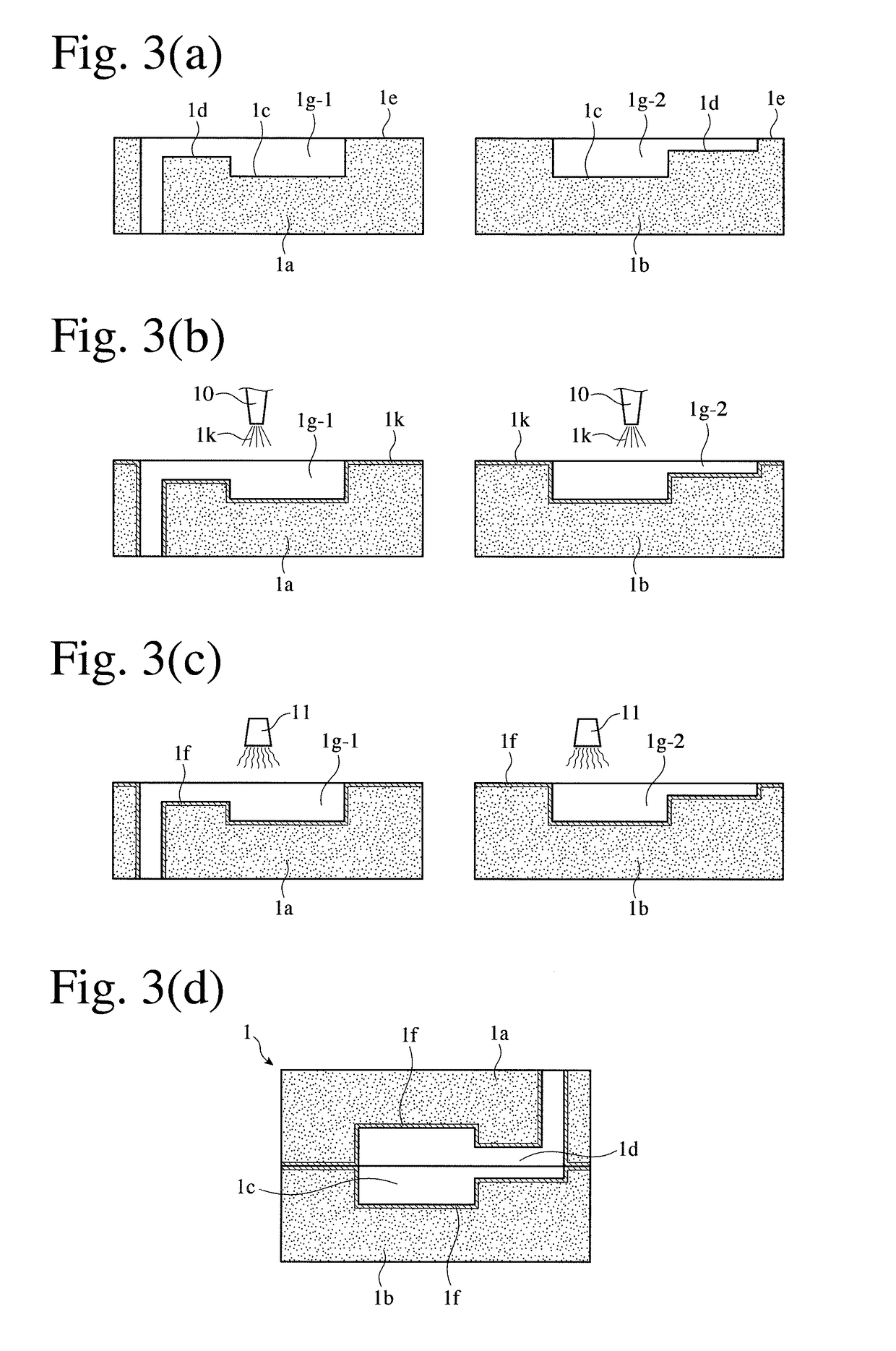

[0059](1) Mold-Forming Step

[0060]As shown in FIG. 3(a), casting sand obtained by blending predetermined amounts of sand, a binder, a carbonaceous component and water is formed into an upper mold part 1a and a lower mold part 1b having recesses 1g-1, 1g-2 for an article-forming cavity 1c and a runner 1d. To provide a green sand mold with enough strength with easy forming, the amounts of a binder and water added to the casting sand are generally 5-12 parts by mass of a binder and 1-5 parts by mass of water per 100 parts by mass of sand, though properly adjustable depending on the characteristics of a green sand mold.

[0061]The upper mold part 1a and the lower mold part 1b are formed, for example, by charging the casting sand into each flask in which a casting model for an article-forming cavity, a runner, etc. is placed, compressing the casting sand by a jolt squeeze method, etc., and finally removing the casting model.

[0062](2) Coating Step

[0063]In the upper mold part...

second example

(B) SECOND EXAMPLE

[0069]The second example of the production methods of a green sand mold 1 is explained referring to FIG. 4. In FIG. 4, the same reference numerals are assigned to the same portions as in FIG. 3, with their detailed explanations omitted. The second example of the production methods of a green sand mold 1 is the same as the first example, except for having the first and second hardening steps shown in FIGS. 4(c) and 4(e).

[0070]In the second example, the recesses 1g-1, 1g-2 of the upper mold part 1a and the lower mold part 1b formed in the mold-forming step shown in FIG. 4(a) are coated with a coating solution 1k in the coating step shown in FIG. 4(b), and hot air is supplied from a blower 11 to heat the coating solution 1k, thereby forming a semi-hardened layer 1L, in the first hardening step shown in FIG. 4(c). After the upper mold part 1a and the lower mold part 1b each provided with a semi-hardened layer 1L are combined in the molds-combining step shown in FIG. 4(...

example 1

[0076](1) Sand-Preparing Step

[0077]100 parts by mass of silica sand was mixed with 8.1 parts by mass of bentonite, 3.0 parts by mass of water, and 3 parts by mass of carbon powder, to prepare casting sand.

[0078](2) Mold-Forming Step

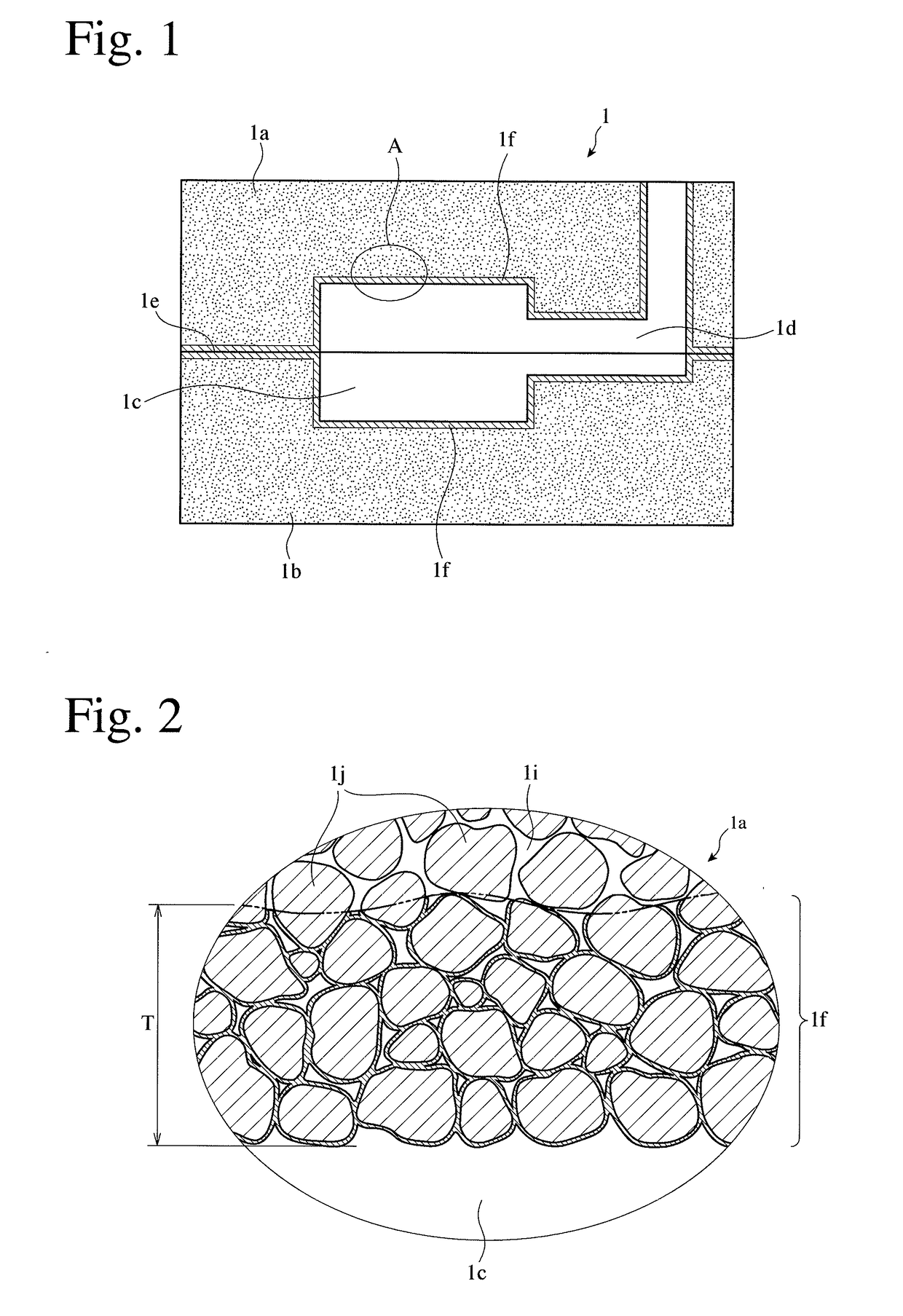

[0079]Casting sand was charged into flasks in each of which a casting design model was set, and compressed by a jolt-squeeze method to form upper and lower mold parts. Measurement at five points by a self-hardening mold hardness tester (NK-009 available from Nakayama Co., Ltd.) revealed that the average hardness of each recess of the upper and lower mold parts was 20. FIG. 8(a) is a SEM photograph (100 times) showing a recess surface of the formed green sand mold. As is clear from FIG. 8(a), there were a lot of voids between binder-covered sand particles.

[0080](3) Coating Step

[0081]As shown in Table 2, a coating solution (viscosity: 20 mPa·s) comprising 40% by mass of a phenol resin and 60% by mass of ethanol was applied to the recesses and parting surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com