Propellant compositions comprising nitramine oxidants

a technology of nitramine oxidants and propellant compositions, which is applied in the direction of nitrocellulose explosive compositions, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problems of irritating eyes, skin, and eye irritation, and achieves stable interior ballistics characteristics, improve the characteristics of extrudates, and improve physical compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

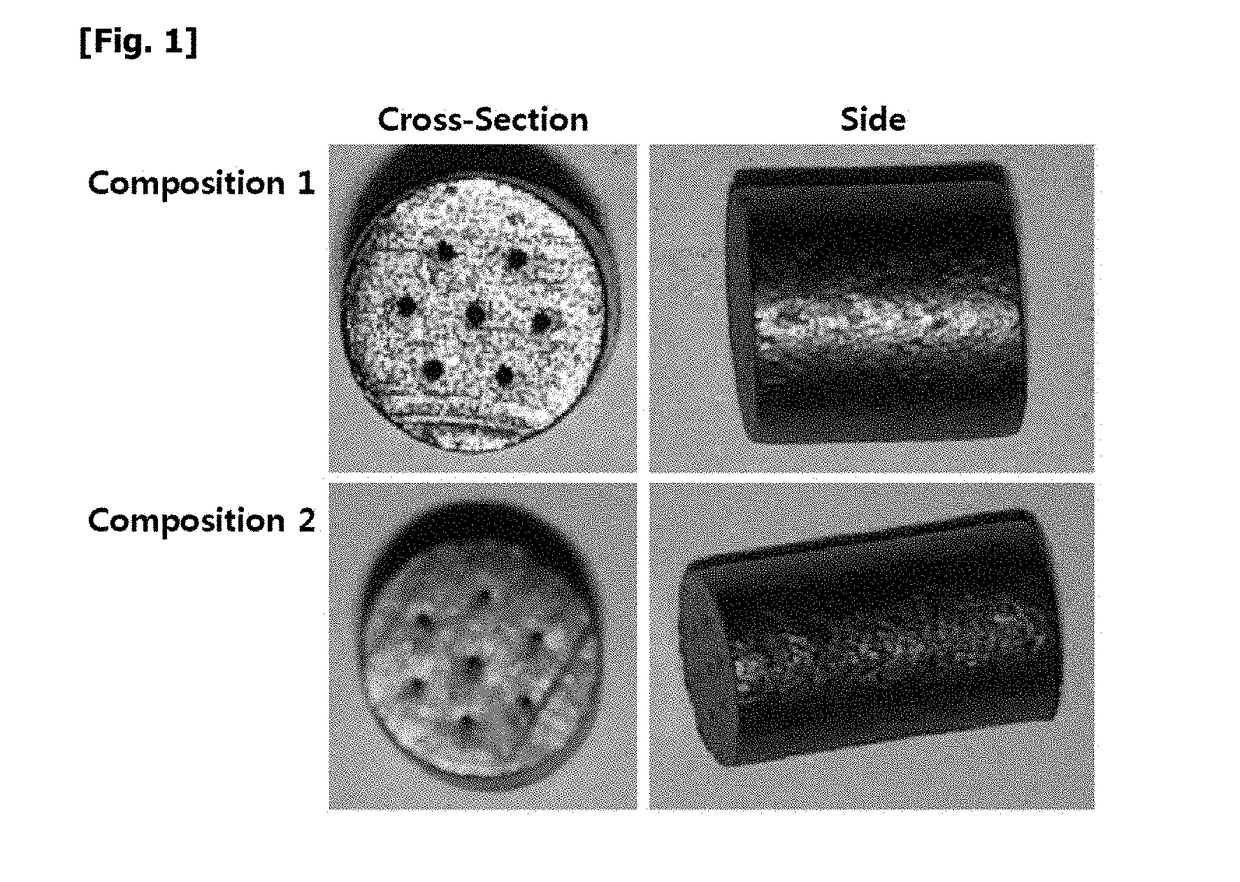

1. Preparation of Propellant Compositions

[0038]As solvents, Acetone (Daejung Chemical & Metals Co., Ltd., Korea), ethyl acetate (Daejung Chemical & Metals Co., Ltd., Korea) and diethyl ether (Daejung Chemical & Metals Co., Ltd., Korea) were put into a Sigma Blade Mixer (Fine Machinery Ind. Co., Ltd., Korea), and then nitrocellulose (Hanwha Corporation, Korea) was added thereto and dissolved. After complete dissolution, a mixture containing a nitramine solid oxidant, a plasticizer and a stabilizer was added into the mixer and sufficiently mixed. The solvent was evaporated until the mixture had a suitable viscosity, and then the mixture was tightly sealed to prevent additional evaporation of the solvent. The kneaded / obtained mixture was put into a RAM PRESS (Boo Young Precision Tool Co., Ltd., Korea) equipped with a propellant mold, and was extruded by adding pressure thereto. After the extrudate was cut into a predetermined size to make a grain form, it was dried at normal temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com