Method for doping semiconductors

a semiconductor and semiconductor technology, applied in the field of doping semiconductors, can solve the problems of not having major industrial importance, not using the etching technique in industrial practice, and not completely suppressing the diffusion on the back, so as to improve the light yield, improve the effect of efficiency and improve the properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

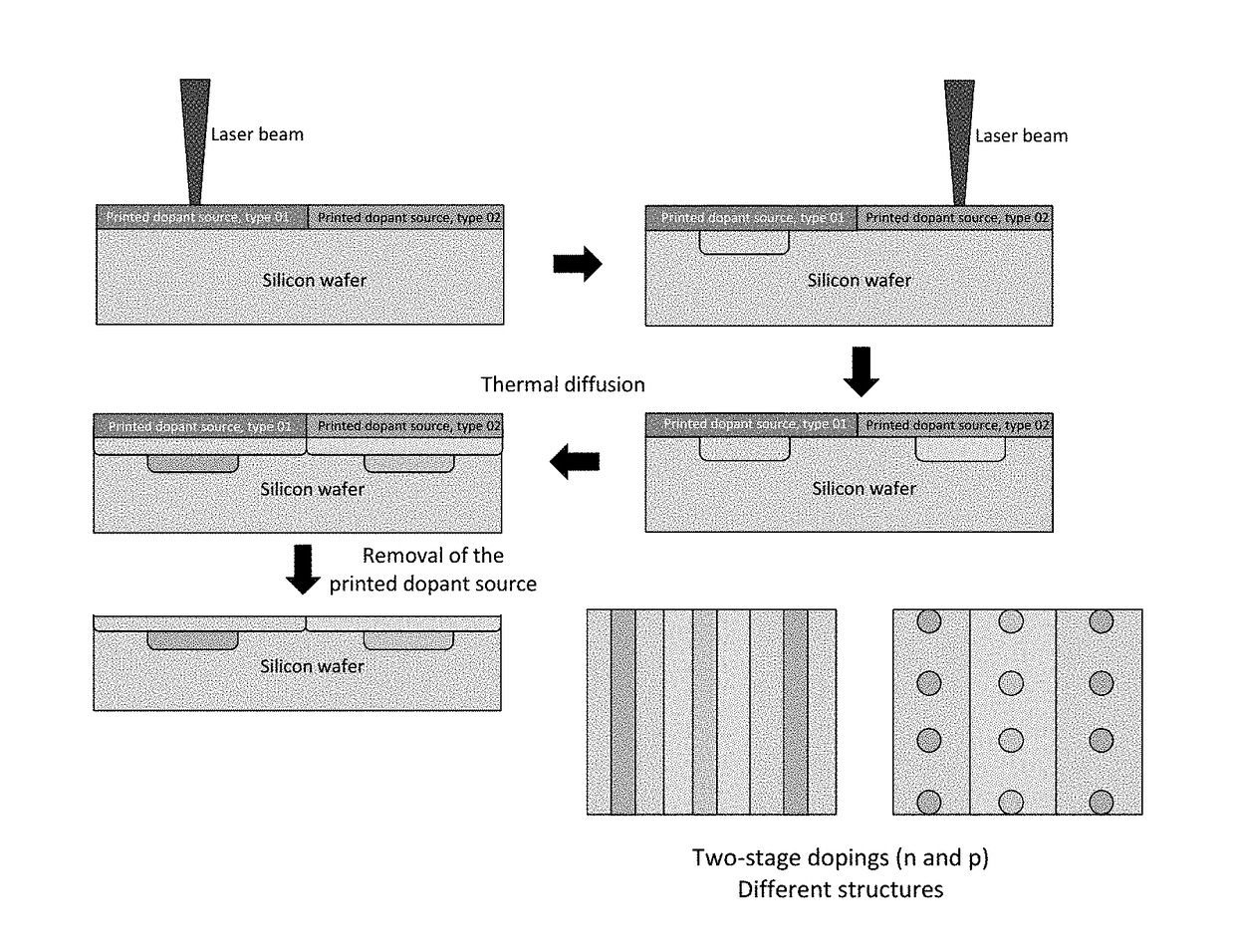

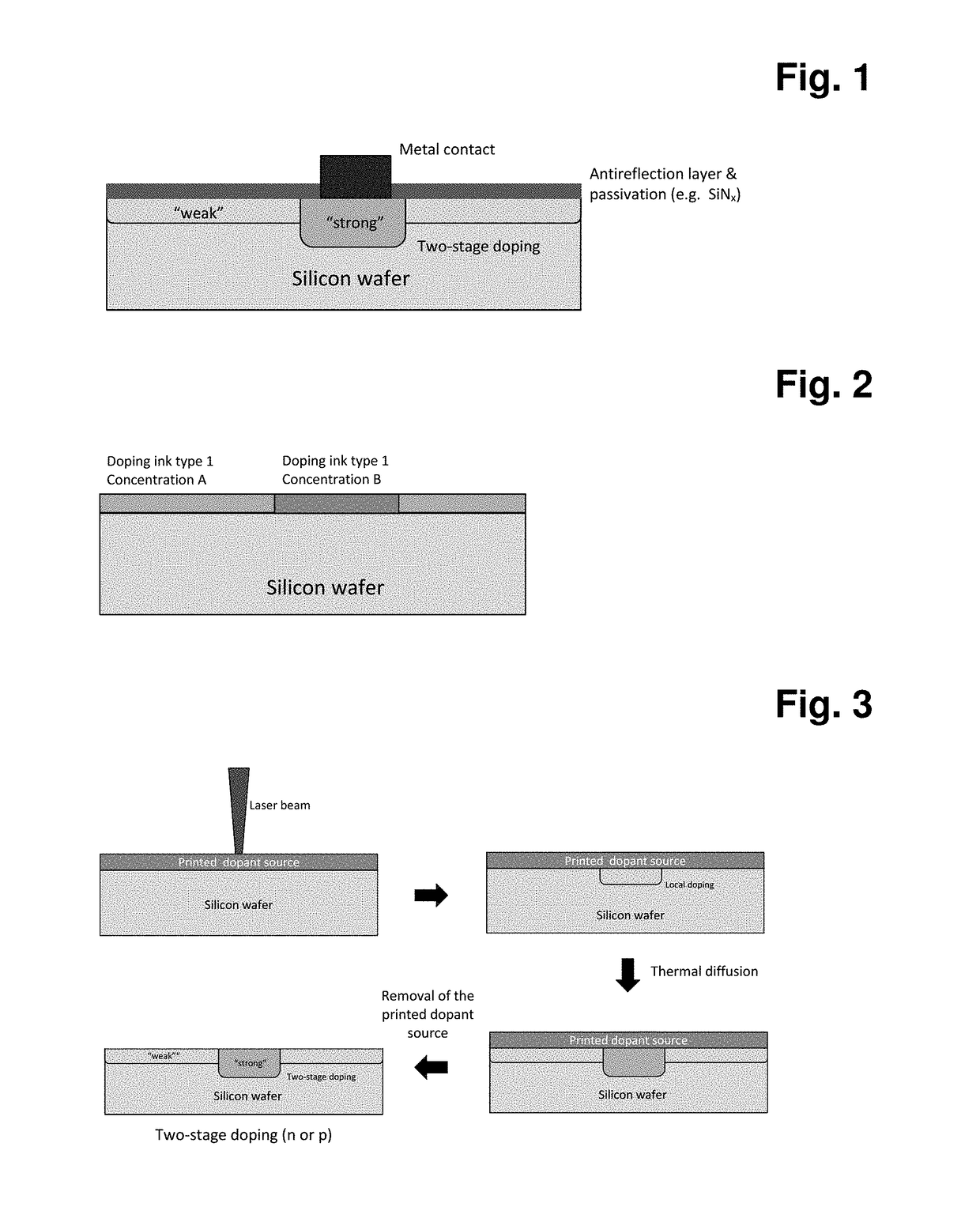

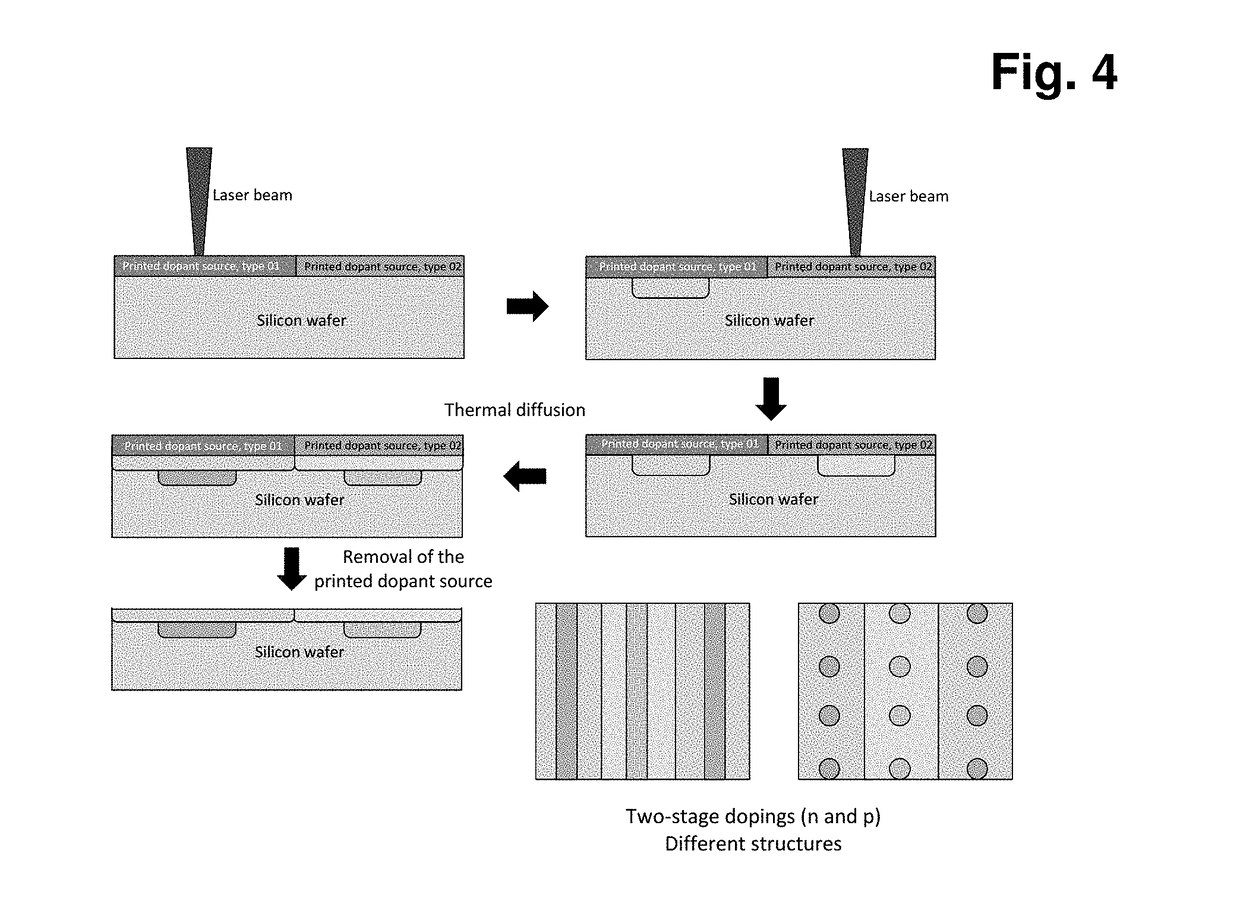

[0136]A textured 6″ CZ wafer with phosphorus base doping, having a resistivity of 2 ohm*cm, is printed with a boron doping paste, as described in the patent applications WO 2012 / 119686 A1 and WO 2014 / 101989 A1, using a steel screen (mounting angle)22.5° having a wire diameter 25 μm and an emulsion thickness of 10 μm using a doctor-blade speed of 110 mm / s, a doctor-blade pressure of 1 bar and a printing screen separation of 1 mm, where, depending on the other printing parameters, a layer thickness between 100 nm and 400 nm becomes established after complete drying at 600° C. After printing, the printed-on paste is dried for three minutes at 300° C. on a conventional laboratory hotplate. The wafer is then treated in predefined fields with the aid of an Nd:YAG nanosecond laser having a wavelength of 532 nm and using various laser fluences acting on the dried-on dopant source. The dopings of the various fields on the wafer are subsequently determined with the aid of four-point measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com