Cyclic process using alkaline solutions created from electrolytically decarboxylated water as an atmosphereic co2 collector followed by repeated electrochemical recovery of co2 with simultaneous production of dihydrogen for liquid hydrocarbon synthesis

a technology of electrolysis decarboxylation and alkaline solutions, which is applied in the direction of electrolysis components, products, separation processes, etc., can solve the problems of high energy consumption of alkaline solutions, deformation of alkaline solutions, and deformation of mea,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

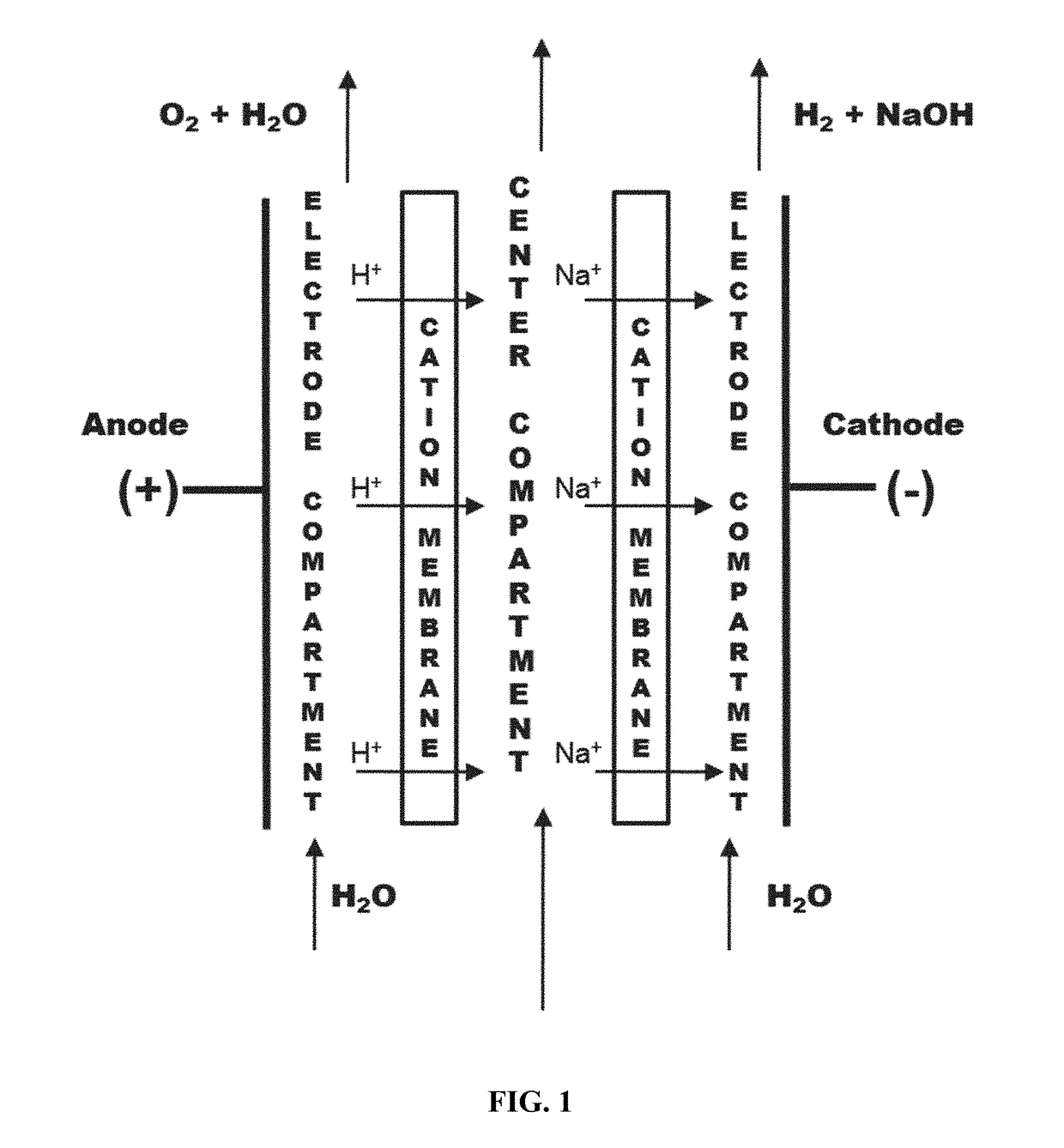

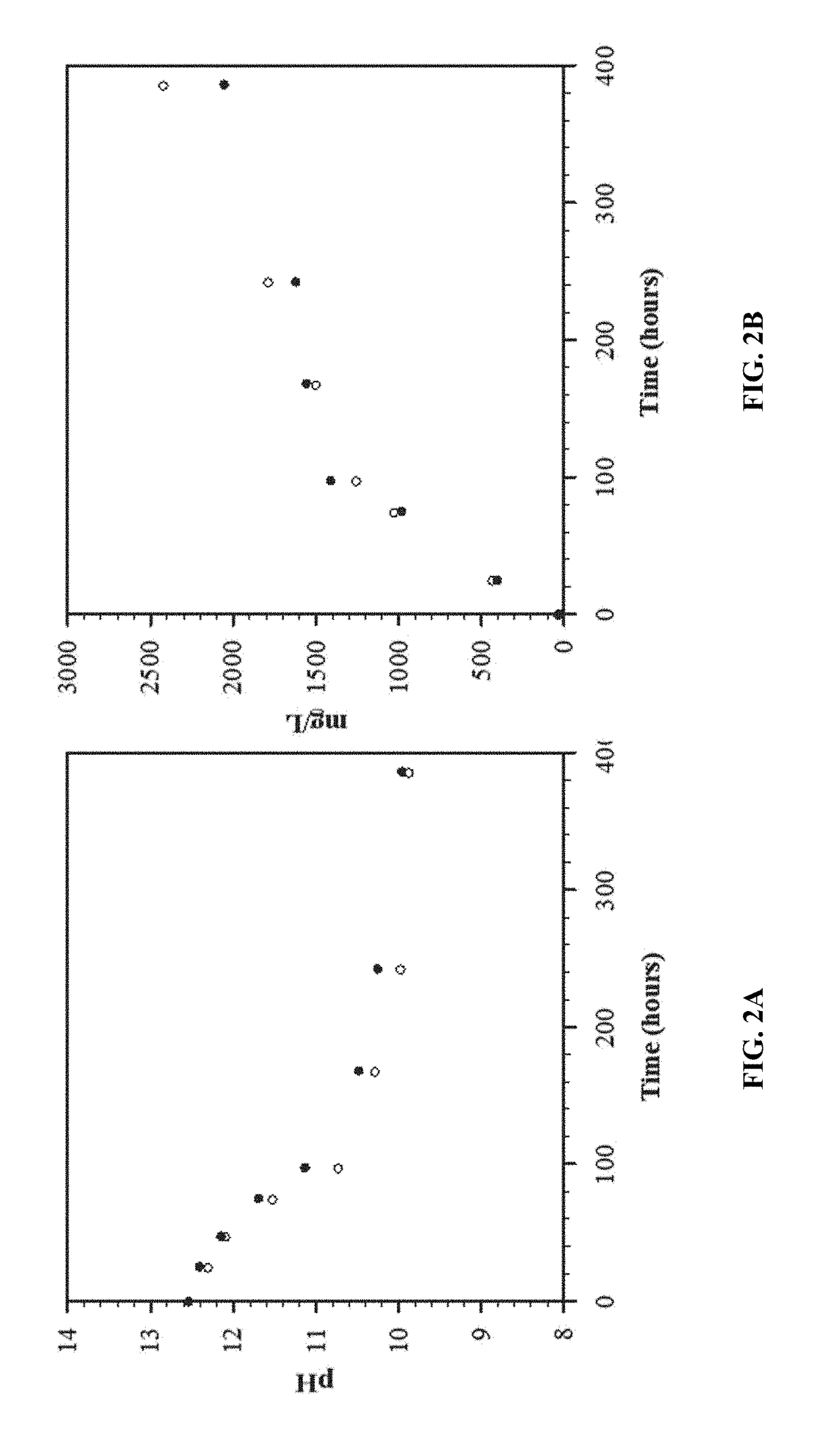

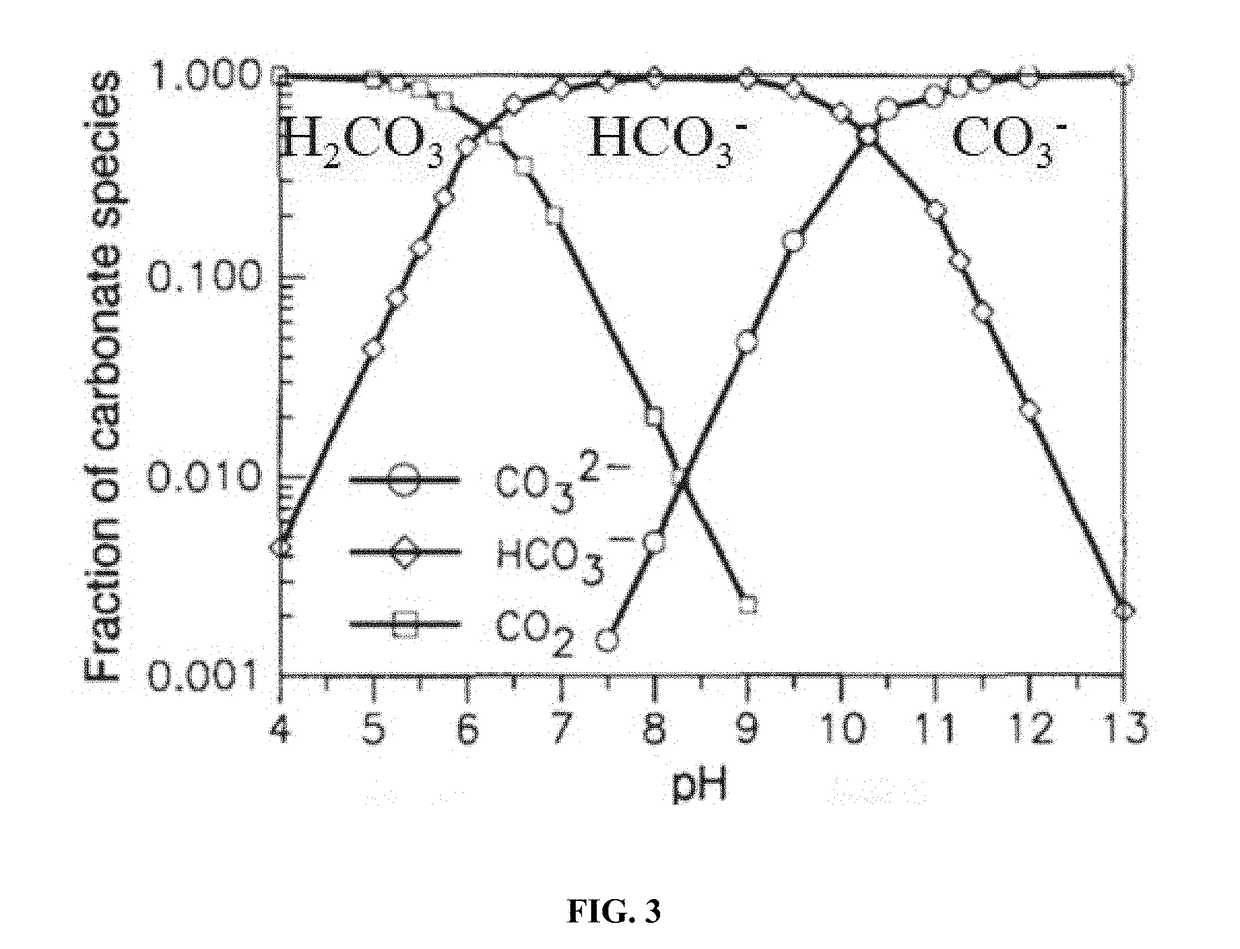

[0021]The present invention provides a cyclic process using alkaline solutions created from electrolytically decarboxylated water as an atmospheric CO2 collector followed by repeated electrochemical recovery of CO2 with simultaneous production of dihydrogen for liquid hydrocarbon synthesis as stored energy. After the inorganic carbon ([CO2]T) from alkaline water sources is removed, a much stronger alkaline solution is formed that is capable of re-equilibrating with CO2 from the atmosphere by chemical absorption so that the alkaline water can be reprocessed electrochemically. This cyclical direct CO2 capture and recovery from air and simultaneous production of dihydrogen is the central feature of this invention.

[0022]Seawater (pH 7.4 to 8.4) or any alkaline solution is processed for repeated recovery of CO2 to be used as feedstock to synthesize fuel. The inorganic CO2 (in the form of bicarbonate and carbonate) removed from the alkaline solutions is a weak base and its replacement by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com