Flex-Fuel Hydrogen Reformer for IC Engines and Gas Turbines

a hydrogen reformer and ic engine technology, applied in chemical/physical/physical-chemical processes, chemical apparatus and processes, chemical/physical/physical-chemical processes, etc., can solve the problems of permanent damage to the engine, inability to avoid coke formation in the reaction zone, and the pre-engine hydrogen reformer has not been successfully developed as commercial products, so as to improve the durability and the operating life of the catalyst, and the effect of high heat capacity of co2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0090]A larger laboratory reactor system which had more I / O modules than the one shown in FIG. 10 was used to study the catalytic autothermal reforming of bio-ethanol for hydrogen production. Here, a Simatic S7-400 PLC, all interface modules and the step-7 communication software were purchased from Siemens, and were installed and assembled together with a laptop computer as the main control computer.

[0091]A custom master control program stored in the main laptop computer was written in visual Basic to run the whole reactor system automatically. To operate the laboratory reactor system, the operator pushed the start-up button, turned on the external power supply relays and initiated the control program to start the test. According to the procedures written in the master control program, the PC would download the pre-defined set points simultaneously to the mass flow meters, metering pumps and furnaces. It would then turn on the solenoid valves according the pre-determined sequence to...

example 2

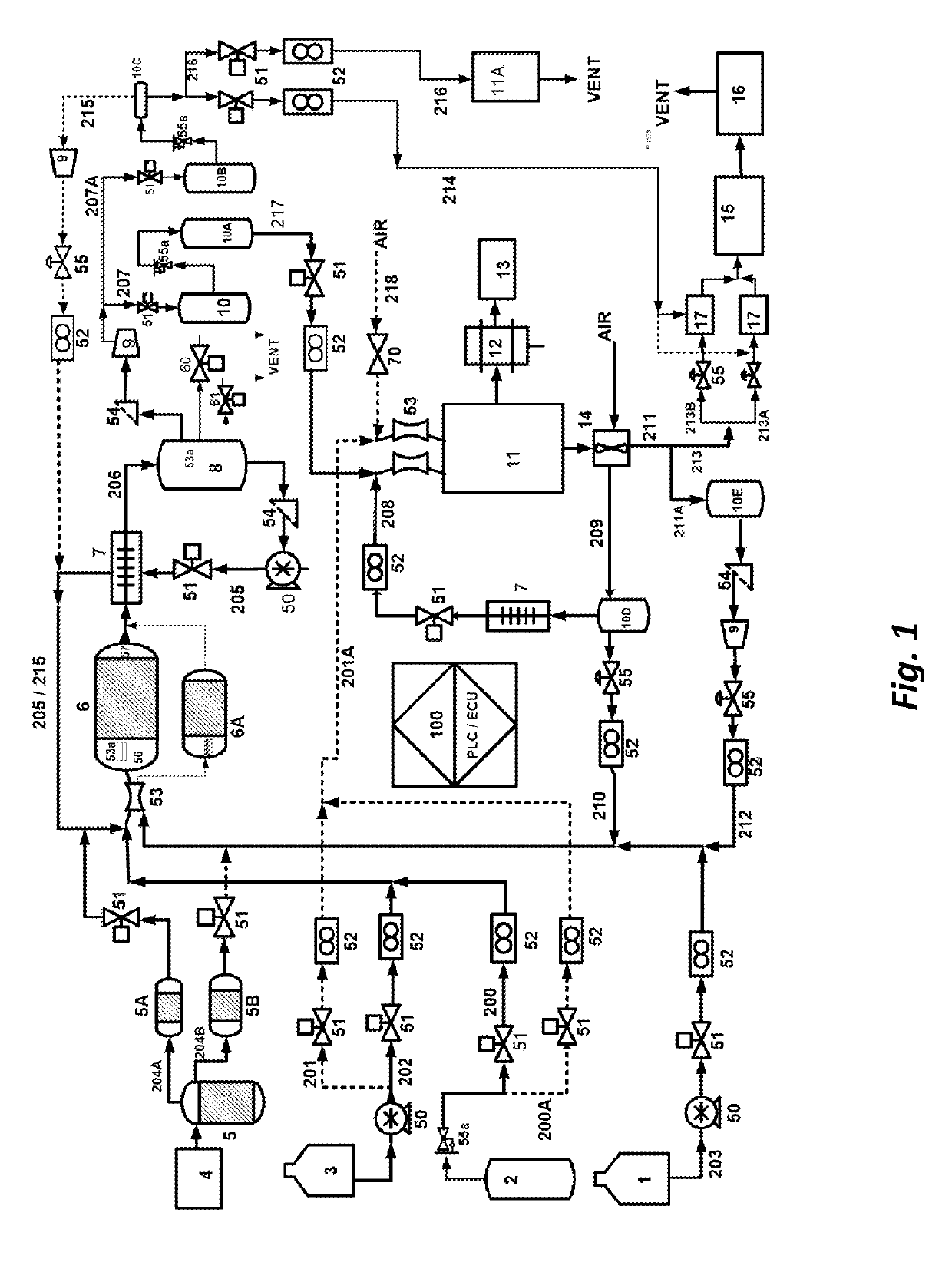

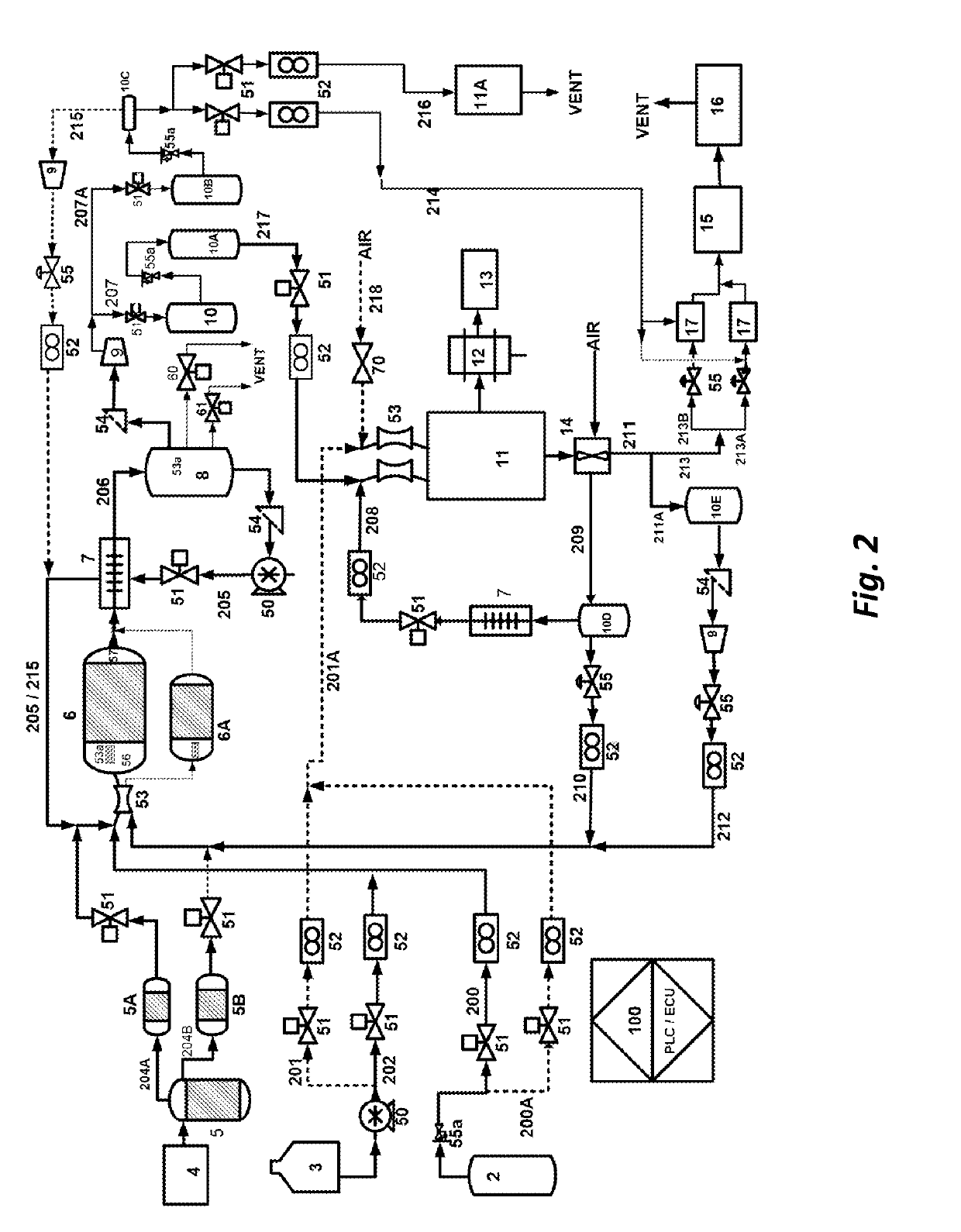

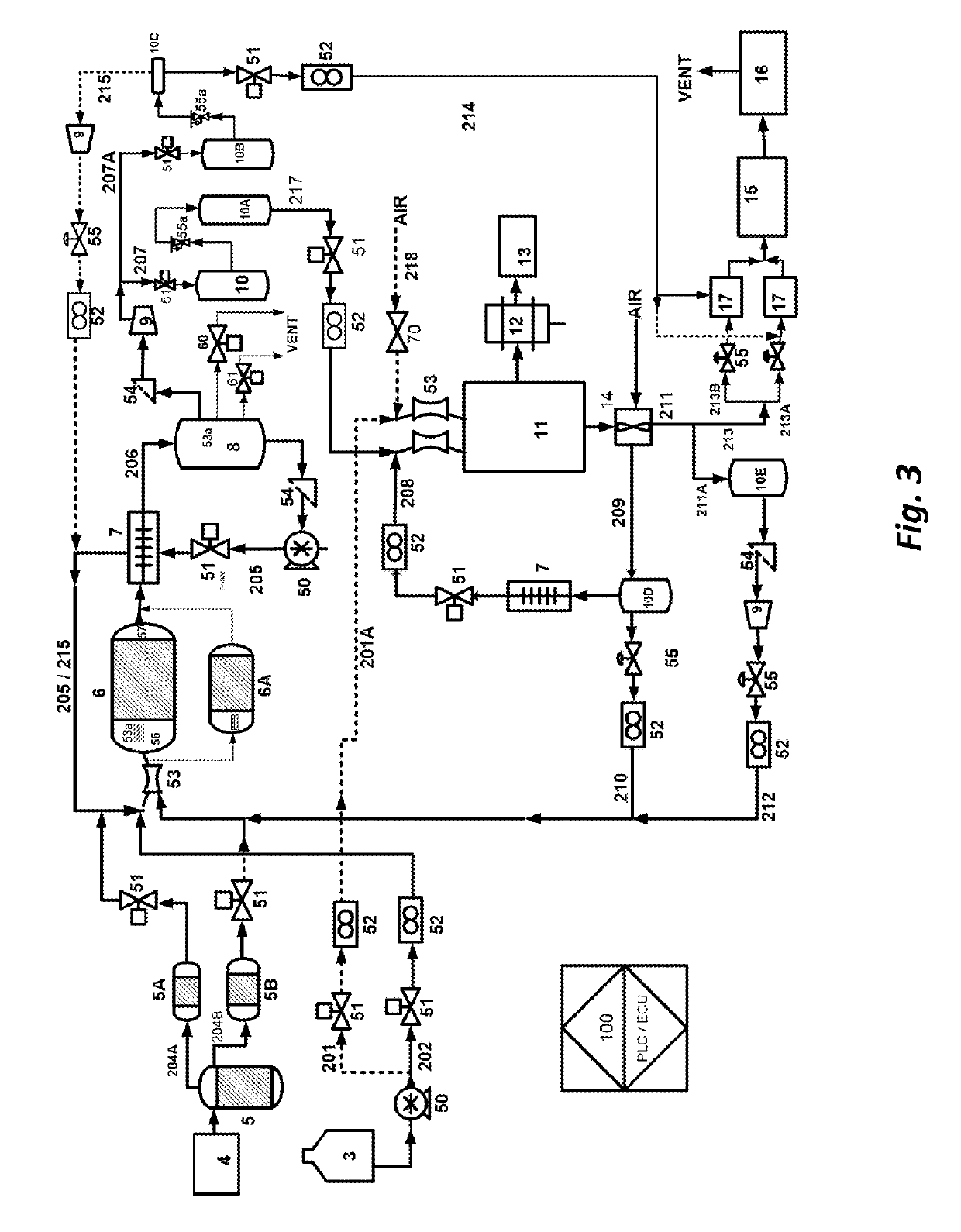

[0093]As shown in FIG. 10, a DL-260 CPU PLC with digital input, digital output, analog input, analog output, ethernet communication module and thermocouple interface modules were purchased from www.Automation Direct.com; In this simple and cheaper control system, the valves #51 are connected to the digital output module; The mass flow meters (Tylan mass flow meters from www.ebay.com) and one water metering pump (model QV-#RHOCKC from Fluid Metering Inc.) are connected to the analog output and also to the analog input modules, and several type K thermocouples are connected to the thermocouple module.

[0094]A small Acer ASPIRE ONE laptop computer running Window XP is used as a master computer. A master control software which is written in visual Basic is used to download flow controllers' set points, to open / close valves, to monitor / control reactor temperatures, to monitor / record the status of each device, to carry out the experimental sequences and the method of operating this Flex-Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com