A co to co2 combustion promoter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

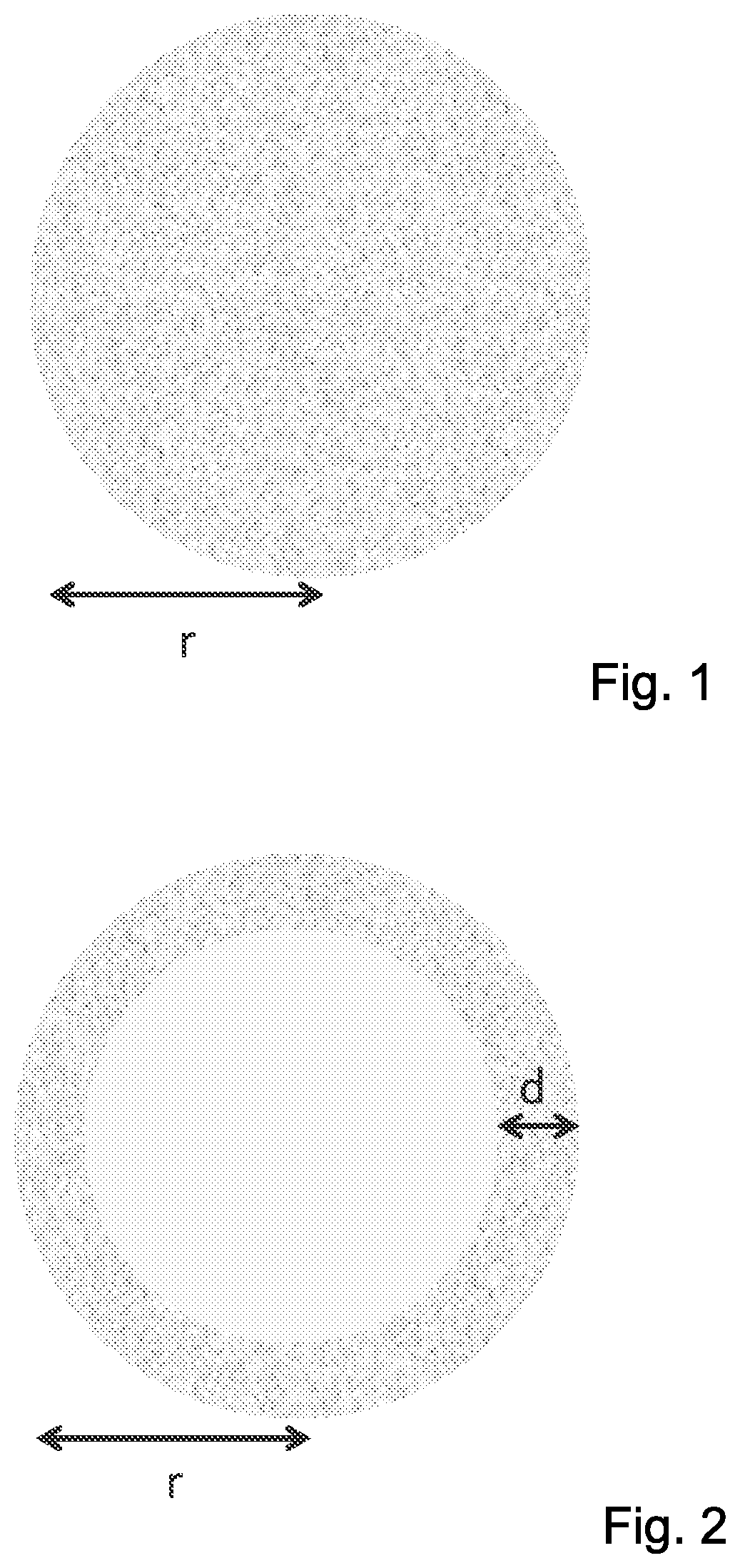

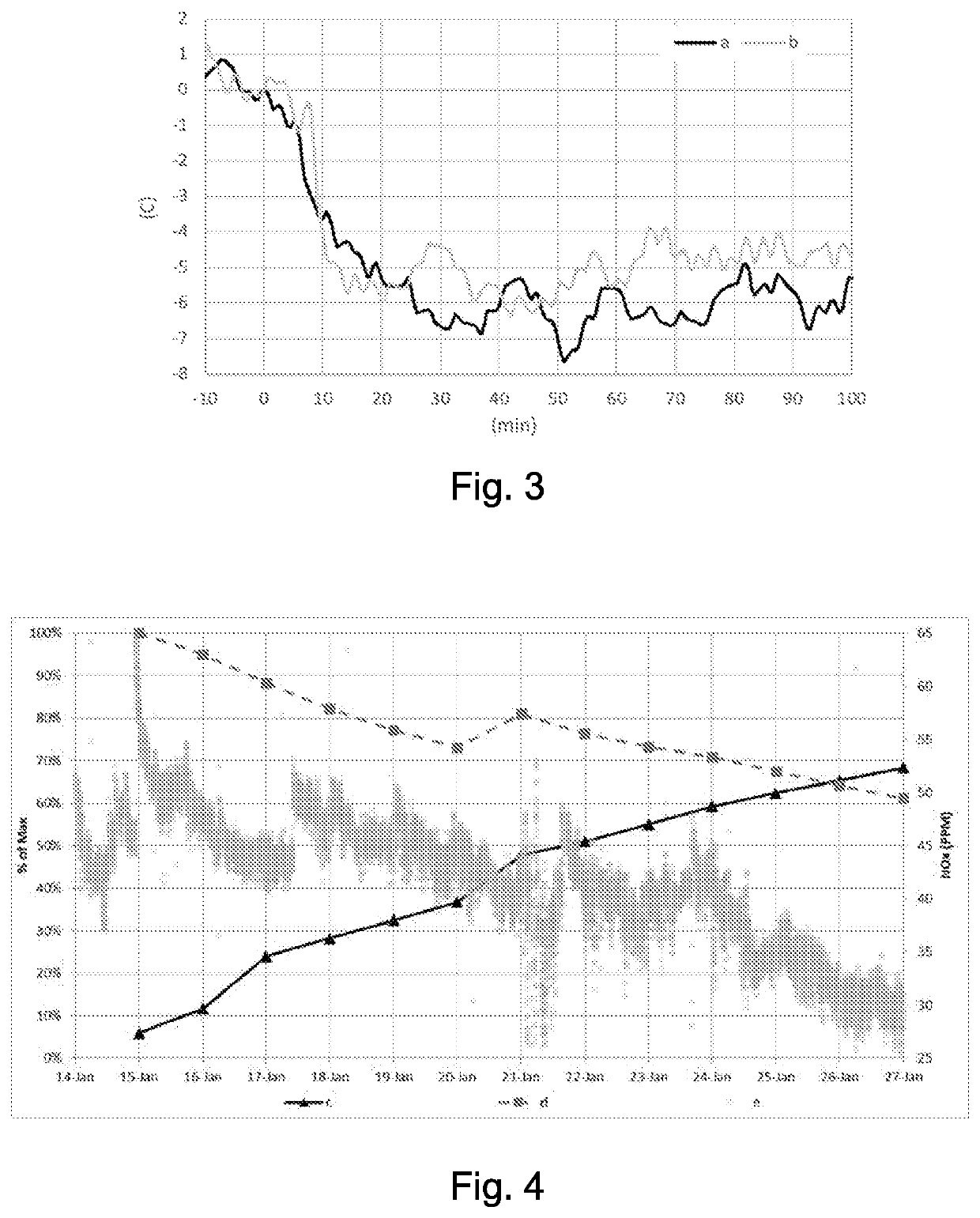

[0061]A two-step impregnation was carried out using a high purity gamma alumina support as purchased from Sasol. In the first step, 10 g of alumina powder was impregnated with water to fill 90% of the pore volume. At a pore volume of 0.5 mL / g, 4.5 mL of water was required for 10 g of alumina powder. For the second step, the wet alumina particles from step 1 with 90% of the pore volume filled with water were impregnated with a solution of palladium nitrate and dried to achieve an eggshell of palladium on the particle surface. The second impregnation step was completed before the pre-filled alumina particles were dried. After completing both impregnation steps, the impregnated particles were calcined at 600° C. for 1 hour to form a particle with the composition in accordance with this invention.

example 2

[0062]0.1 g of the composition of Example 1 was mixed with 10 g of a commercial FCC catalyst. The mixture was then used to measure the oxidation of CO in a fluid bed reactor fitted with a thermocouple. The catalyst bed was heated to 600° C. prior to the start of CO / O2 flow. Oxidation response was measured using a mixture of 1.8 v / v % CO and 0.9 v / v % O2, balanced with He, under a gas flow rate of 1000 cc / min. The oxidation response is a measure of the amount of CO which is combusted (oxidized) to CO2.

example 3

[0065]A two-step impregnation was carried out using a high purity gamma alumina support as purchased from Sasol. In the first step, 10 g of alumina powder was impregnated with water to fill 90% of the pore volume. At a pore volume of 0.5 mL / g, 4.5 mL of water was required for 10 g of alumina powder. For the second step, the wet alumina particles from step 1 with 90% of the pore volume filled with water were impregnated with a solution of platinum nitrate and dried to achieve an eggshell of platinum on the particle surface. The second impregnation step was completed before the pre-filled alumina particles were dried. After completing both impregnation steps, the impregnated particles were calcined at 600° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com