Extrusion

a technology of nutritional composition and expansion, applied in the field of expansion, can solve the problems of limited adaptation of hardware configuration and machinery used in conventional processes, and achieve the effects of convenient retrofitting into existing processing plants, high flexibility, and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

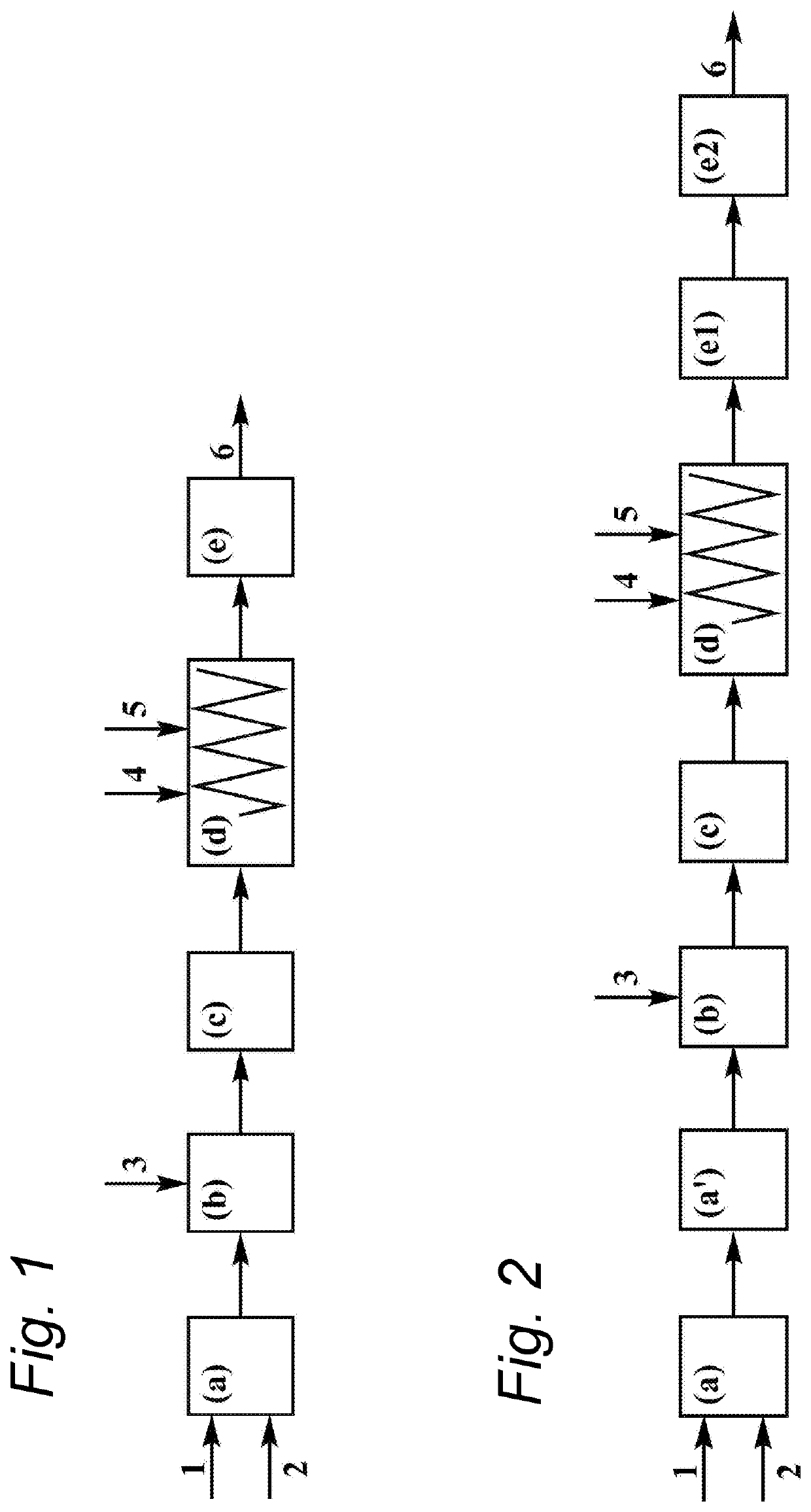

Method used

Image

Examples

example 1

[0116]A process flow was generated for production of an infant formula intended for infants with an age of between 0 and 6 months. In a first step, demineralized whey (Demin Whey, flowrate 3166 kg / h), liquid whey protein concentrate 80 (WPC80, flowrate 430 kg / h), water (flowrate 677.2 kg / h) and the required amounts of micronutrients (i.e. vitamins and minerals) were compounded into an aqueous liquid with a total solids content (% TS) of 25 at a temperature of 35° C., and processed at a flowrate of 4419 kg / h.

[0117]The aqueous liquid was subsequently heat treated at 121.0° C. with a residence time of 2.89 seconds to achieve an F0 of 2.4. After cooling, the heated solution is subsequently fed into an evaporator for concentration purposes during which water was removed at a flowrate of 1943.5 kg / h. After evaporation, the aqueous solution has a % TS of 44.6 and is conveyed with a flowrate of 2475.5 at a temperature of 60° C. to the oil injector. Oils necessary to produce the infant formu...

example 2

[0119]A process flow was generated for production of an infant formula intended for infants with an age of between 6 and 12 months. In a first step, liquid whey protein concentrate 35 (WPC35, flowrate 1019.4 kg / h), water flowrate 3140.7 kg / h) and the required amounts of micronutrients (i.e.

[0120]vitamins and minerals) were compounded into an aqueous liquid with a total solids content (% TS) of 25 at a temperature of 35° C., and processed at a flowrate of 4236.5 kg / h. Protein content of the aqueous liquid was 8.44 wt %.

[0121]The aqueous liquid was subsequently heat treated at 121.0° C. with a residence time of 2.89 seconds to achieve an F0 of 2.4. After cooling, the heated solution is subsequently fed into an evaporator for concentration purposes. After evaporation, during which water was removed with a flowrate of 1703.1 kg / h, the aqueous solution has a % TS of 41.8 and is conveyed with a flowrate of 2533.4 at a temperature of 60° C. to the oil injector. Oils necessary to produce th...

example 3

[0123]Data mentioned in example 1 and 2 were generated using the gPROMS gFormulatedProducts 1.2.2 simulation model from Process Systems Enterprise (PSE). Mass balance models used were steady state, meaning no accumulation in time is applied. Models were applied on a macro level without applying any discretization method.

[0124]For evaporation / concentration the mass balance of equation (1) was applied.

0=φmin−φmout−φmexap (1)

It states that the amount of evaporated water or water otherwise removed

(kgs)

from a stream, plus the outlet from a stream should be equal to an inlet stream. From this perspective the outlet total solids

(kgkg)

were calculated via equation (2):

xsolidsout=xsolidsinφminφmout(2)

This was applied under the assumption that extracted water, extracted via evaporation or any other technology, is pure water.

[0125]The same approach was used for mixing of different streams either within compounding (i.e. preparation of an aqueous mixture prior to heat treatment step a)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com