Rare earth aluminates and gallates supported rhodium catalysts for catalytic partial oxidation of hydrocarbons

a technology of rhodium catalyst and rare earth aluminates, which is applied in the direction of metal/metal-oxide/metal-hydroxide catalyst, combustible gas purification/modification, chemical production, etc., can solve the problems of catalyst deactivation, reaction that is simply too slow and/or efficient to be economical, and uneconomical at best and ineffective at worst, so as to improve the composition of the catalys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

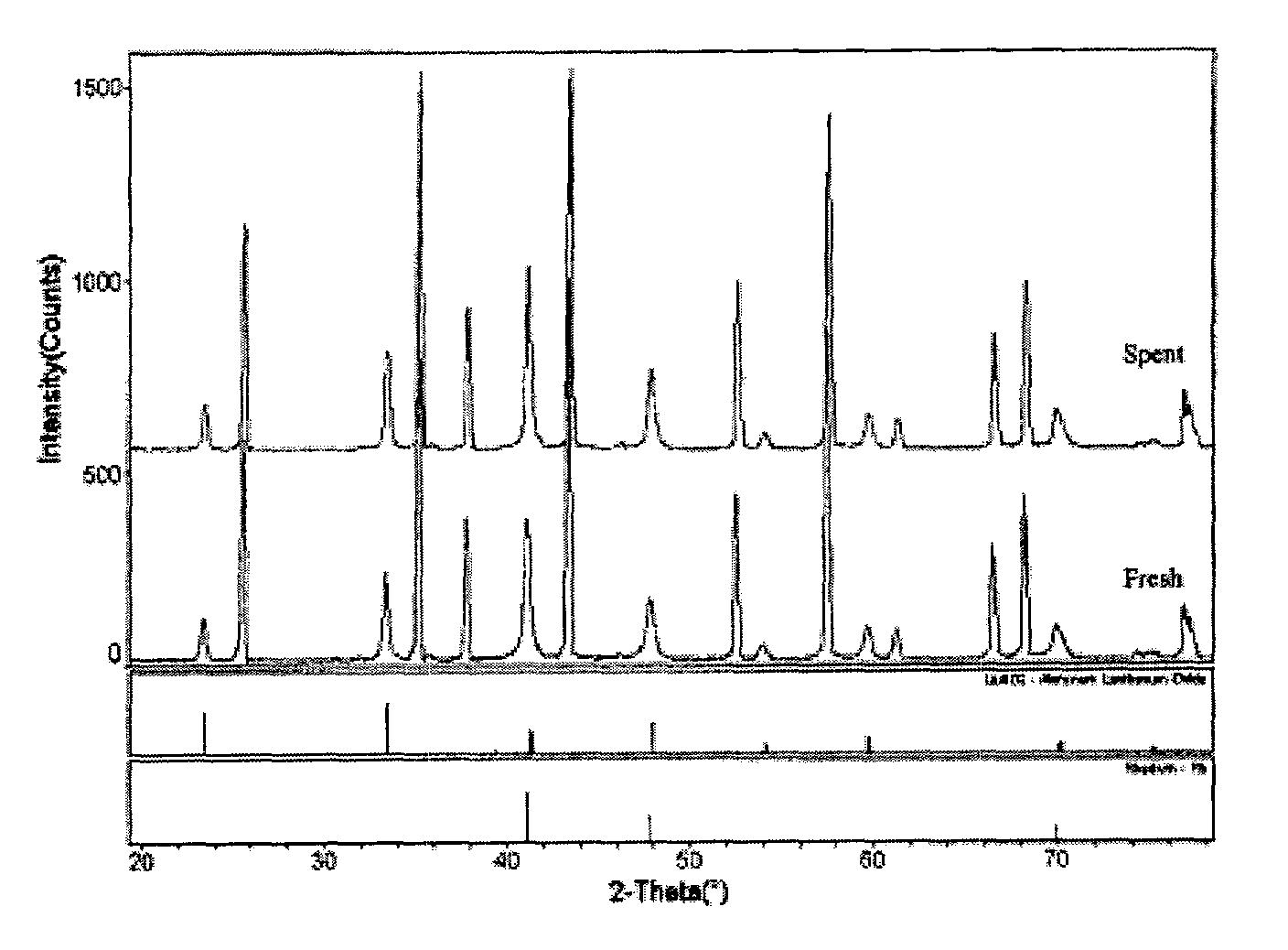

[0034]A rare earth (La) modified support material was prepared using a standard incipient wetness technique. 20 g of alpha alumina (30–50 mesh) was impregnated with an aqueous solution of La(NO3)3. The impregnated material was then dried in an oven at 100° C. overnight. The support material was further calcined at 1050° C. in air for 2 hours to allow the solid-state reaction between the alumina and lanthanum nitrate to take place. After calcination, the composition was found to be 6.40 wt % LaAlO3 on Al2O3.

example 2

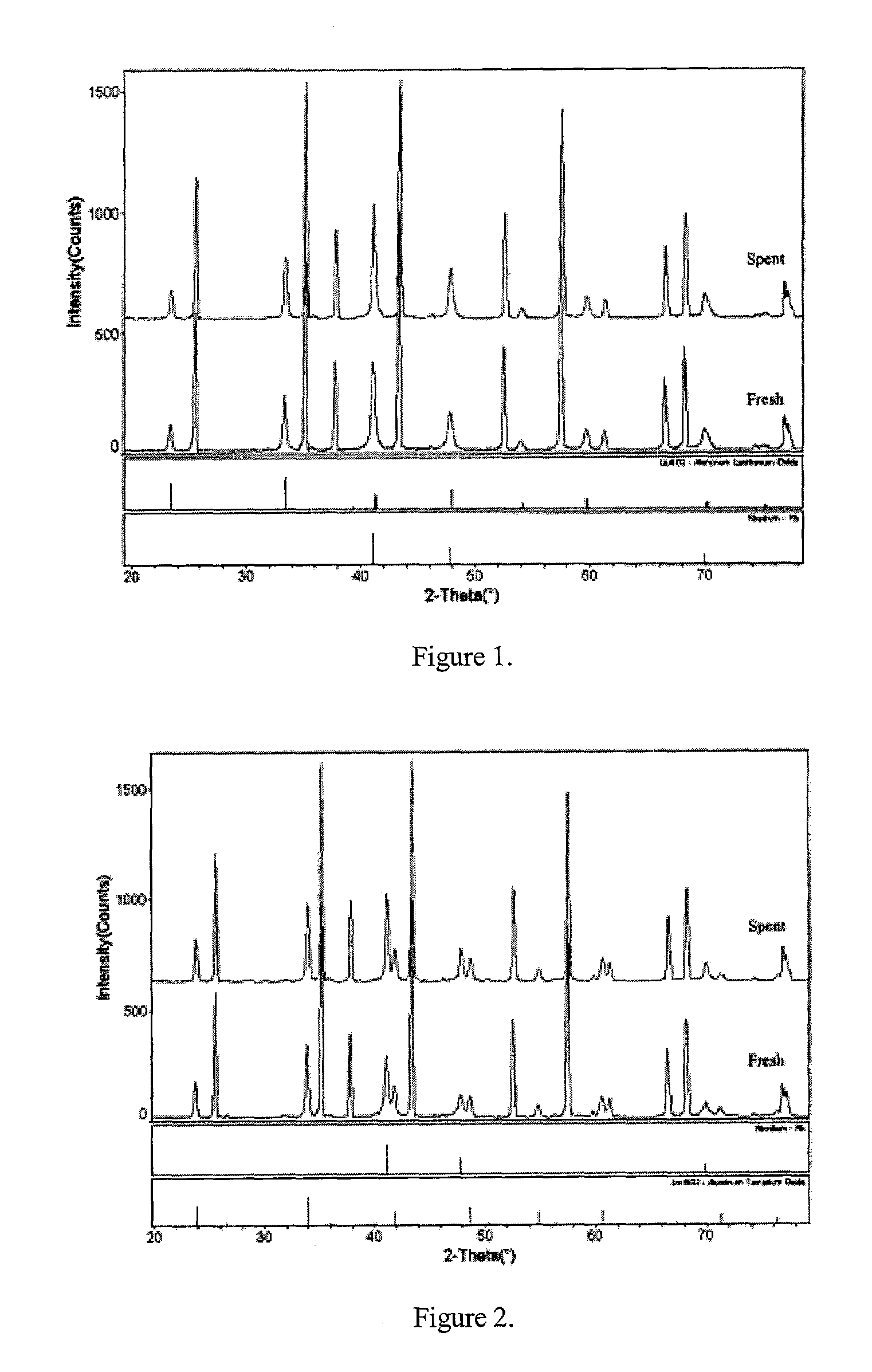

[0035]A rare earth (Sm) modified support material was prepared using a standard incipient wetness technique. 20 g of alpha alumina (30–50 mesh) impregnated with an aqueous solution of Sm(NO3)3. The impregnated material was then dried in an oven at 100° C. overnight. The support material was further calcined at 1050° C. in air for 2 hours to allow the solid-state reaction between the alumina and samarium nitrate to take place. After calcination, the composition was found to be 6.79 wt % SmAlO3 on Al2O3.

example 3

[0036]Catalyst A was prepared from the rare earth modified support material in Example 1. The catalyst was prepared by incipient wetness impregnation of the LaAlO3 / Al2O3 particulate support material with a aqueous solution of rhodium chloride hydrate (RhCl3.xH2O. The nominal loading for Rh was 4% by weight. The rhodium impregnated modified support was dried at 100° C. overnight and then calcined at 600° C. in air for 3 hours. The calcined catalyst precursor was then reduced in a tube furnace under a flow of 300 ml / 300 ml H2 / N2 at 500° C. for 3 hours prior to catalytic testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com