Method and apparatus for producing synergistic biocide

a biocide and synergistic technology, applied in biocide, water/sewage treatment by oxidation, sustainable biological treatment, etc., can solve the problems of uncontrollable growth of microorganisms in industrial production systems, interference with a wide range of important industrial processes, and affecting the quality of products, so as to prevent the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

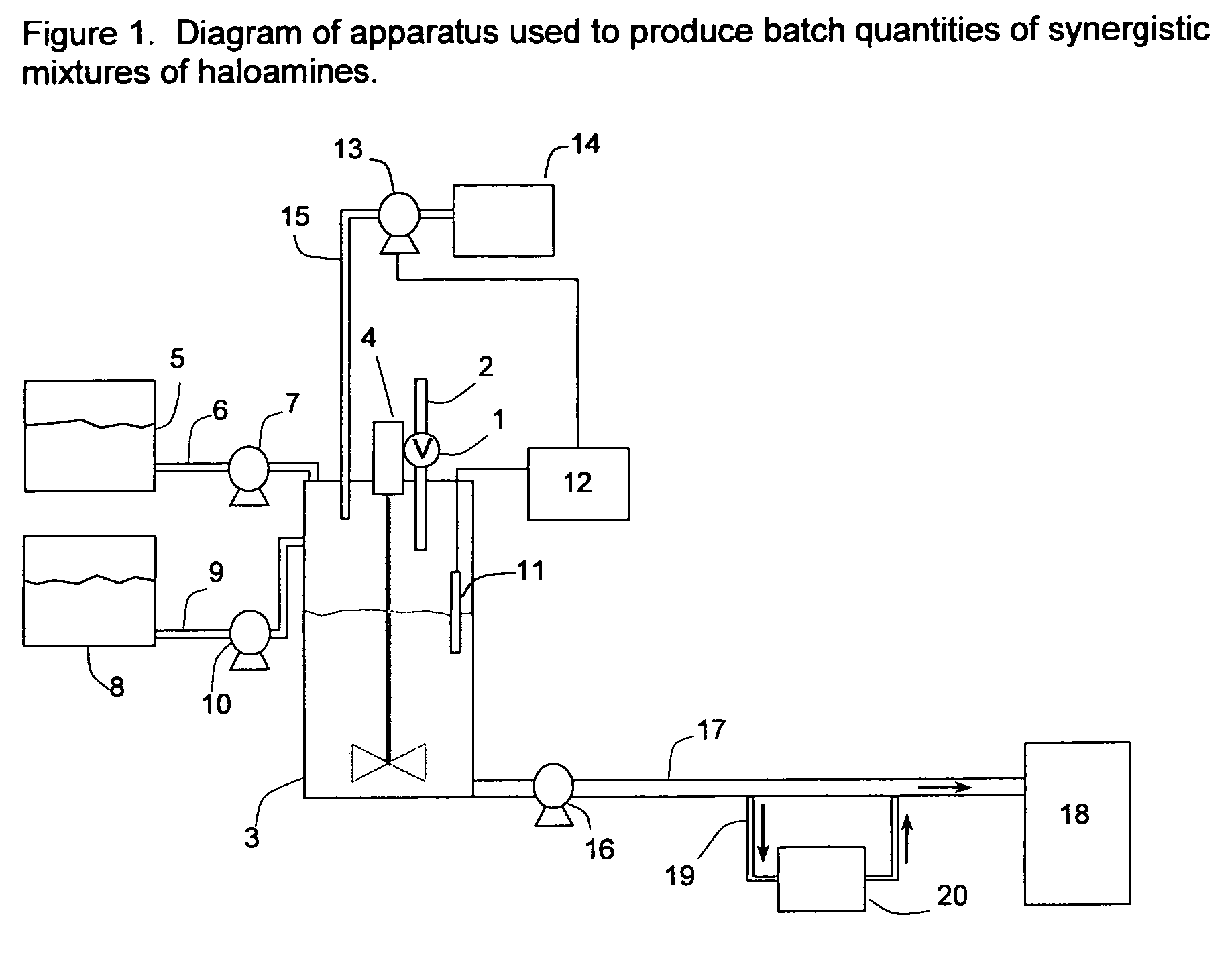

Method used

Image

Examples

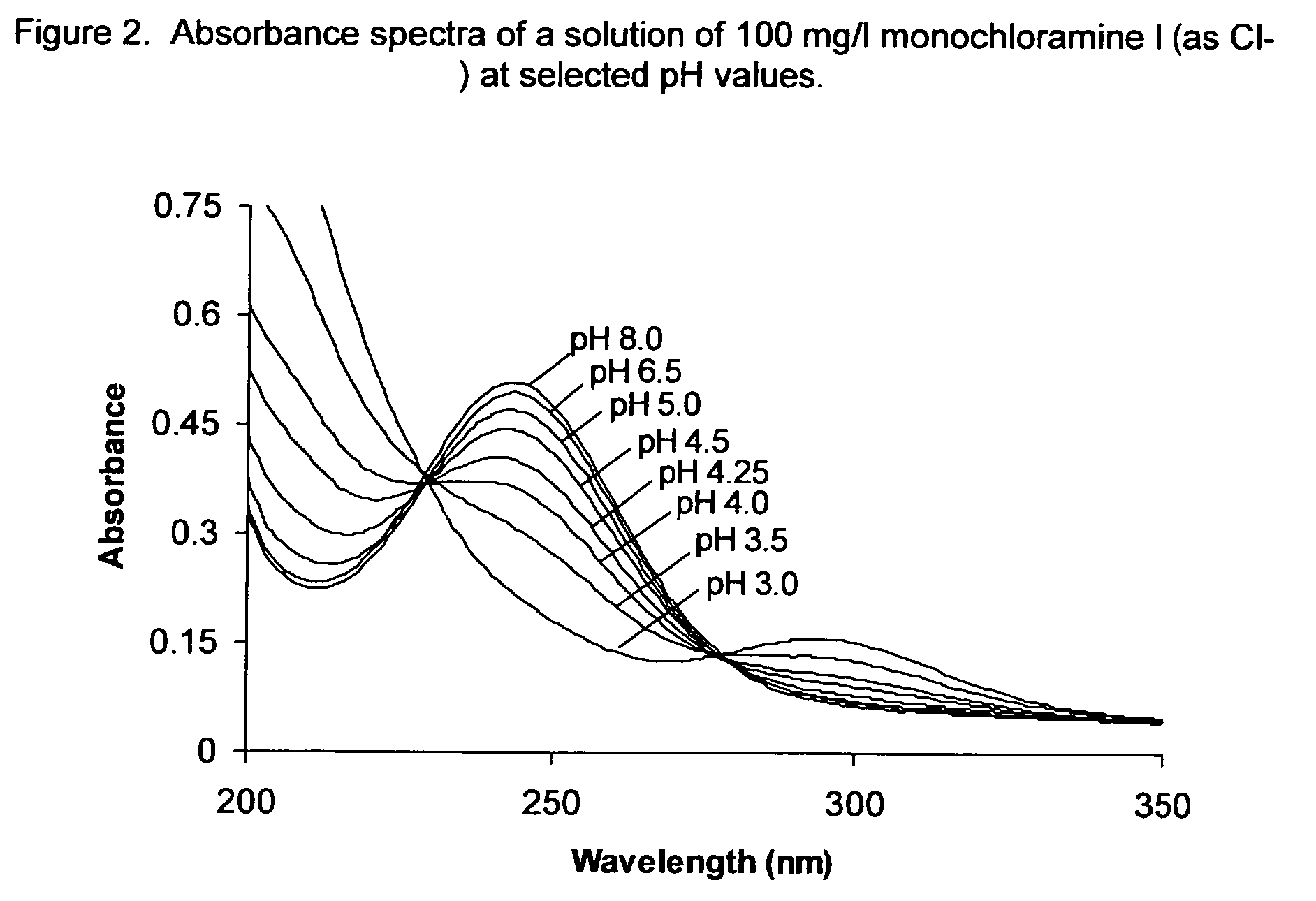

example 1

[0068]The efficacies of the individual haloamines and the synergistic combination produced with the apparatus described above were determined using a consortium of microorganisms and a dose-response protocol. Concentrations of monochloramine and dichloramine reported herein are in units of milligrams per liter as measured by Cl2 analysis; the Hach DPD chlorine test (Hach Company, Loveland, Colo.) was used to measure the total available chlorine concentrations and are expressed as milligrams per liter as Cl2. The DPD assay is based on the amount of chlorine in a sample that reacts with N,N-diethyl-p-phenylenediamine oxalate. To determine the amount of monochloramine or dichloramine in a sample, an aliquot of the sample was transferred to a clean container, diluted with deionized water, as appropriate, and assayed according to the Hach DPD chlorine test. The assay measures the total amount of chlorine that can react with the indicator reagent. The reaction is measured by determining t...

example 2

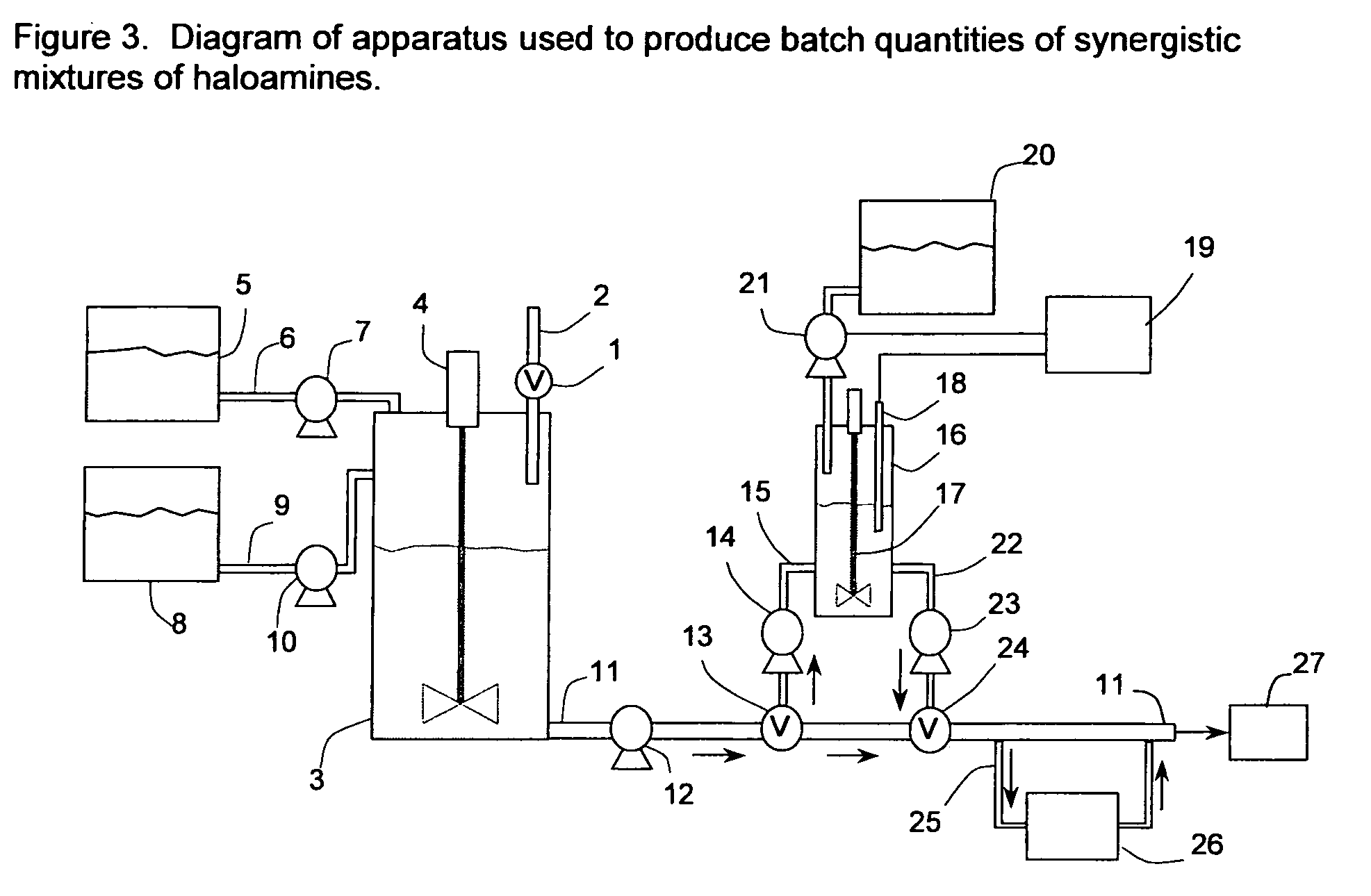

[0077]The apparatus was used to produce the synergistic biocide in which the ratio of monochloramine to dichloramine was changed by adjusting the flow rate of monochloramine through mixing chamber 16. In this example, the flow rate was incrementally adjusted in a manner to allow the ratio of monochloramine to dichloramine to be 9 parts monochloramine to 1 part dichloramine. Each incremental change was carried out in a manner to allow for the absorbance spectrum (FIG. 5) to become stable at which time samples of the 9 to 1 (monochloramine to dichloramine) biocide mixture as well as the monochloramine solution in reservoir 3 and the dichloramine solution in mixing chamber 16 were collected. The total chlorine concentration of each sample was determined to confirm the ratio was correct. Samples of the monochloramine and dichloramine solutions were mixed in appropriate volumes to obtain the 1:1 and 4:1 ratios.

[0078]The dose-challenge studies were carried out as previously described usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pH | aaaaa | aaaaa |

| concentrations | aaaaa | aaaaa |

| pH | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com