Internal combustion engine and a method for such an engine

a technology of internal combustion engine and combustion chamber, which is applied in the direction of machines/engines, electric control, speed sensing governors, etc., can solve the problems of increased material failure in the exhaust manifold, increased so as to reduce the thermal stress of the exhaust manifold. , the effect of effective reduction of the flow of cold air to the exhaust man

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

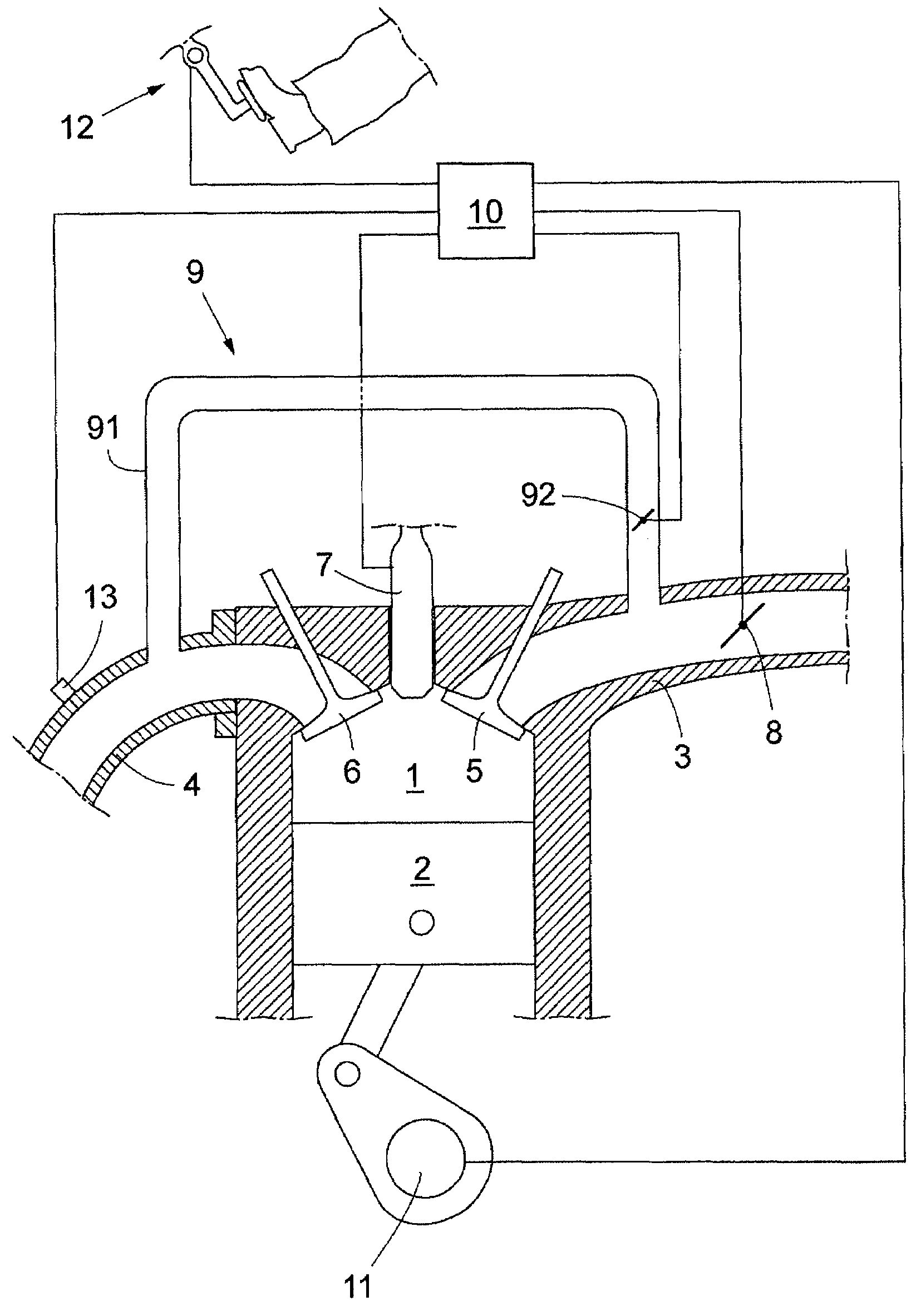

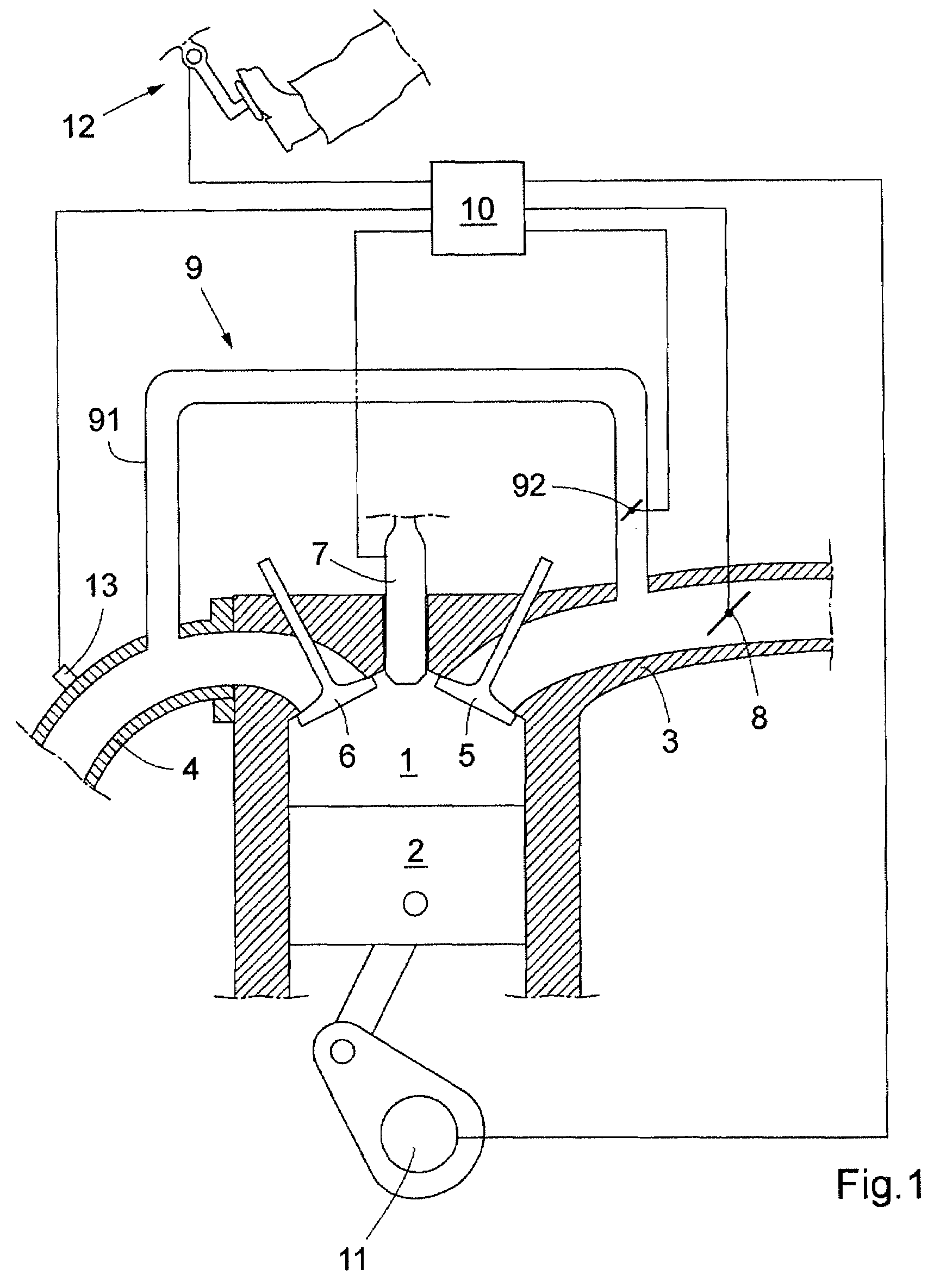

[0019]FIG. 1 shows schematically parts of an internal combustion engine, with compression ignition, for a vehicle. The engine comprises a cylinder 1 with a piston 2. The invention is suitable for engines with any number of cylinders. The engine further comprises an inlet and an exhaust manifold 3, 4, and an inlet and an exhaust valve 5, 6. A fuel injector 7 is arranged to inject fuel into the cylinder 2. More specifically, the fuel injector 7 is adapted to inject fuel periodically, at least once every work cycle of engine. A throttle valve 8 is provided in the inlet manifold 3 for controlling the air flow to the cylinders 2.

[0020]Further, in a manner known in the art, an exhaust gas recirculation (EGR) arrangement 9 is provided with a conduit 91 for guiding exhaust gas from the exhaust manifold 4 to the inlet manifold 3, and an exhaust gas recirculation (EGR) valve 92, for controlling the flow of re-circulated exhaust gas. The EGR arrangement 9, in particular the EGR valve 92, can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com