Volume Fresnel zone plates fabricated by laser direct writing

a laser direct writing and zone plate technology, applied in the field of volume fresnel zone plate fabricated by laser direct writing, can solve the problems of low diffraction efficiency of all previously studied zone plate, increased complication in fabrication, and difficulty in eliminating phase shift errors due to fabrication, etc., to achieve high diffraction efficiency and higher diffraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

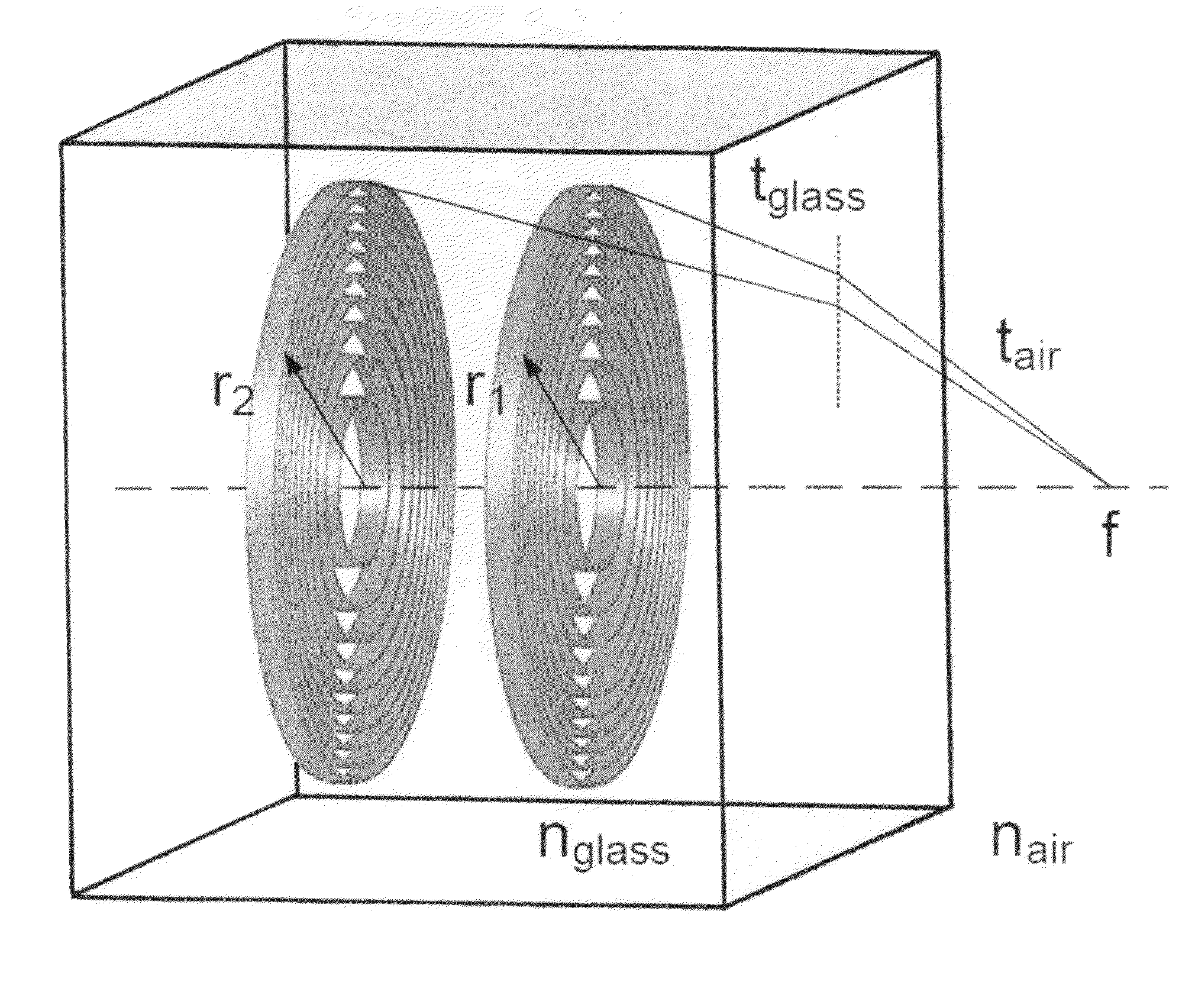

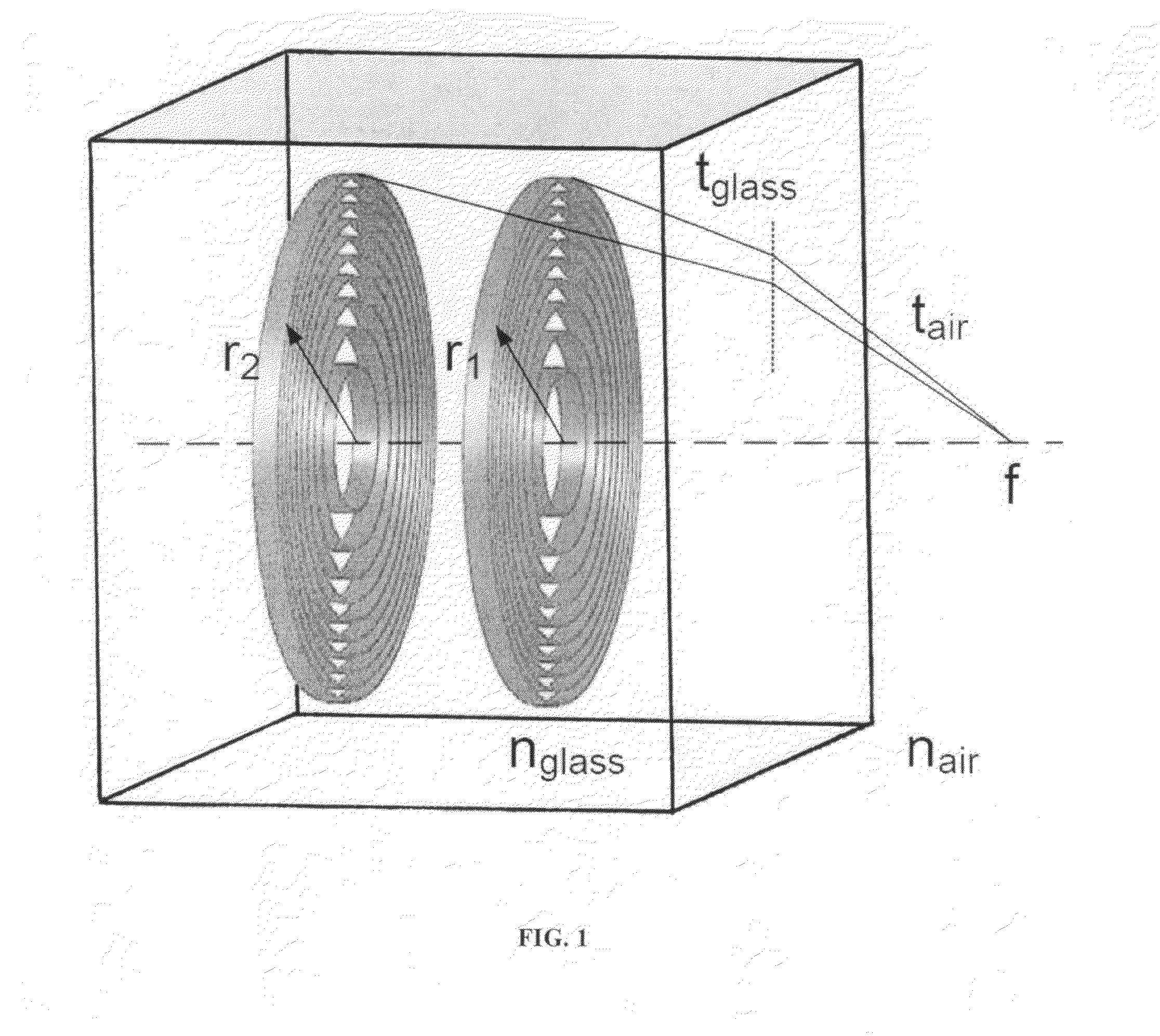

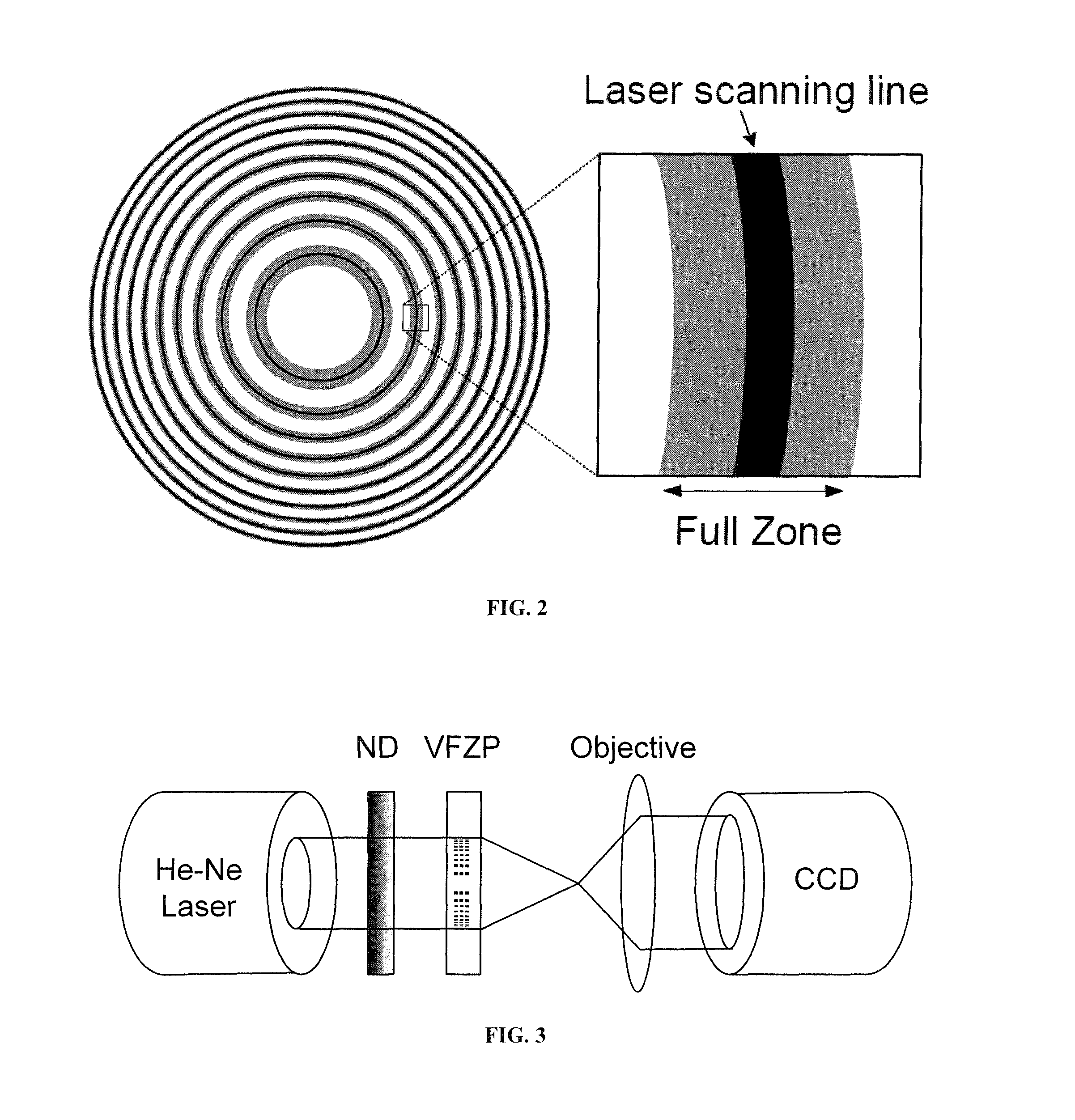

The present invention provides volume zone plates and related fabrication methods. The concept of a volume Fresnel zone plate is based on the realization that diffracted light from many Fresnel zone plates can be effectively coupled together to enhance the intensity at the focal spot. An incident plane wave is considered for the design. A volume Fresnel zone plate according to the present invention consists of a number of layers of modified zone plates centered on the same optical axis. A volume modified zone plate should satisfy two conditions: focal point matching and phase matching. First, each Fresnel zone plate inside a volume is designed specifically according to its relative location so that all the zone plates focus light exactly at the same focal point. In addition, the diffracted light from all the zone plates must be “in phase”, while the phase at the focal point can be chosen arbitrarily. In other words, the phase shifts produced by every zone plate are the same at the f...

embodiments

Second Set of Embodiments

For a second set of embodiments, as with others described above, a fused silica sample optically polished on all surfaces was fixed on a computer-controlled x-y-z air bearing stage which has a translational accuracy of 200 nm. The sample was irradiated by 90 fs pulses delivered by a Ti:sapphire amplified laser system at a central wavelength of 800 nm and 1 kHz repetition rate. The laser beam was attenuated before being focused inside the bulk of fused silica. An electronic shutter was connected to the computer controller, allowing the laser exposure and the stage movement to be synchronized. The fabrication process was monitored in real time via a CCD camera imaging on a TV screen.

In femtosecond laser direct writing, both the change in index of refraction and the shape of the filament where change of index of refraction occurs are sensitive to laser processing parameters such as laser frequency, pulse energy, scanning speed, focusing conditions and focusing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com