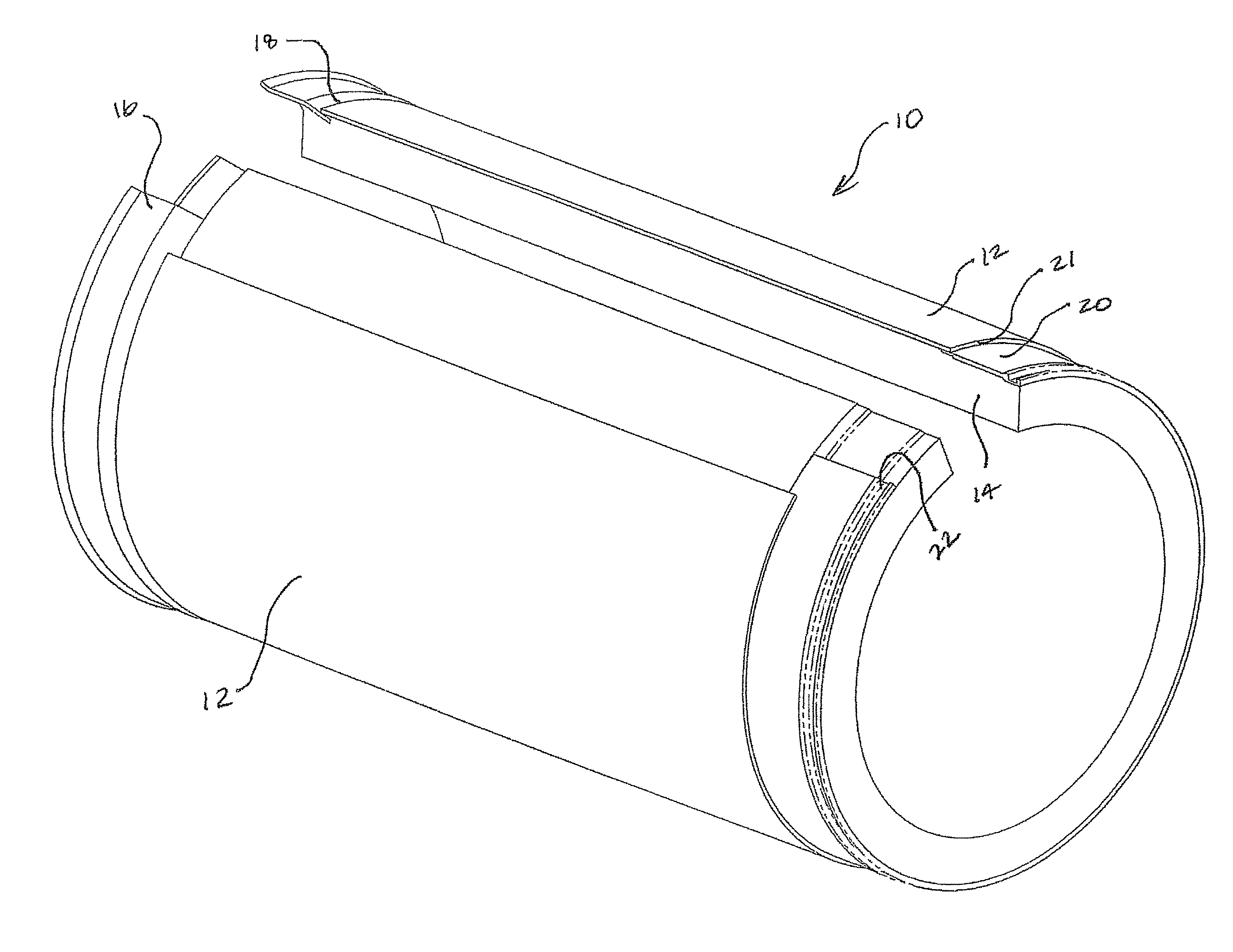

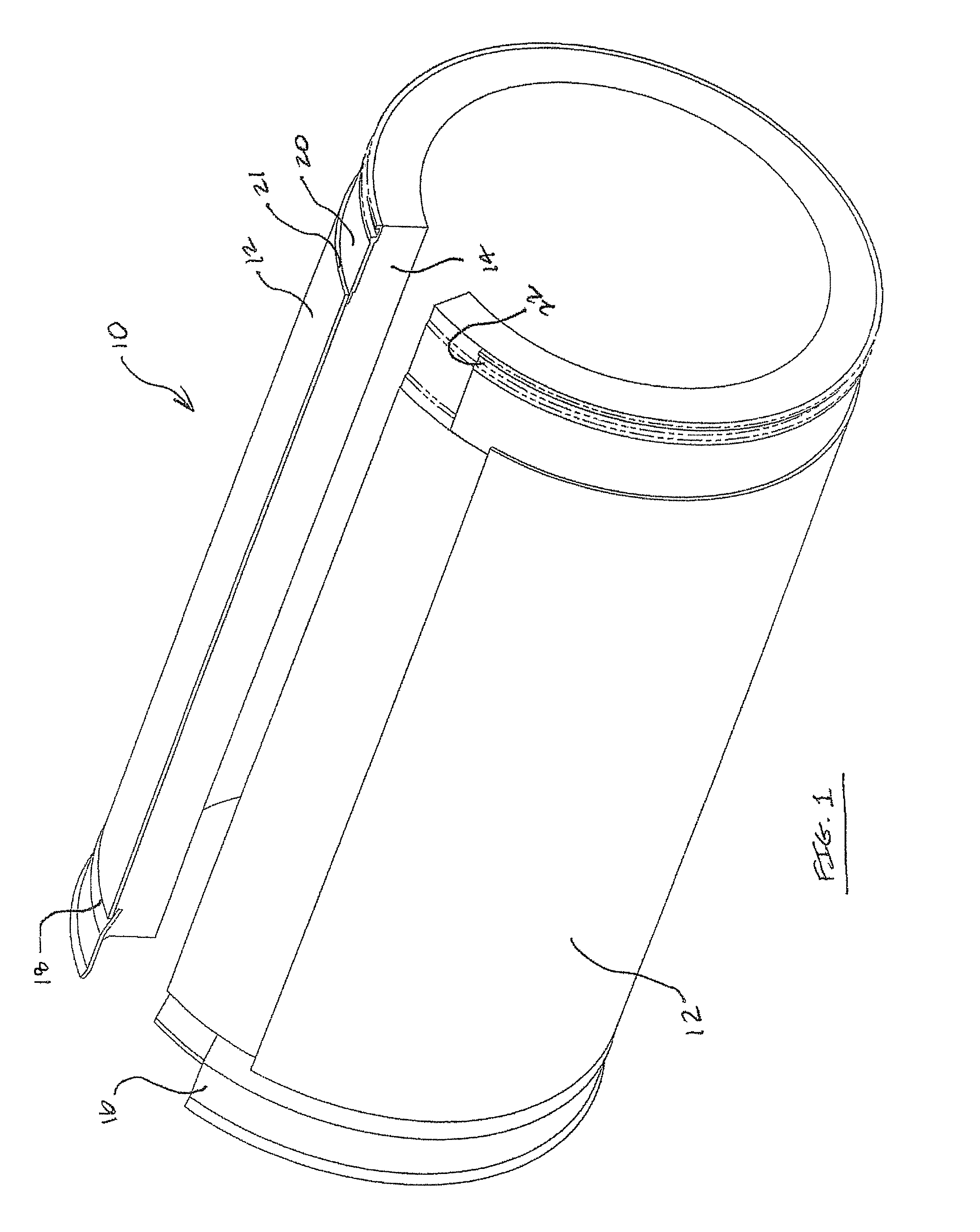

Pressure cast concrete or mortar lined steel pipes and methods of making the same

a technology of pressure cast concrete and steel pipes, which is applied in the field of pressure cast concrete or mortar lined steel pipes, can solve the problems of limiting the allowable design stress, cracks, and limited allowable strain in the concrete or mortar lining, and achieves the effect of saving raw material costs and reducing diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

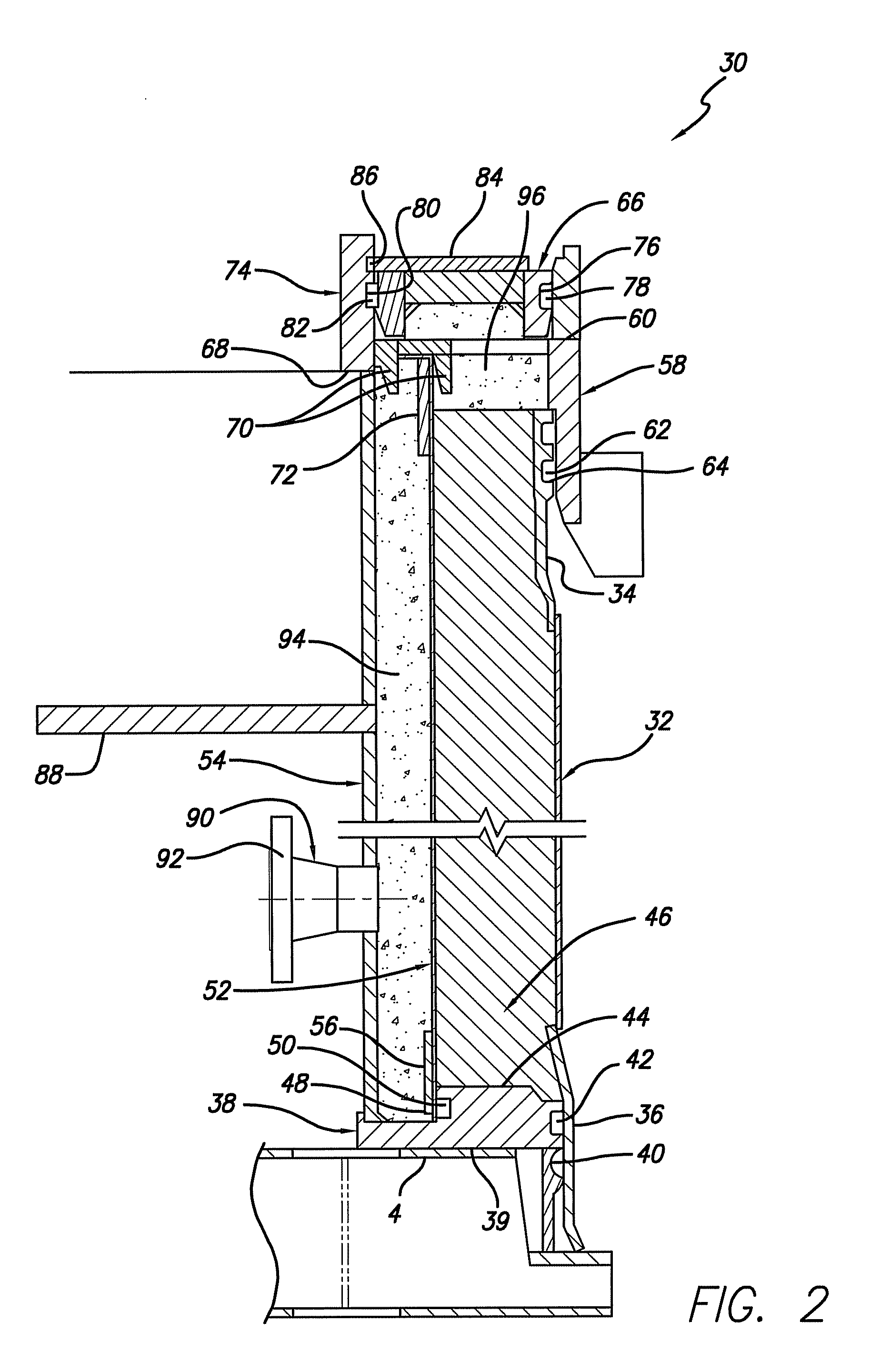

[0100]a PCSP was formed using the assembly illustrated in FIG. 2, having an metal shell inside diameter of approximately 92 inches, by delivering a concrete composition comprising approximately 750 lbs cement (Type I / II), 1490 lbs coarse aggregate, 1400 lbs sand, 319 lbs water, 60 fl oz high range water reducing admixture (Glenium 7700), 10 fl oz viscosity-modifying admixture (VMA 538), and comprising a small amount of air voids (2.5%), wherein the total weight of the composition was approximately 3959 lbs. If desired, a portion (15 to 20 percent by weight) of the cement component disclosed in the above composition can be replaced by an expansive agent, such as Komponent from CTS Cement Manufacturing Corp, to compensate for the shrinkage due to drying and creep. This composition was delivered into the concrete or mortar mold chamber. The collapsible inner mold member is positioned so that the inside diameter of the resulting cured concrete liner is approximately 84 inches. The metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com