Multibit single cell memory element having tapered contact

a memory element and multi-cell technology, applied in the field of memory element having a tapered contact layer, can solve the problems of increased reduced performance, and increased cost, and achieve the effect of reducing the complexity of the computer's architectur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

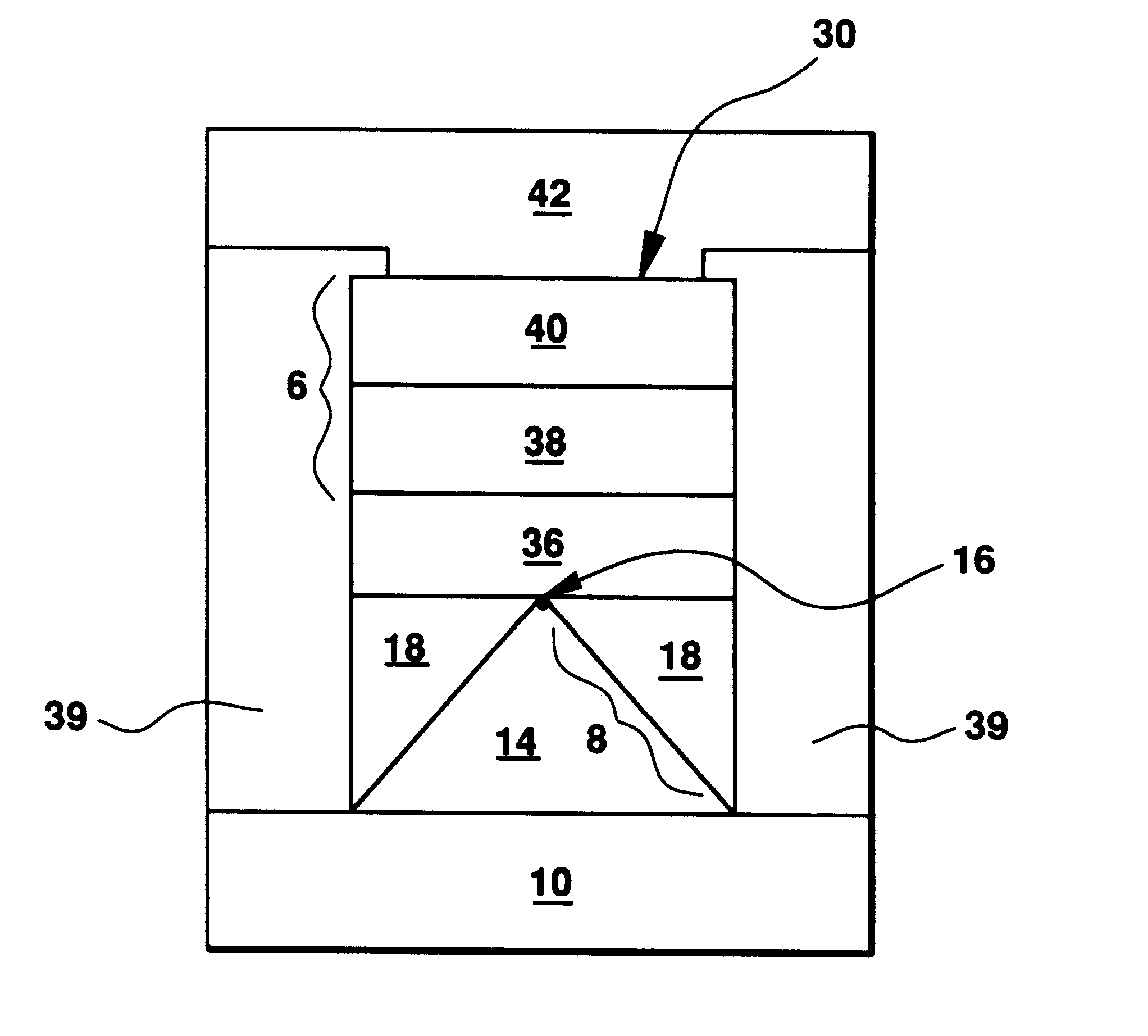

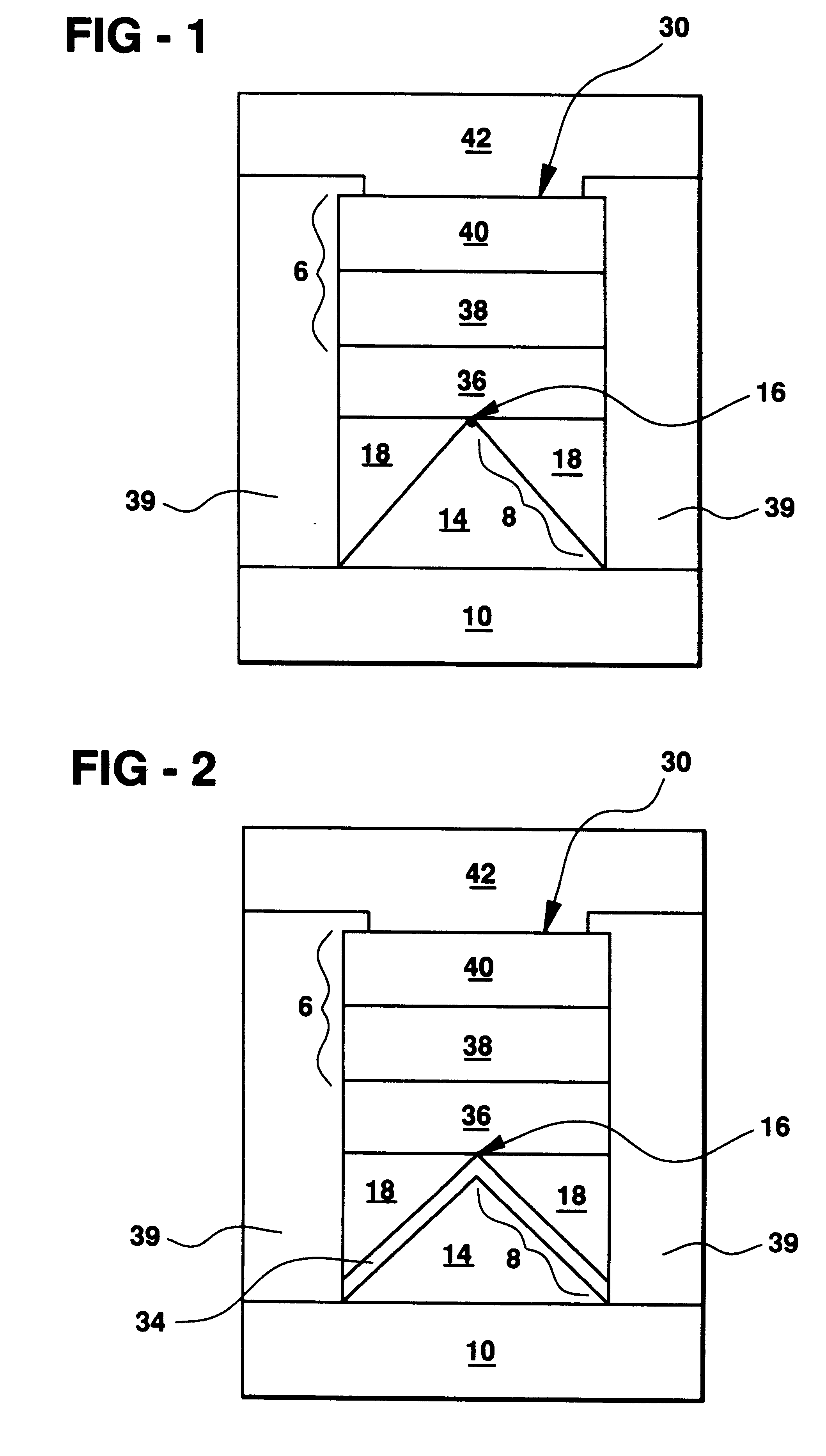

Erasable electrical memories fabricated from the broad class of chalcogenide materials have employed structural changes that were accommodated by movement of certain atomic species within the material to permit change of phase as the material switched from the amorphous state to the crystalline state. For example, in the case of electrically switchable chalcogenide alloys formed of tellurium and germanium, such as those comprising about 80% to 85% tellurium and about 15% germanium along with certain other elements in small quantities of about one to two percent each, such as sulfur and arsenic, the more ordered or crystalline state was typically characterized by the formation of a highly electrically conductive crystalline. Te filament within the switchable pore of the memory material. A typical composition of such a prior art material would be, for example, Te.sub.81 Ge.sub.15 S.sub.2 As.sub.2 or Te.sub.81 Ge.sub.15 S.sub.2 Sb.sub.2. Because Te is so highly conductive in its crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com