Marine vessel construction

a technology for marine vessels and construction, applied in the field of marine vessels, can solve the problems of stranding, collision or other accidents, ineffective withstand strong impact force, petroleum product dumping, etc., and achieve the effects of reducing impact force, low density and strength, and low density and energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

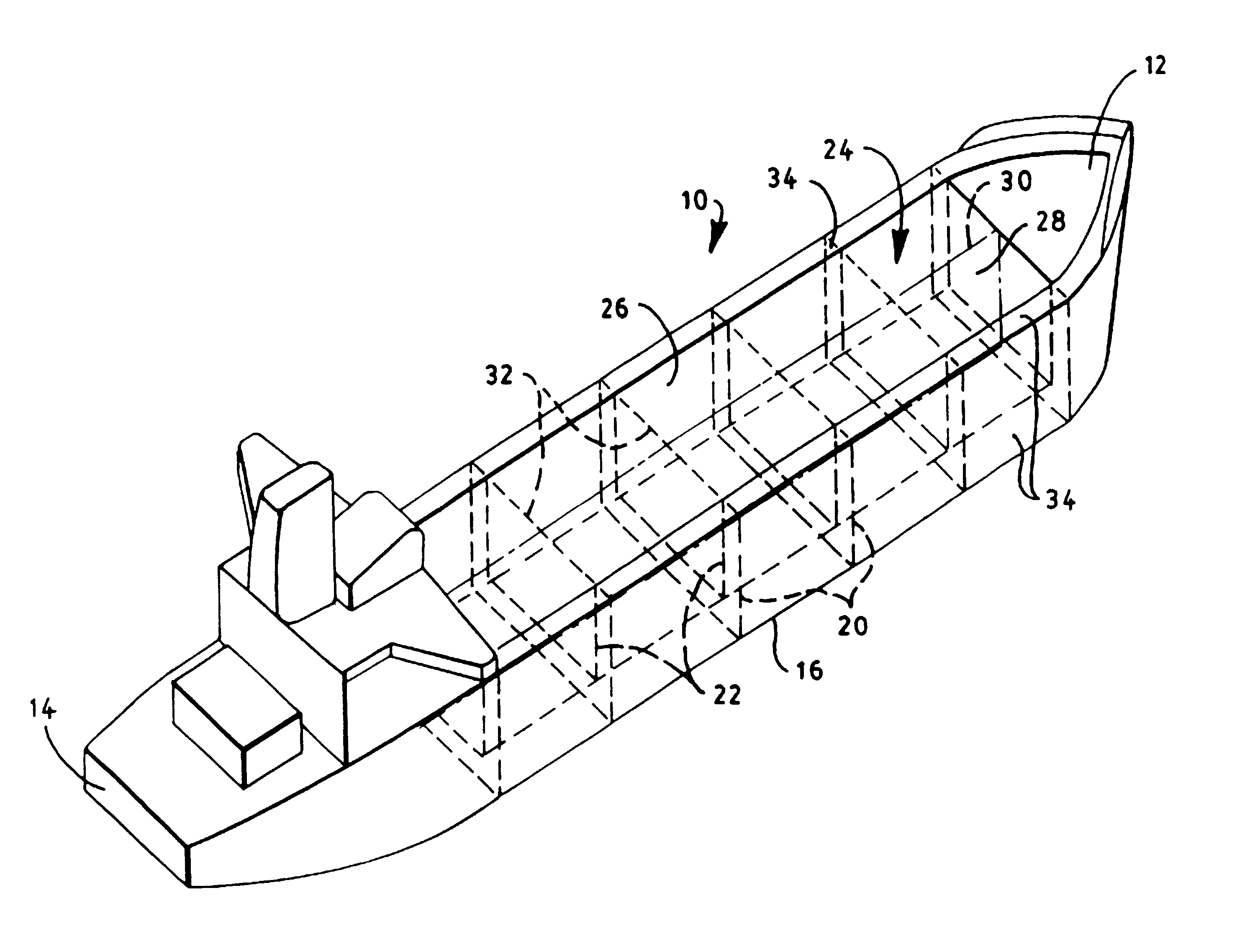

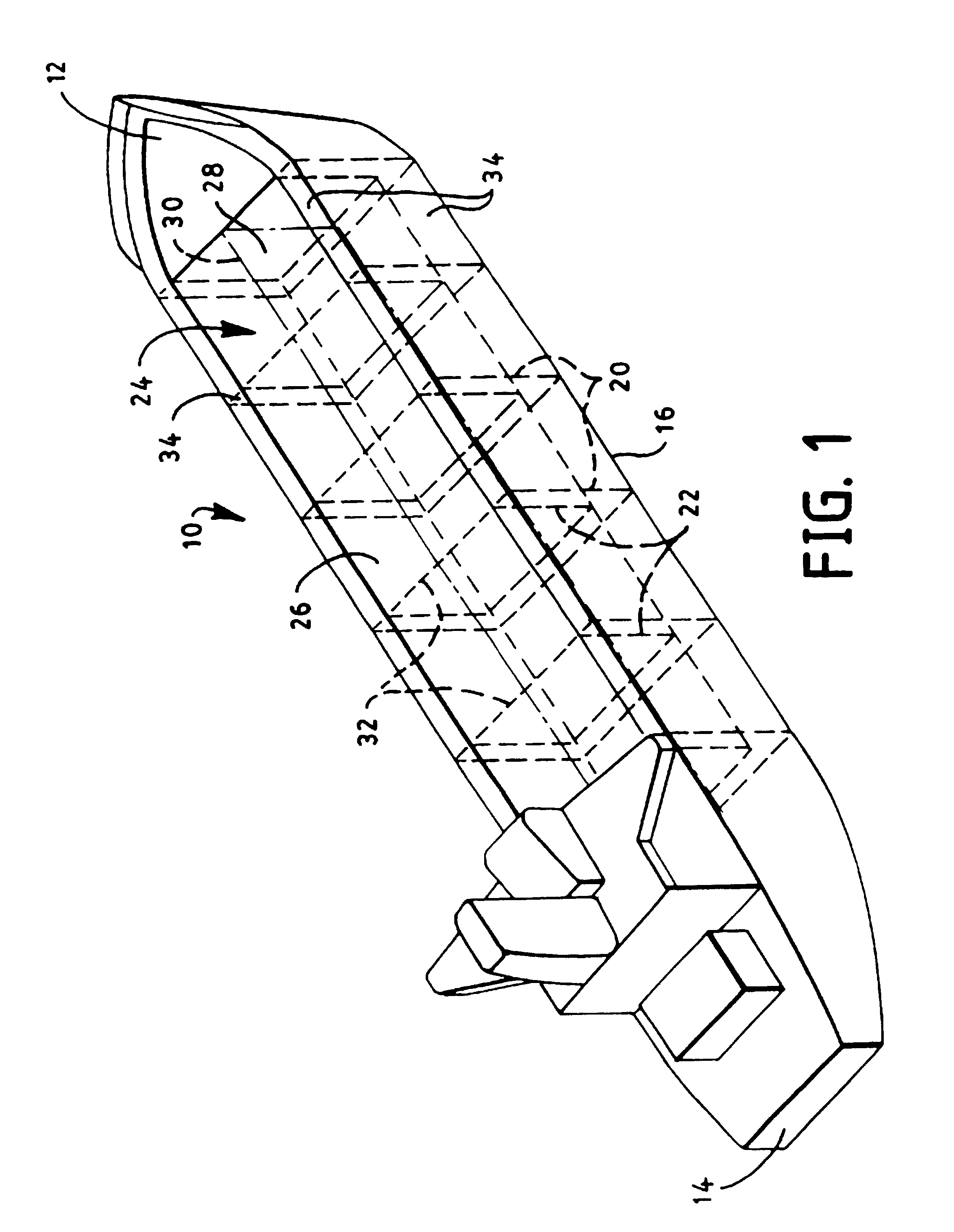

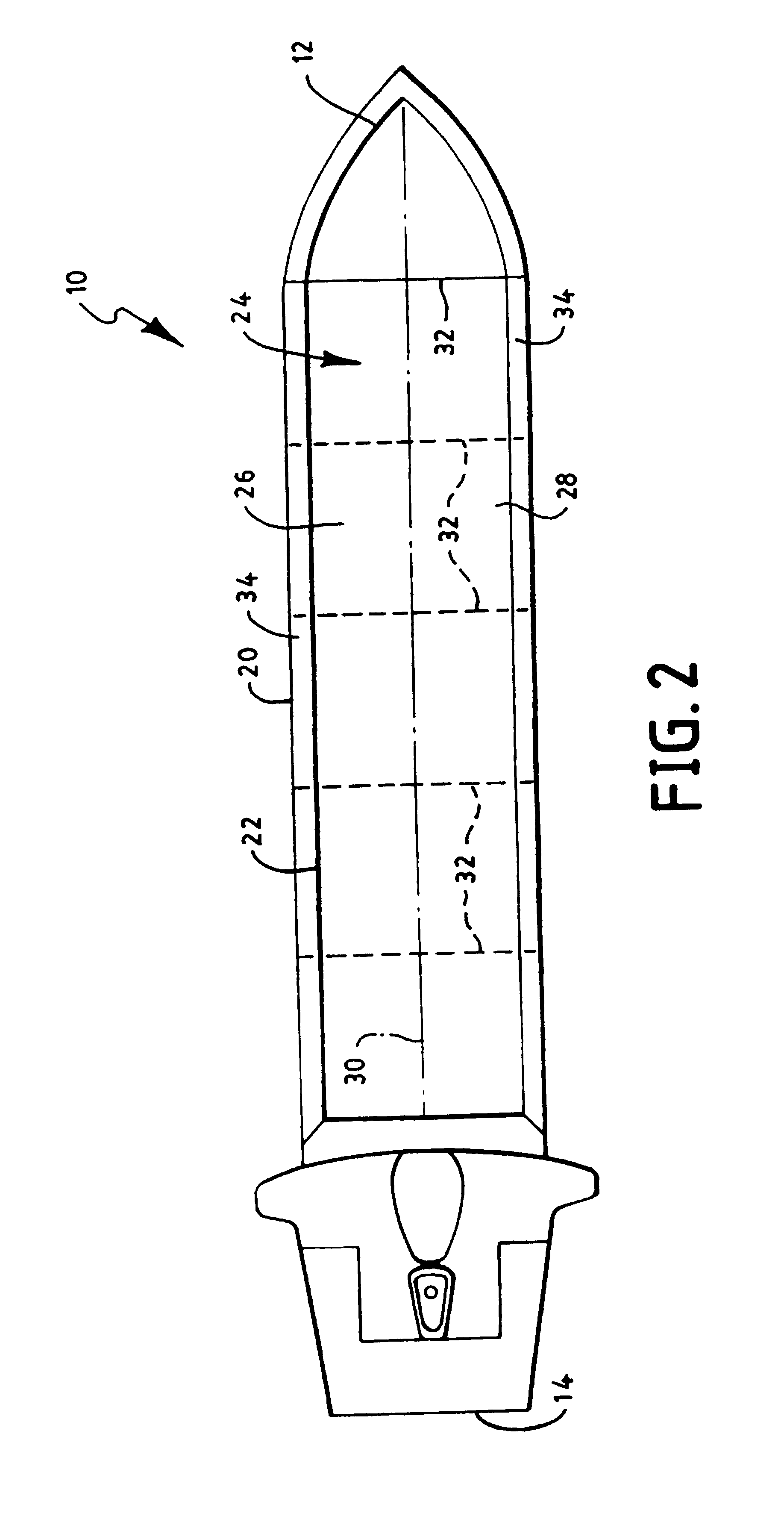

In accordance with the present invention the space between the inner hull and the outer hull of a double hull marine vessel is filled with a composition comprising a hardened syntactic foam and macrospheres. The volume percent hardened syntactic foam of the syntactic foam-macrospheres mixture is between about 10 and about 60 volume %, preferably between about 20 and about 40 volume % while the volume percent macrospheres of the mixture is between about 40 and about 90 volume %, preferably between about 60 and about 80 volume %. The macrospheres can have an essentially uniform diameter or can have a varying diameter between about {fraction (1 / 16)} and about 4 inches, preferably between about ¼ inch and about ½ inch. The macrospheres can be formed of any synthetic resin composition which may include a reinforcing agent such as fibers including glass fibers, carbon fibers or the like. The macrospheres typically are formed from thermoset or thermoplastic polymers such as polyvinyl ester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com