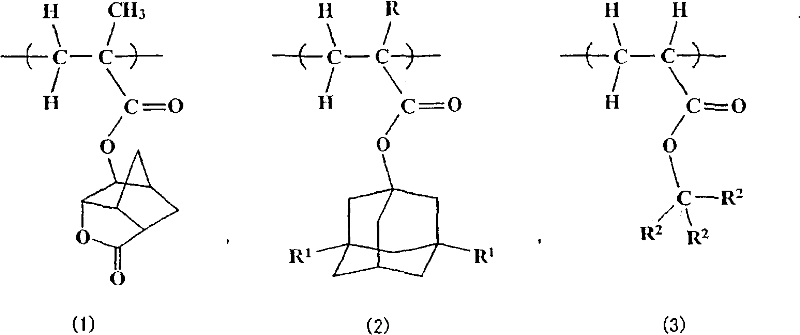

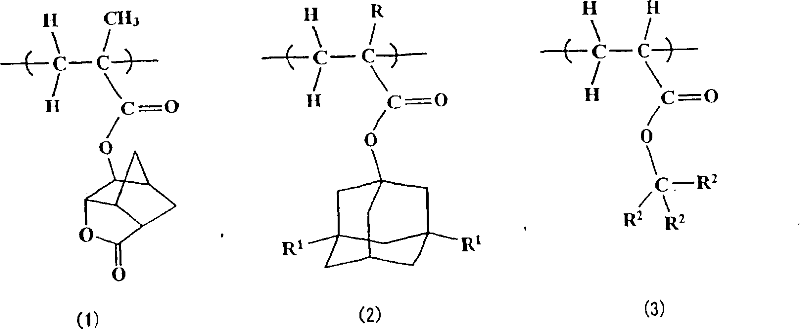

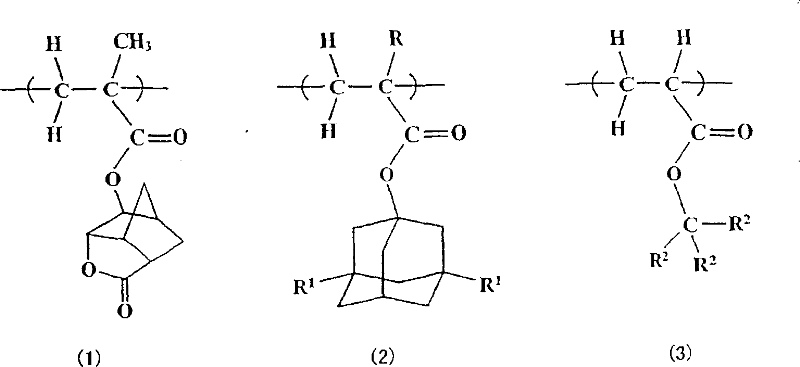

Acrylic copolymer and radiation-sensitive resin composition

A technology of resin composition and acrylic, which is applied in optics, instruments, optomechanical equipment, etc. It can solve the problems of poor resolution, no thermal deformation technology, etc., and achieve the effect of reducing line width variation and high dry spots on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107]

[0108] Prepare to dissolve 55.00 g (50 mol %) of compound (4-1), 11.70 g (10 mol %) of compound (4-2), and 33.31 g (40 mol %) of compound (4-3) in 200 g of 2-butanone 4.56 g of dimethyl azobisisobutyrate was added to the monomer solution, and a 1000 ml three-necked flask into which 100 g of 2-butanone had been added was purged with nitrogen for 30 minutes. After nitrogen purging, the reactor was heated to 80° C. while stirring, and the above-mentioned monomer solution prepared in advance was added dropwise over 4 hours using a dropping funnel. The start of the dropwise addition was regarded as the start time of the polymerization, and the polymerization reaction was carried out for 6 hours. After the polymerization is completed, the polymerization solution is cooled to below 30° C. by water cooling, poured into 2000 g of a mixed solvent of 2-propanol / n-heptane=1 / 2, and the precipitated white powder is filtered. The filtered white powder was washed twice on the slu...

Embodiment 2

[0110]

[0111] Prepare to dissolve 54.57g (50 mol%) of compound (5-1), 12.39g (10 mol%) of compound (5-2) and 33.04g (40 mol%) of compound (5-3) in 200g of 2-butanone 4.52 g of dimethyl azobisisobutyrate was added into the monomer solution, and a 1000 ml three-neck flask into which 100 g of 2-butanone had been added was purged with nitrogen for 30 minutes. After nitrogen purging, the reactor was heated to 80° C. while stirring, and the above-mentioned monomer solution prepared in advance was added dropwise over 4 hours using a dropping funnel. The start of the dropwise addition was regarded as the start time of the polymerization, and the polymerization reaction was carried out for 6 hours. After the polymerization is completed, the polymerization solution is cooled to below 30° C. by water cooling, put into 2000 g of a mixed solvent of 2-propanol / n-heptane=1 / 2, and the precipitated white powder is filtered. Use the mixed solvent 400g of 2-propanol / n-heptane=1 / 2 to wash t...

Embodiment 3

[0113]

[0114] Prepare to dissolve 55.38g (50 mol%) of compound (6-1), 11.08g (10 mol%) of compound (6-2) and 33.54g (40 mol%) of compound (6-3) in 200g of 2-butanone 4.59 g of dimethyl azobisisobutyrate was added into the monomer solution, and a 1000 ml three-necked flask into which 100 g of 2-butanone had been added was purged with nitrogen for 30 minutes. After nitrogen purging, the reactor was heated to 80° C. while stirring, and the above-mentioned monomer solution prepared in advance was added dropwise over 4 hours using a titration funnel. The start of the dropwise addition was regarded as the start time of the polymerization, and the polymerization reaction was carried out for 6 hours. After the polymerization is completed, the polymerization solution is cooled to below 30° C. by water cooling, poured into 2000 g of a mixed solvent of 2-propanol / n-heptane=1 / 2, and the precipitated white powder is filtered. Use the mixed solvent 400g of 2-propanol / n-heptane=1 / 2 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com