Method for producing aurantin by liquid-state fermentation of monacolin

A technology for liquid fermentation and monascus pigment, which is applied in the fields of bioengineering and pigment preparation, and can solve the problems of not achieving large-scale production and insufficient development and research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

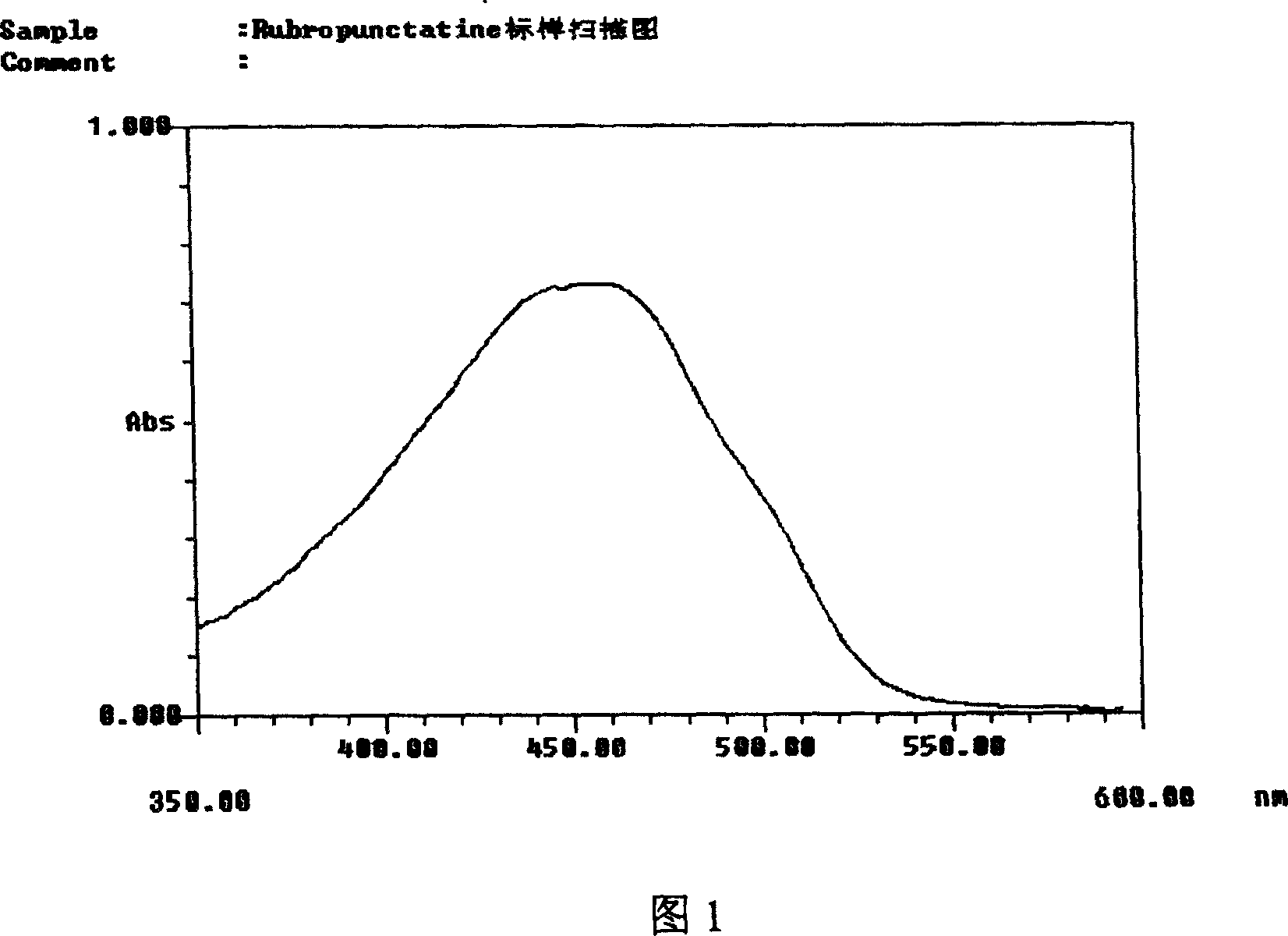

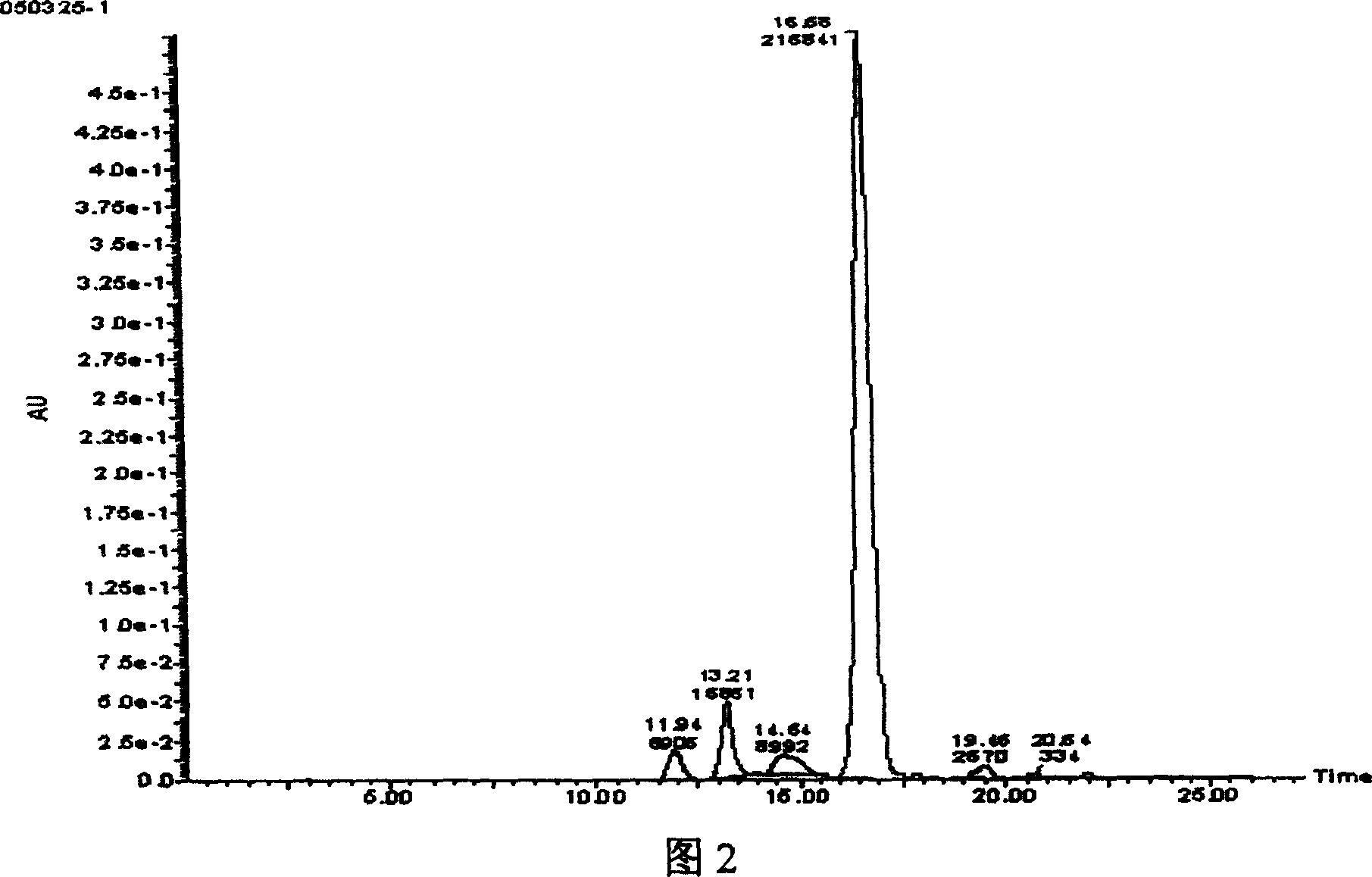

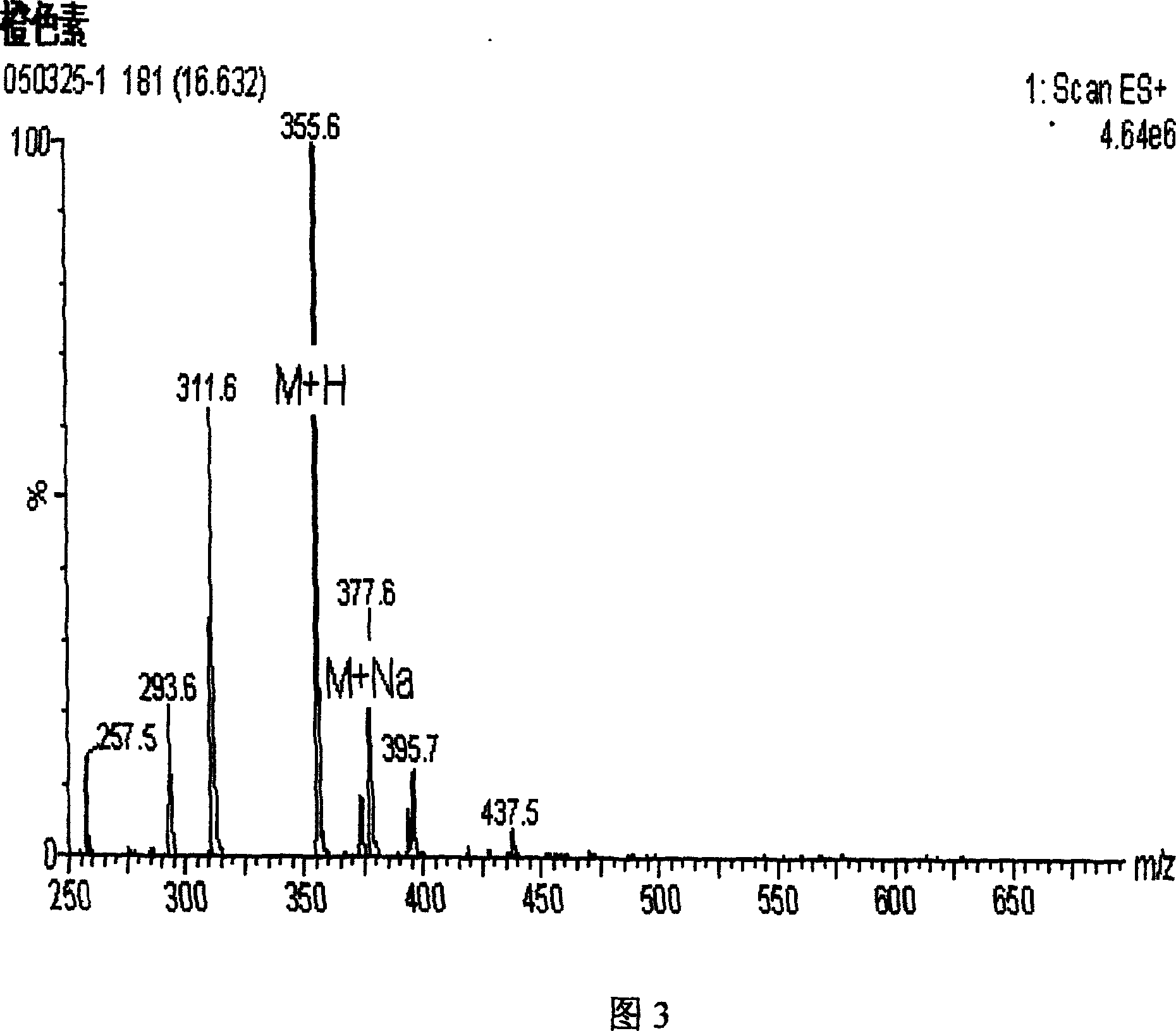

Image

Examples

Embodiment 1

[0029] Example 1. Culture medium optimization

[0030] The effect of carbon source on the production of orange pigment

[0031] Glucose, sucrose, corn starch, glutinous rice flour, maltose and dextrin were selected as carbon sources for experiments. The carbon source concentration is 50g / L, and the other proportions of the medium can be found in the basic fermentation medium. When cornstarch was used as the carbon source for the fermentation of 9903 strains, the color value of orange pigment and the amount of bacteria were much higher than when other carbon sources were used, indicating that cornstarch may not only contribute to the growth of bacteria, but more importantly The most important thing is to play a positive role in the synthesis of the secondary metabolite of orange pigment. The effect of corn starch may be that the composition of corn starch is more complex, and it contains more inorganic or organic components. For Monascus The nutrients are more complete, which...

Embodiment 2

[0048] Embodiment 2. Optimization of fermentation conditions

[0049] Optimization of fermentation parameters

[0050] Using the optimum medium formulation obtained from the orthogonal experiment in Example 1, the operating conditions for submerged culture in a 15L fermenter were optimized. Monascus liquid fermentation is an aerobic fermentation, so the dissolved oxygen level is an important parameter, which directly affects the yield of fermentation products, especially the secondary metabolite orange pigment. By changing the ventilation rate and the stirring speed to form two different levels of dissolved oxygen conditions, high and low, to investigate the production of orange pigment by Monascus under these two different dissolved oxygen conditions, it was found that under the condition of low dissolved oxygen, the orange pigment produced The highest peak time of koji significantly lags behind that of high dissolved oxygen, and the final yield of orange pigment is also sig...

Embodiment 3

[0056] Example 3. Extraction and refining of orange pigment

[0057] Production of Orange Pigment by Direct Spray Drying

[0058] Through experimental research, the operating process parameter conditions for the orange pigment fermentation liquid to be directly spray-dried are determined: the fermentation liquid is homogenized under high pressure, and the pressure is 3kgf / cm 2 , or colloid mill to crush the bacteria, add dextrin as an auxiliary desiccant, the amount of dextrin added is: dextrin: fermentation broth is 0.02-0.06 in Kg / L, the air inlet temperature is 170-200 °C, and the outlet temperature is 70 ~100℃, nozzle pressure 1~4kgf / cm 2 , flow rate 80 ~ 120mL / h. Under these operating conditions, the orange pigment product (I) was finally obtained, with a color value of 1030.75 U / g, a hue of 1.99, and a pigment yield of 66.67%.

[0059] Concentrated crystallization and spray drying of orange pigment.

[0060] Comparison of Extraction Effects of Monascus Orange Pigment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com