Ganoderrma tsugae-proteoglycan and its preparing method and use

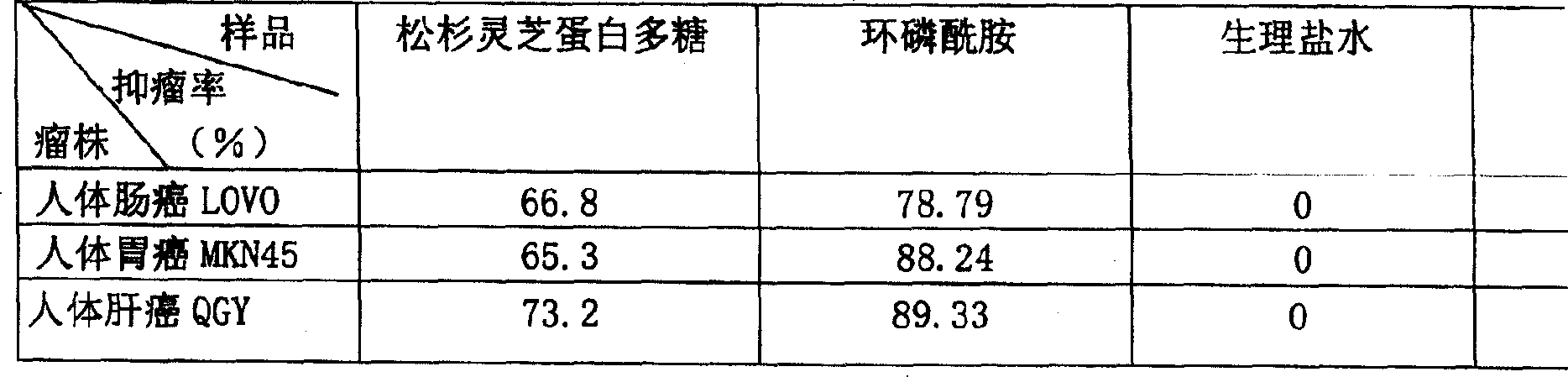

A technology of proteoglycan, pine fir and Ganoderma lucidum, applied in the application of active ingredients, proteoglycan and its extraction field, to achieve the effect of high purity, high tumor inhibition rate and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, preparation pine fir Ganoderma lucidum protein-polysaccharide

[0021] Weigh 100 grams of pine fir ganoderma fruiting body powder, add 1 liter of 85% ethanol, heat and reflux at 75°C for 2 hours, repeat 3 times, filter, add 2 liters of deionized water to the medicinal residue, heat to boil, stir at intervals, each time Extract for 3 hours, repeat 5 times, filter, combine extracts, concentrate to a volume of 0.5-1 liter, cool to room temperature, add 2.5 liters of absolute ethanol, stir while adding, place at 4°C for clarification, centrifuge (7000-8000rpm, 15min), take the precipitate and dissolve it in water, microfilter at 10μm and 1μm, take the filtrate, then ultrafilter it through 80KD, take the filtrate, and then use a 3KD membrane for ultrafiltration, and the obtained retentate is dissolved in deionized water and balanced on the surface DEAE-Cellulose (Cl - ) column (3 × 75cm), the loading flow rate is 0.25ml / min, then deionized water is used as the...

Embodiment 2

[0022] Embodiment 2, preparation of Pinus fir Ganoderma lucidum protein-polysaccharide

[0023]Weigh 100 grams of pine fir ganoderma fruiting body powder, add 1.5 liters of 80% methanol, heat and reflux at 80°C for 3 hours, repeat 5 times, filter, add 4 liters of deionized water to the medicinal residue, heat to boil, stir at intervals, each time Extract for 3 hours, repeat 6 times, filter, combine the filtrates, concentrate to a volume of 1 liter, cool, add 4 liters of anhydrous methanol, stir while adding, place at 4°C for clarification, centrifuge (8000rpm, 15min), the precipitate is dissolved in water, After 10 μm, 5 μm and 1 μm microfiltration, take the filtrate and pass it through an ultrafiltration membrane of 80KD, take the filtrate, and then use a 3KD membrane for ultrafiltration, and the obtained retentate is dissolved in deionized water, and put on a well-balanced Sepharose-CL6B column (3× 70cm), the sample loading flow rate is 0.6ml / min, then use deionized water as...

Embodiment 3

[0024] Example 3, Preparation of Pinus fir Ganoderma lucidum protein-polysaccharide

[0025] Weigh 50kg of pine, fir, ganoderma fruiting body powder into an extraction tank, add 450 liters of 85% ethanol, under stirring, reflux extraction at 75-80°C for 2 hours each time, repeat 3 times, recover ethanol, add water to 1000 liters of dregs , heated to 100°C, extracted for 3 hours, repeated 5 times, filtered, combined the filtrates, concentrated to a volume of 250 liters, added 5 times the volume of absolute ethanol under stirring, placed at a low temperature of 4°C, clarified, centrifuged (8000rpm, 15min), the precipitate was dissolved in deionized water, passed through 10μm microfiltration, 1μm microfiltration, and then 80KD ultrafiltration, then concentrated with a 3KD membrane, and the obtained retentate was dissolved in deionized water, and the balanced DEAE-Sepharose (F.F.) column (3×80cm), the sample loading flow rate is 0.4ml / min, then use deionized water as the mobile ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com