Method for forming an oxynitride spacer for a metal gate electrode using a PECVD process with a silicon-starving atmosphere

A metal gate and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as low conductivity, poor conductivity, offset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

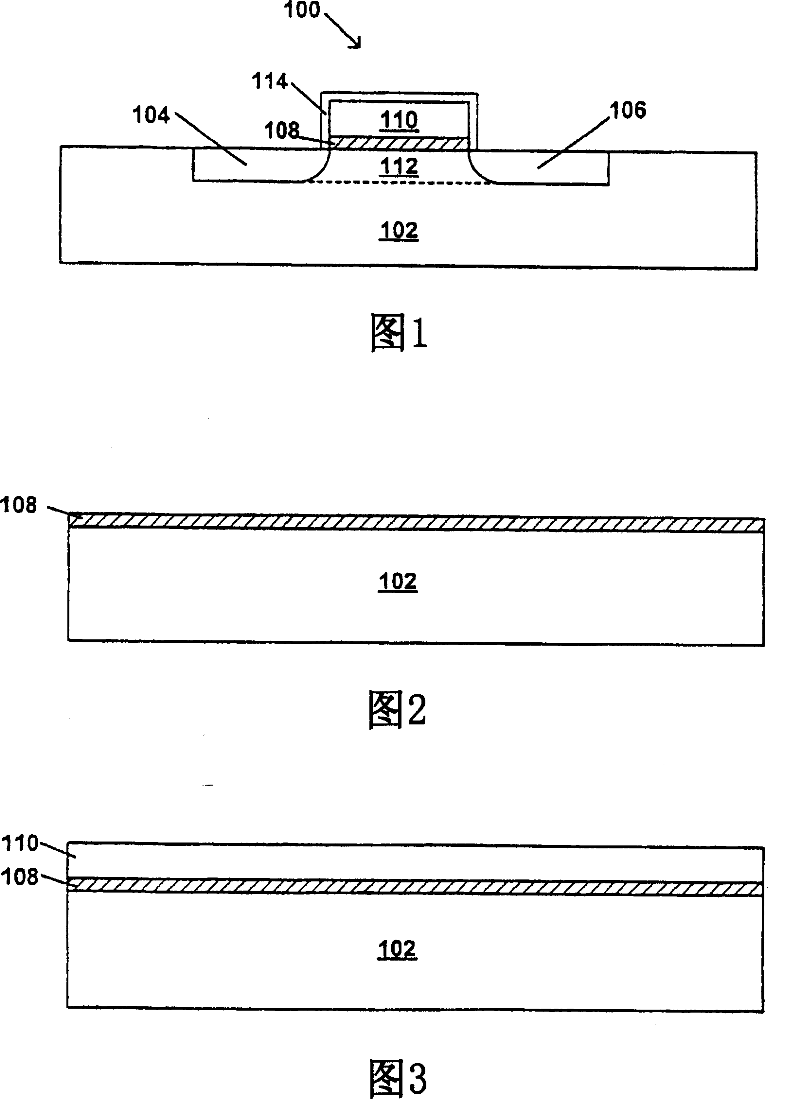

[0017] The term "metal gate" or "metal gate electrode" as used herein refers to the gate or any other Metal structures made of, for example, molybdenum (Mo), nickel (Ni), tantalum (Ta), aluminum (Al), cobalt (Co), copper (Cu), rhenium (Re), titanium (Ti) or tungsten (W) Or a mixture or alloy of two or more metals. The metal may also comprise more than one of tantalum nitride (TaN), tantalum silicon nitride (TaSiN), tungsten nitride (WN), tungsten silicon nitride (WSiN), and similar conductive nitrides of the foregoing metals. As described herein, the metal gate electrode is formed using any method known in the art of fabricating such structures. It should be recognized that although the invention is described herein in terms of a metal gate electrode, the invention is not so limited but extends the scope of the invention to the formation of oxynitrides thereon that reduce or avoid silicide formation. Any metallic structure over a silicon layer.

[0018] The term "silicon ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com