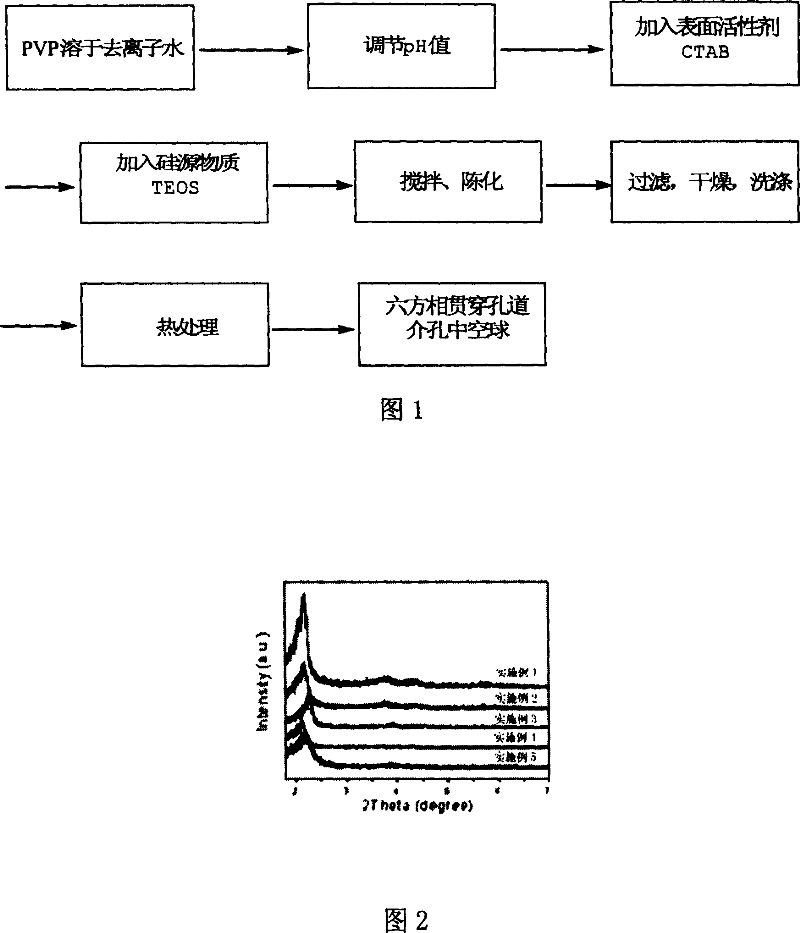

Process for preparing silicon dioxide hollow ball material with hexagonal phase penetrating mesopore orbit

A technology of silica and hexagonal phase, applied in the direction of silica, etc., can solve the problem that the guest molecules cannot be transported inside and outside, and achieve the effect of simple preparation process, good dispersion and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Co-surfactant is polyvinylpyrrolidone (PVP, k 30 ); Silicon source is tetraethyl orthosilicate, Si(OC 2 h 5 ) 4 ; The surfactant is cetyltrimethylammonium bromide CTAB; the pH value of the solution is adjusted with sodium hydroxide. According to the formula ratio (mass ratio): 0.5PVP: 0.7CTAB: 0.23NaOH: 2.6TEOS: 60H 2 O was added to various reaction substances, stirred, aged, filtered, washed with deionized water and ethanol for several times, dried at 100°C for 12 hours, and finally calcined at 550°C for 6 hours to remove the surfactant.

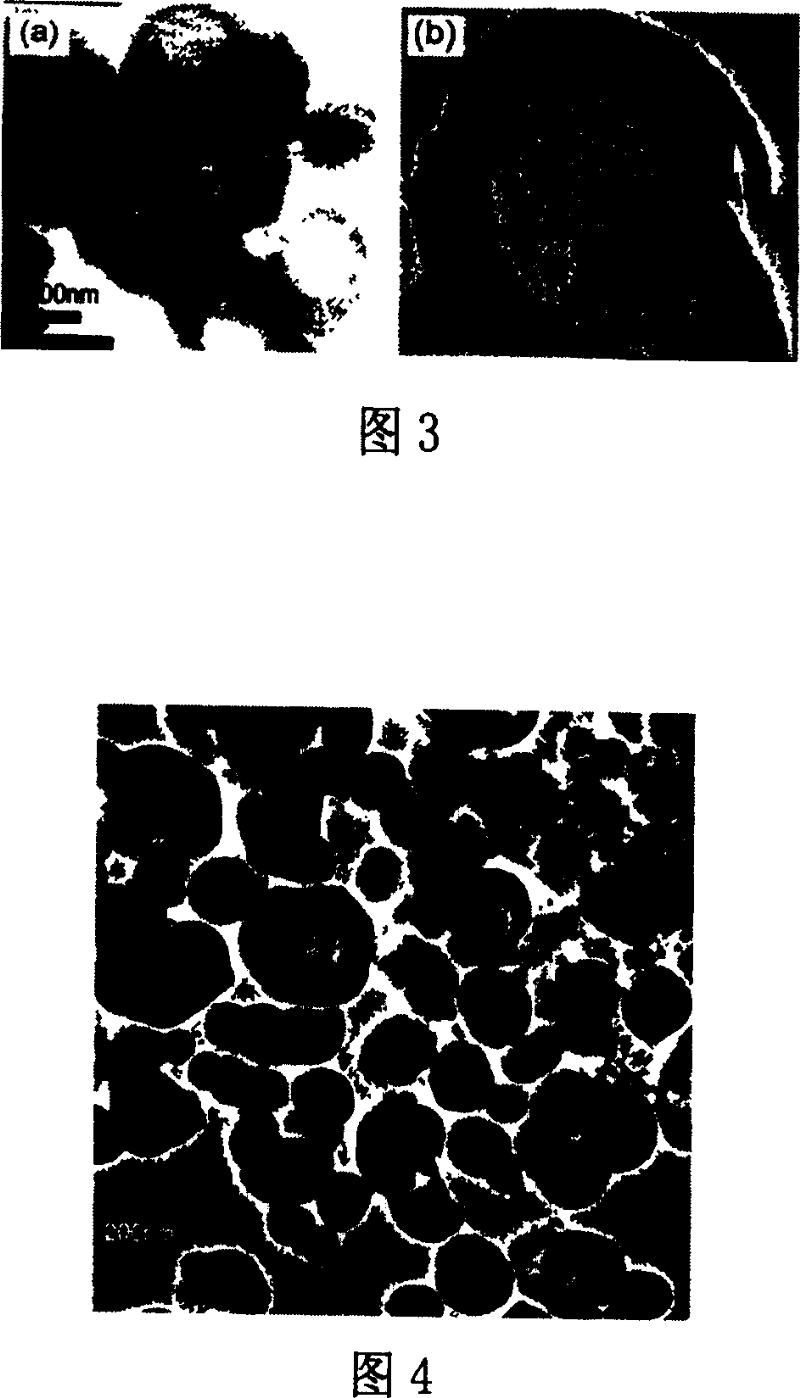

[0024] Its small-angle X-ray diffraction results are shown in curve 1 in Figure 2; its low-power and high-power transmission electron microscope photos are shown in Figure 3a and b, and its product is a mesoporous hollow sphere with a through-hole channel, and the size of the hollow sphere is 300-400nm , the size of the hollow core is about 200nm. It can be seen that this method can obtain silica mesoporous hollow spheres with h...

Embodiment 2-5

[0025] Embodiment 2-5 basic reaction substance type is constant, only changes the add-on of various reaction substances, obtains following several different implementation modes:

Embodiment 2

[0027] Formula ratio: 0.25PVP: 0.7CTAB: 0.23NaOH: 2.6TEOS: 60H 2 O, its small-angle X-ray diffraction pattern is shown in curve 2 in Figure 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com