Equipment of desulfurizing fume by alkalifying method, through dissolved in cold water and electrolysis of removing hard water

A technology of hard alkali addition and desulfurization device, applied in the gas field, can solve the problems of high cost and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

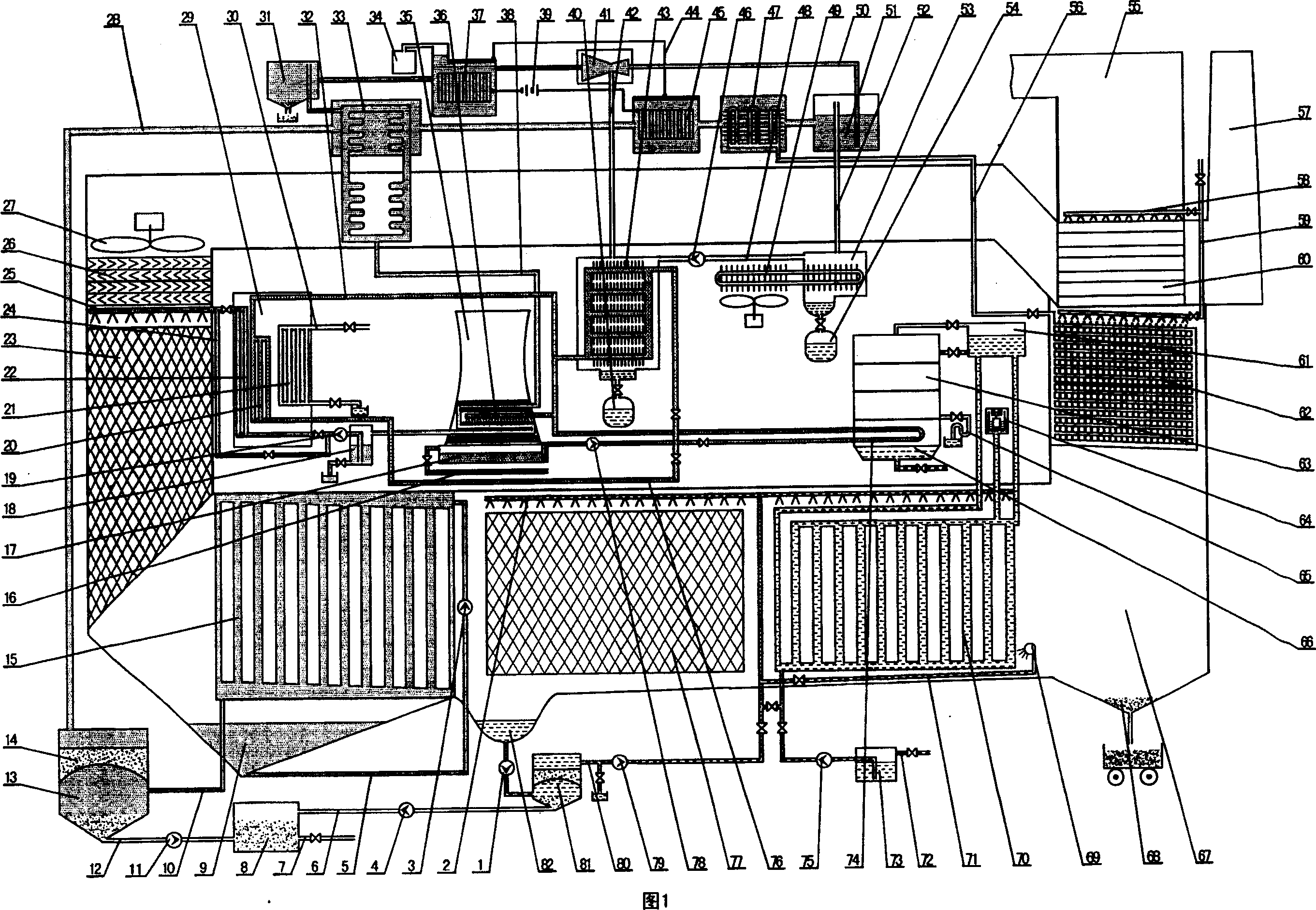

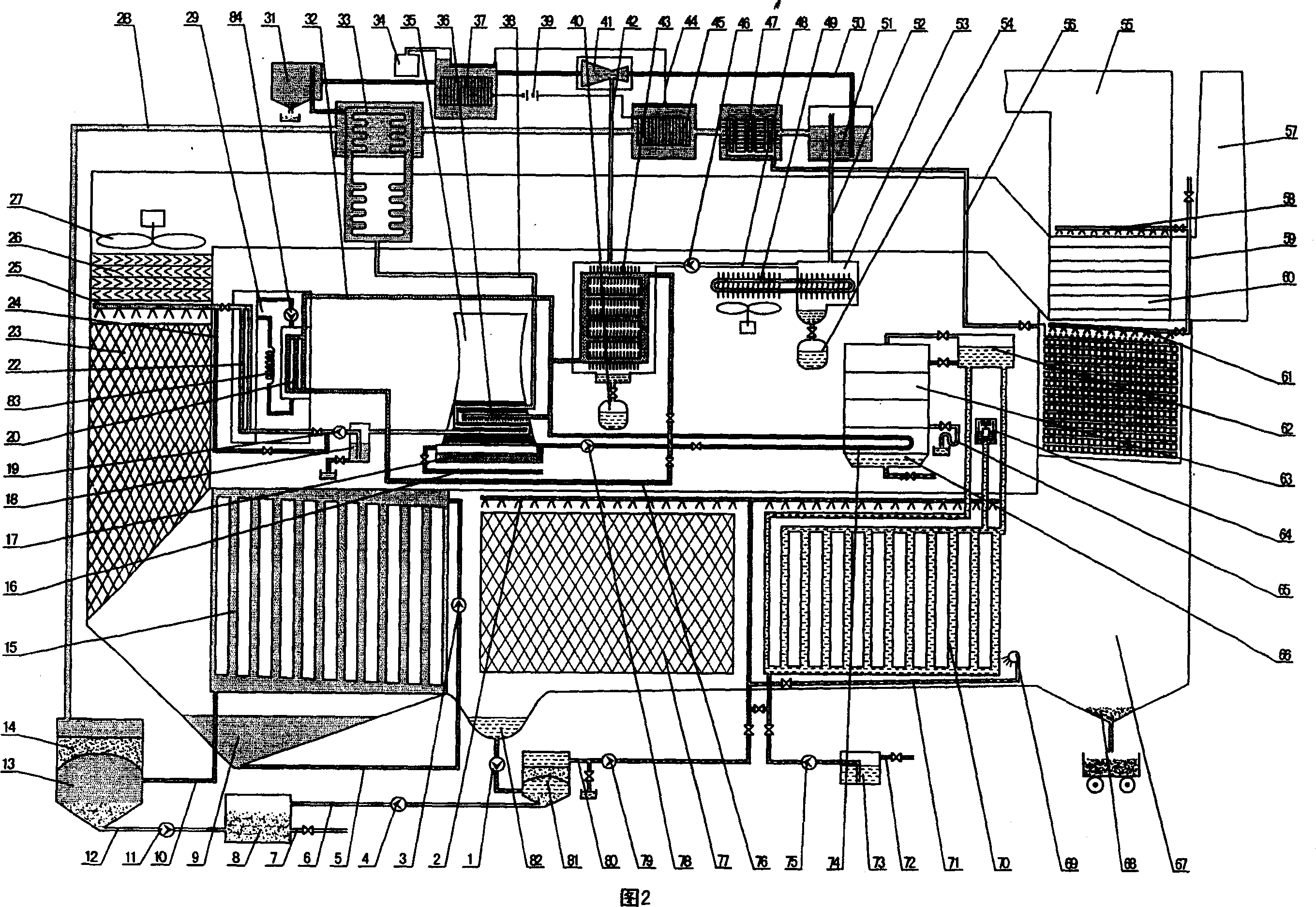

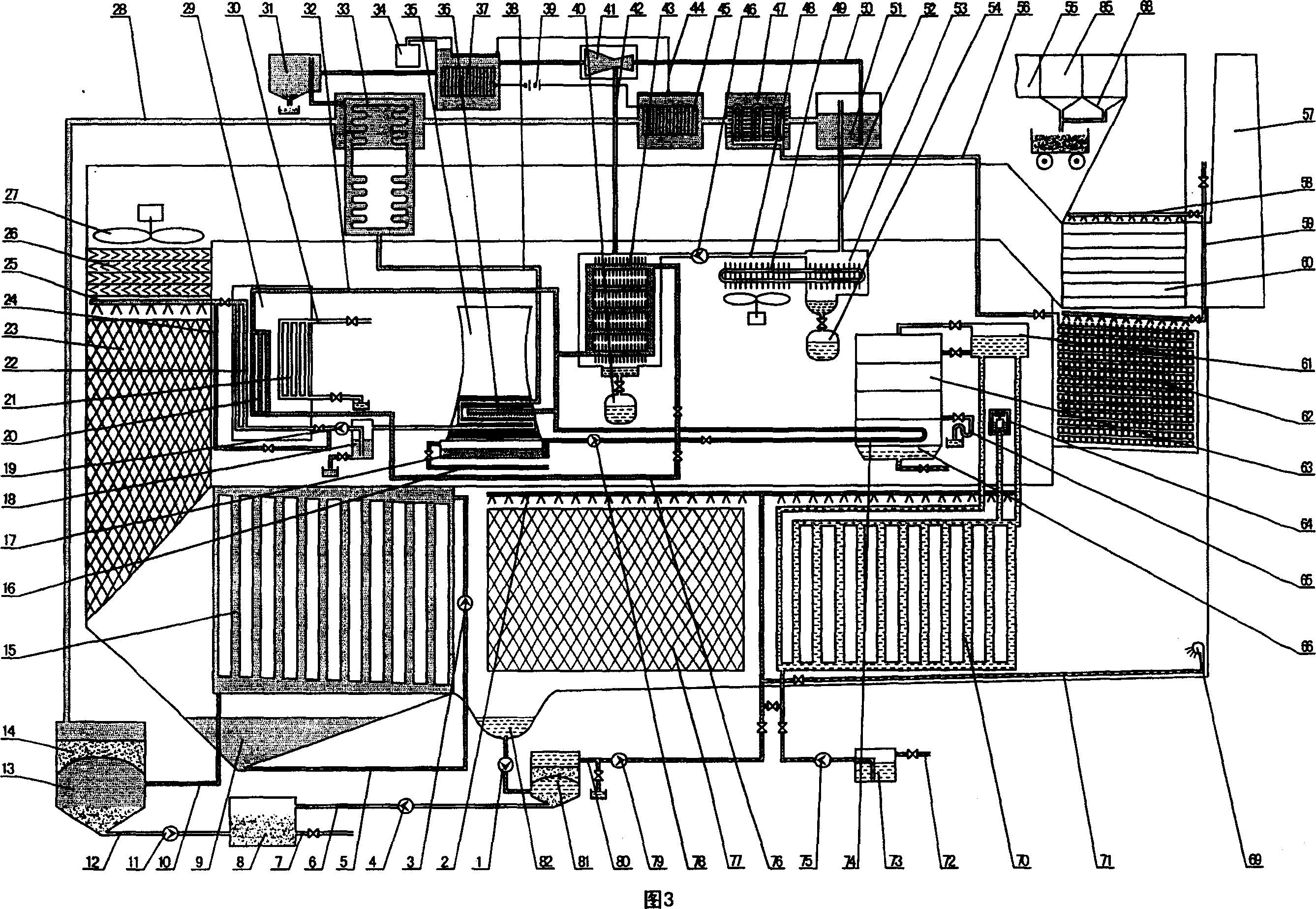

[0077] As shown in Figure 1: through the flue 55, the flue gas is introduced into the flue gas heat exchanger 60, the heat pipe evaporator 62, the expander 67, and the thermosiphon smoke gas heating evaporator 70 to exchange heat and cool down the flue gas, so that the flue gas The water vapor exothermicly condenses, dew condensation atomizes, the acid gas in the flue gas forms an acid solution, and the acid solution reacts with the alkaline dust in the flue gas to form a salt mixture, which expands the flue gas and reduces the flue gas Flow rate, so that the dust in the flue gas settles, the flue gas is introduced into the spray washing dust collector 77, the flue gas is washed and dedusted, the flue gas is introduced into the water-cooled flue gas device 15, the flue gas is further cooled, and the flue gas is introduced into cold water for dissolution The flue gas desulfurizer 23 uses the cold water sprayed by the cold water sprayer 25 to dissolve the sulfur dioxide gas in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com