Direct write-in method and apparatus of parallel laser based on harmonic resonance method

A laser direct, harmonic resonance technology, applied in photoplate-making process exposure devices, microlithography exposure equipment, electrical components, etc. The problem of low utilization rate of light in the zone plate can reduce the difficulty of production, optimize the width and number of annular bands, and reduce the difficulty of control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the parallel laser direct writing method and device based on the harmonic resonance method of the present invention will be described in detail below with reference to the accompanying drawings.

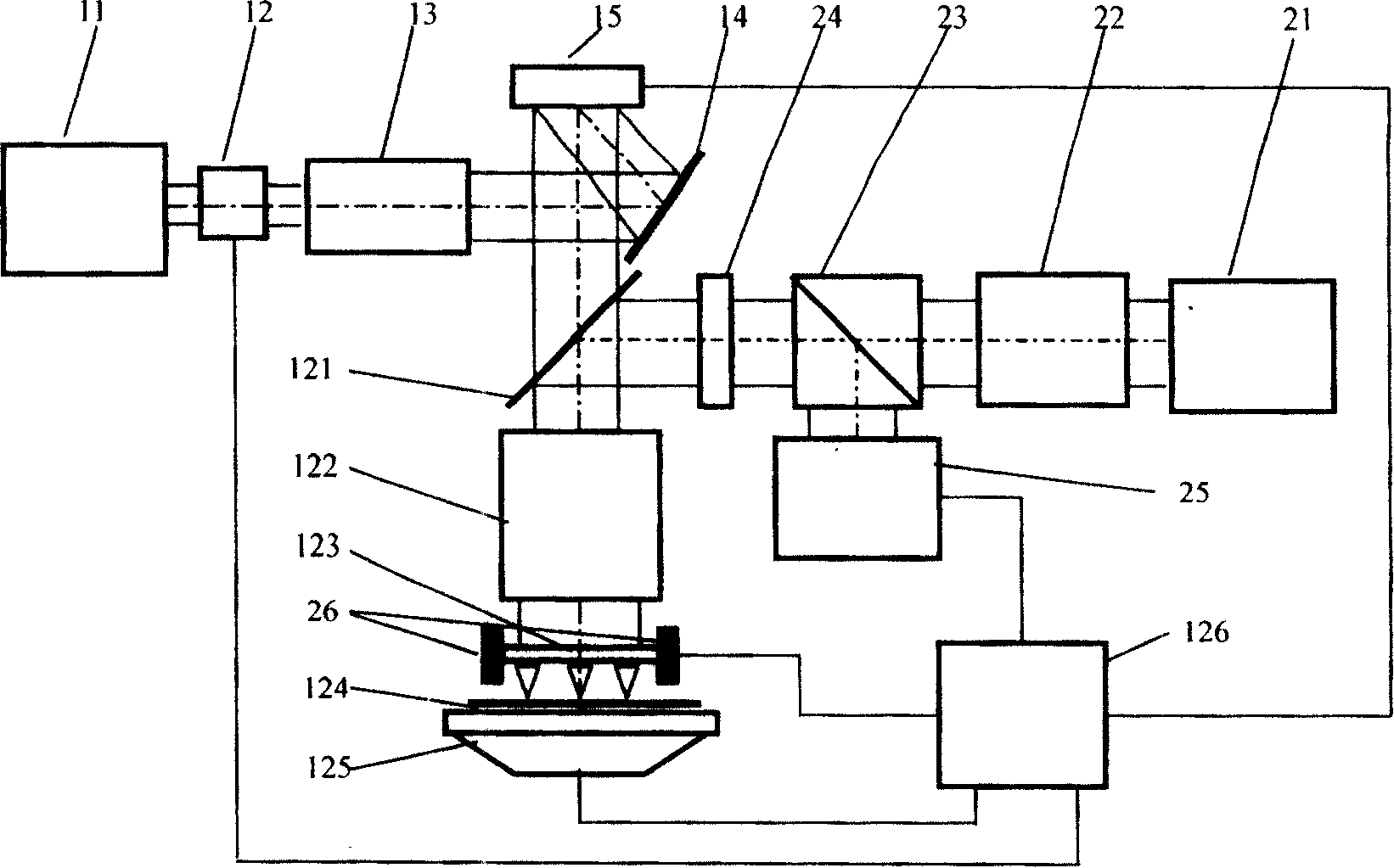

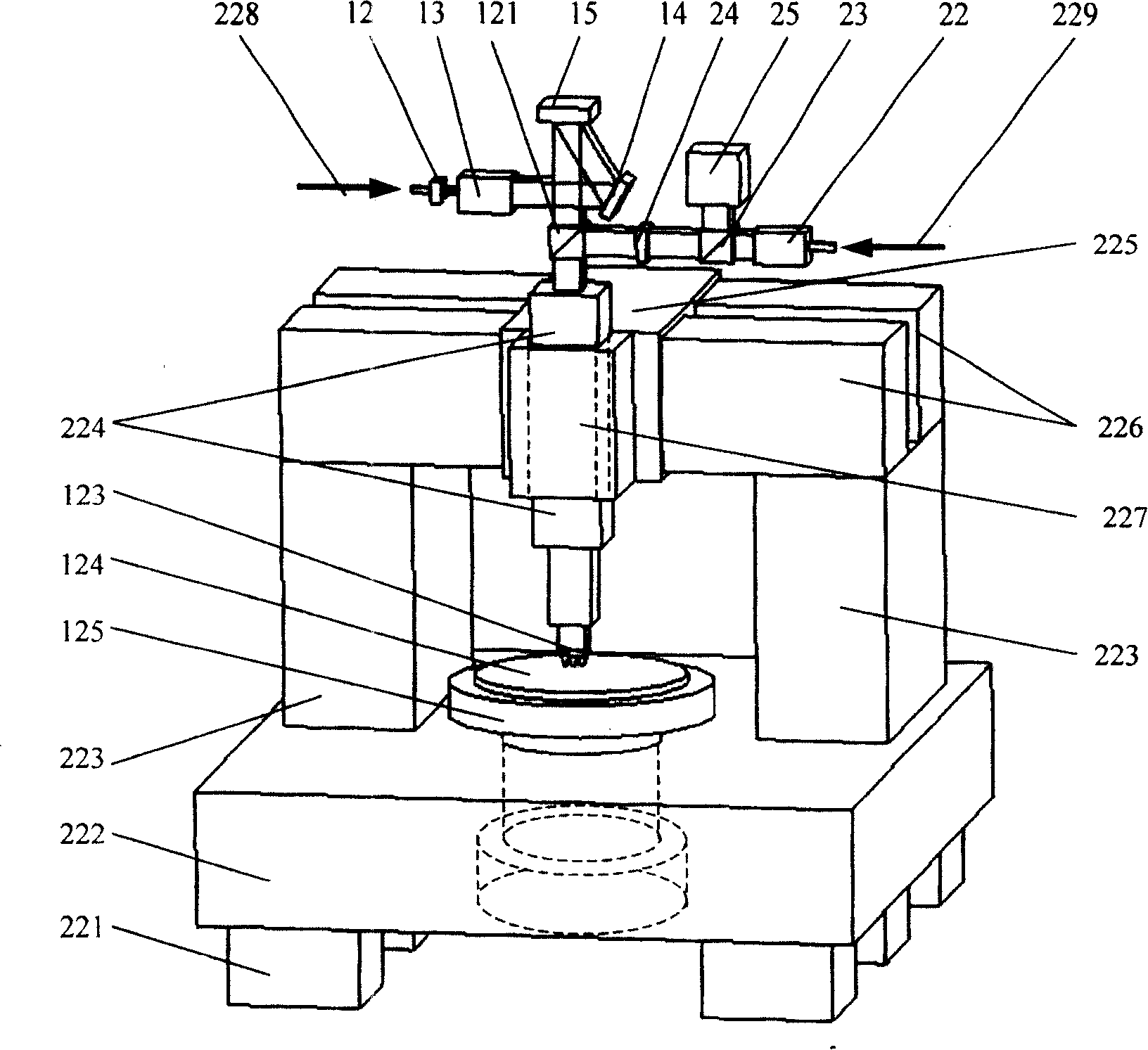

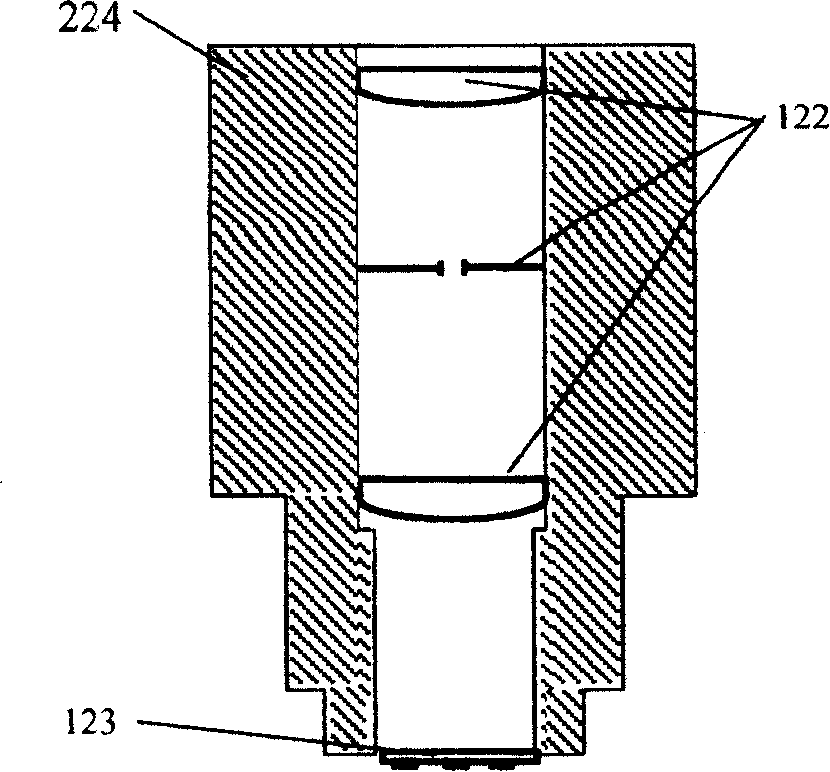

[0026] Such as figure 1 As shown, the device of the present invention includes: a writing laser 11, and an acousto-optic modulator 12, a collimating beam expander system 13, a mirror 14, and an acousto-optic modulator 12 arranged at the emitting end of the writing laser 11 in sequence, placed on the reflection optical path of the mirror 14 The spatial light modulator 15, the projection filter system 122 placed on the central axis of the reflective end of the spatial light modulator 15, the exposure substrate 124, the writing laser system composed of the substrate workbench 125 and the focus laser 21, and sequentially The collimating beam expander system 22 placed at the emission end of the focus inspection laser 21, the polarization beam splitter prism 23, the λ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com