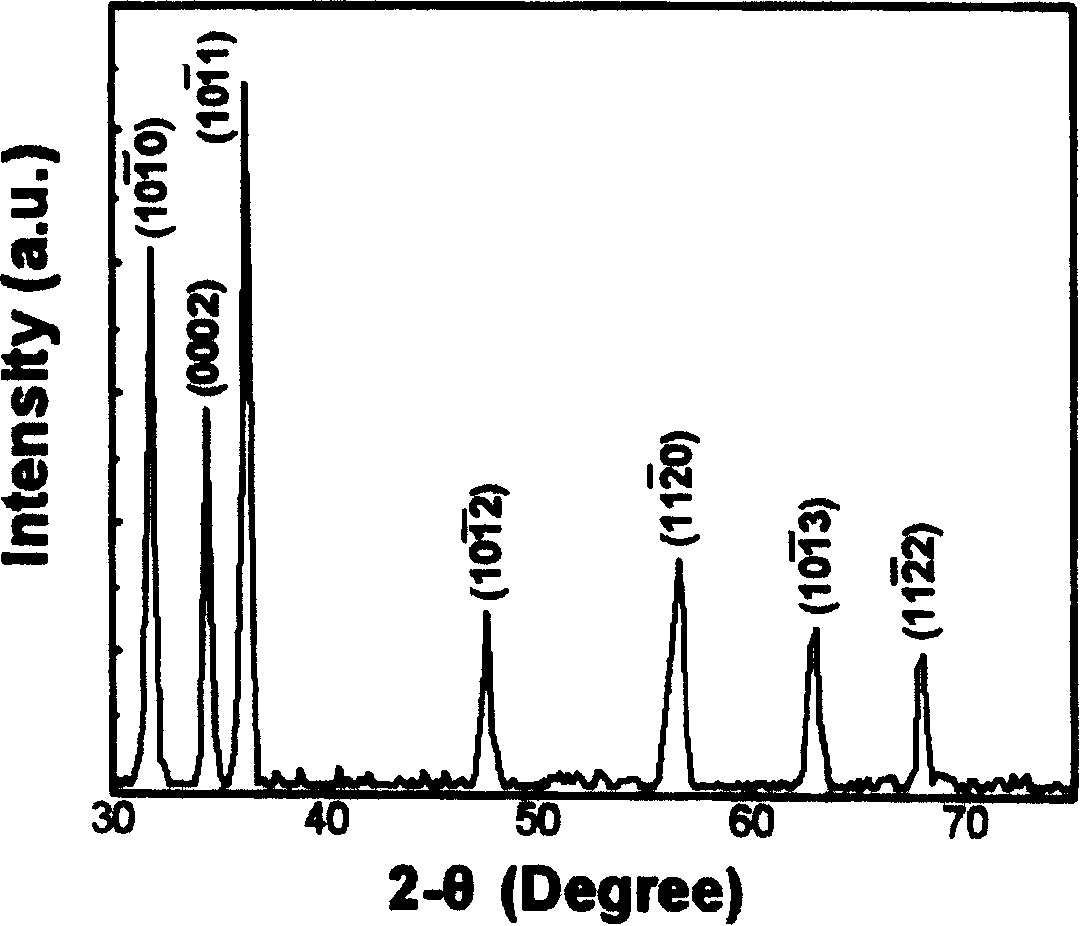

Method of growing nano-rod shaped zinc oxide by hydrothermal decomposition

A technology of nano-rods and zinc oxide, which is applied in the field of preparation of nano-scale zinc oxide, can solve the problems of high reaction temperature, complex equipment, and high cost of gas-phase methods, and achieve the effects of reducing ion types, reducing preparation costs, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. The selection and treatment of the substrate: first scrub the broad strip of copper substrate with acetone, and then use acetone and deionized water for ultrasonic cleaning for 15 minutes each;

[0022] 2. Preparation of thin film growth solution: 3ml of concentrated ammonia water with a mass ratio of 25% was added dropwise to 40ml of 0.12M zinc chloride solution and fully stirred; the solution was placed in a glass bottle with a screw cap.

[0023] 3. Treatment of thin film growth solution: airtight the above solution and treat it with ultrasound for 25 minutes;

[0024] 4. Insert the cleaned copper substrate diagonally into the solution and seal the solution again. The closed container was immediately placed in an oven at 94° C. and allowed to stand for 60 minutes. Take the substrate out and rinse with deionized water and let it dry naturally. Finally, densely arranged tower-shaped zinc oxide nanostructures can be obtained on the lower side of the substrate.

[0025] ...

Embodiment 2

[0028] 1. Substrate selection and treatment: first scrub the wide strip of stainless steel substrate with acetone, and then use acetone and deionized water to ultrasonically clean each for 15 minutes;

[0029] 2. Preparation of thin film growth solution: drop 2.5ml of concentrated ammonia water with a mass ratio of 25% into 40ml of 0.12M zinc chloride solution and fully stir; the solution is placed in a glass bottle with a screw cap.

[0030] 3. Treatment of thin film growth solution: airtight the above solution and treat it with ultrasound for 35 minutes;

[0031] 4. Insert the cleaned stainless steel sheet substrate obliquely into the solution and seal the solution again. Immediately afterwards, the closed container was placed in an oven at 96° C. and allowed to stand for 70 minutes. Take the substrate out and rinse with deionized water and let it dry naturally. Finally, densely arranged tower-shaped zinc oxide nanostructures can be obtained on the lower side of the substrate.

Embodiment 3

[0033] A method for hydrothermally decomposing and growing nano-rod type zinc oxide:

[0034] The first step: Add 25% of concentrated ammonia by mass percentage to the concentration of 0.08~0.15M zinc chloride solution and stir it fully to adjust the pH value of the solution between 9~11, and then generate Zn(NH 3 ) 4 2+ In this embodiment, you can choose to add concentrated ammonia water dropwise to the 0.08, 0.10, 0.12 or 0.15M zinc chloride solution, and adjust the pH of the solution to 9, 9.5, 9.7, 10.1 or 11;

[0035] The second step: sealing the above-mentioned solution with ultrasonic treatment for 25 to 35 minutes, in this embodiment, the ultrasonic treatment time is 25, 28, 32 or 35 minutes;

[0036] The third step: insert the cleaned substrate into the solution and seal the solution again, and then place the sealed solution in an environment at 80-98°C for 45-70 minutes. In this embodiment, the sealed solution can be placed at 90°C. Let stand for 45, 51, 62 or 70 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com