LED light source packaging structure for low-temperature coburning ceramic by thermoelectric separating design

A low-temperature co-fired ceramic and LED light source technology, which is applied in the direction of circuits, electrical components, and electrical solid devices, to achieve the effects of simplifying the packaging structure and packaging process, excellent thermal conductivity, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A packaging structure of a single-chip LED light source using an LTCC substrate

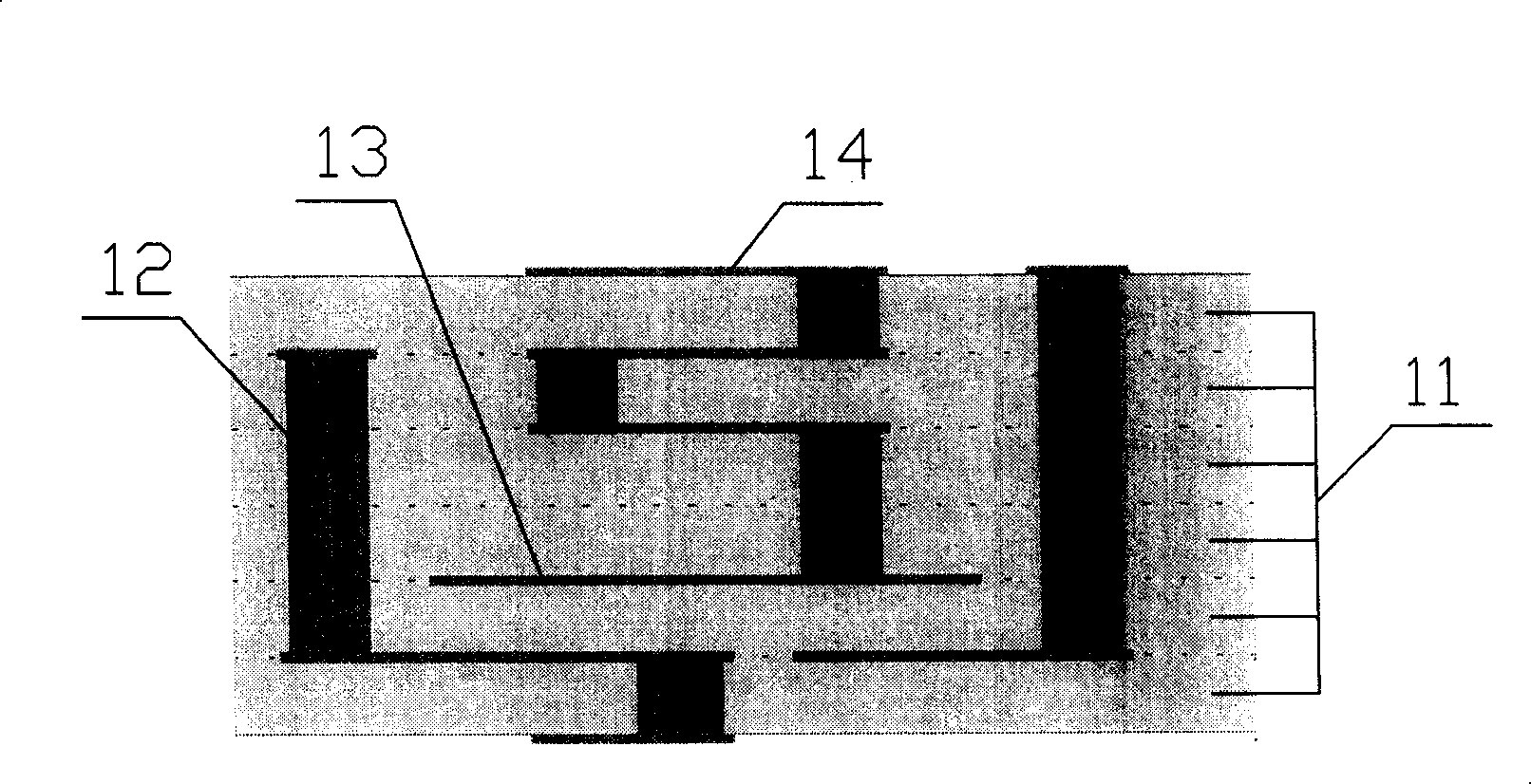

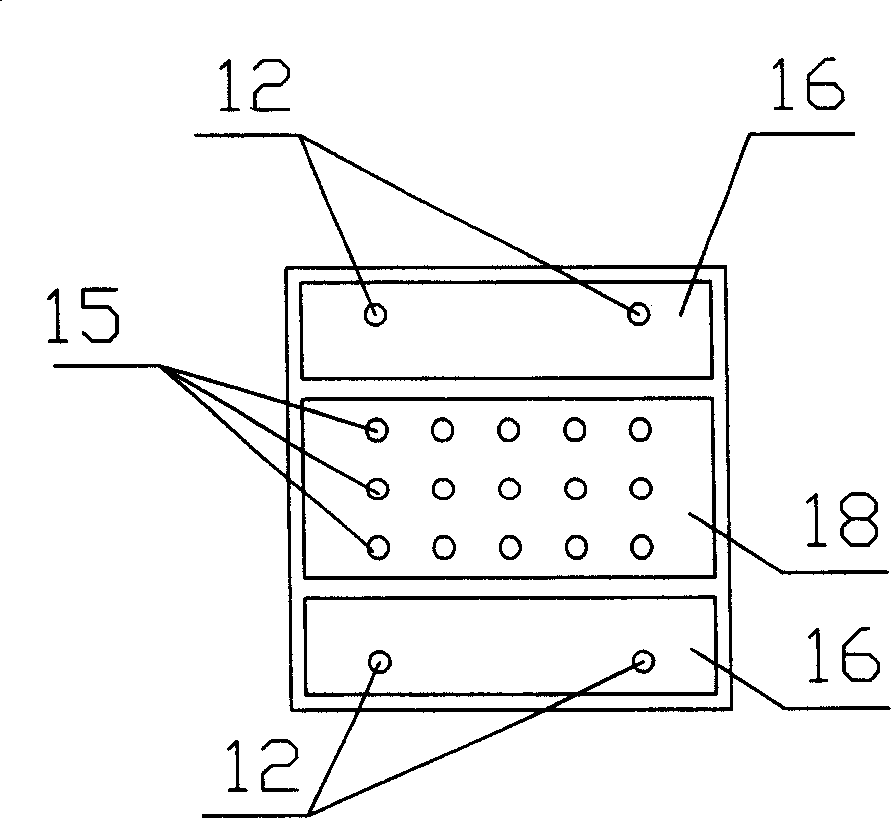

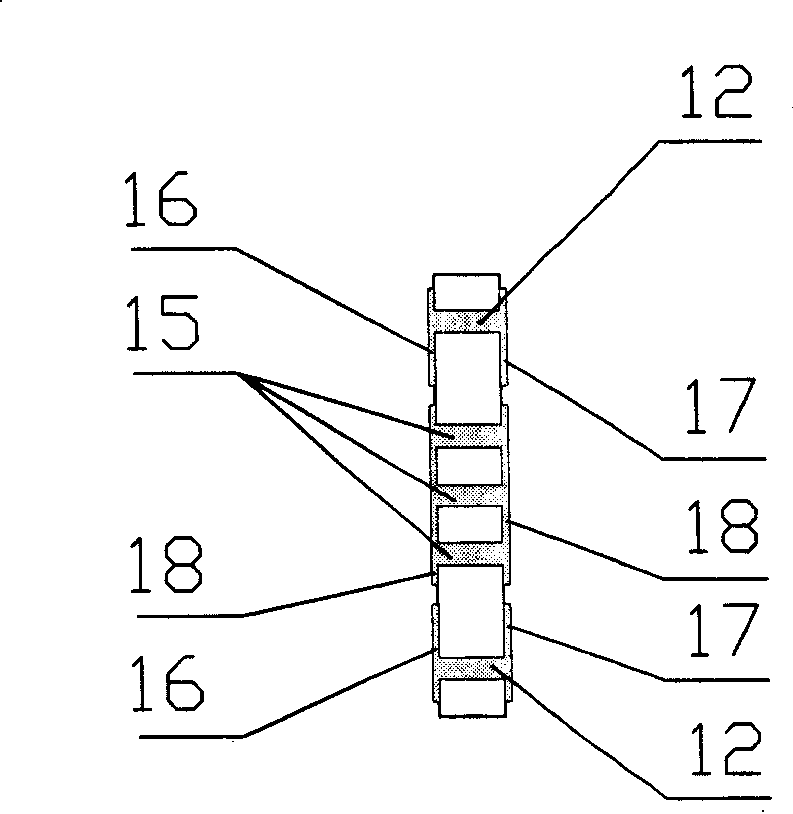

[0040] see Figure 4 , Figure 5 , LTCC substrate 1 is rectangular, and adopts such as figure 2 , 3 The thermoelectric separation structure shown.

[0041] The heat conduction column is filled with silver paste, and the heat generated by the LED chip is transferred to the back of the LED through the silver column.

[0042] Wherein the center of the upper ceramic plate has a cylindrical pit for placing the LED chip 2 .

[0043] The LTCC substrate has produced corresponding circuits and electrodes according to the packaging requirements, and there are 2 electrodes on the back for LED power supply.

[0044] An LED chip 2 is directly fixed on the heat conduction pad in the bottom plane of the substrate pit with high thermal conductivity glue, so that the heat generated by the chip can be quickly transmitted through the LTCC substrate; the power of the LED chip is 1W.

[004...

Embodiment 2

[0047] Embodiment 2 Another packaging structure of a single-chip LED light source using an LTCC substrate

[0048] Basically follow the same steps as in the first embodiment, except that a certain proportion of YAG powder is mixed in the encapsulant 4 , and the YAG powder is excited by a chip that emits light of a specific wavelength to obtain light of a desired color. And glue a lens 5 above the pit of the LTCC substrate, the material of the lens is optical plastic PMMA (acrylic), and it is manufactured by injection molding.

Embodiment 3

[0049] Embodiment 3 A packaging structure of a multi-chip LED light source using an LTCC substrate

[0050] Basically follow the same steps as in Embodiment 1, the difference is that the RGB three-primary color package is used, please refer to Image 6 , that is to use three LED chips, the colors are red, green, and blue, and the working current of the three LED chips is 20mA, and they are fixed together on the plane at the bottom of the same pit on the LTCC substrate; the LTCC substrate has been produced according to the packaging requirements. Corresponding circuits and electrodes enable three LED chips to be independently powered and controlled. There are six electrodes on the back of the LTCC substrate, and each two electrodes independently control a chip.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com