Method for extracting methyl o-phenylendiamine from TDI organic residue and synthesizing TTA using same

A technology of methyl o-phenylenediamine and toluene diisocyanate is applied in the field of chemistry and achieves the effects of less by-products, low production cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

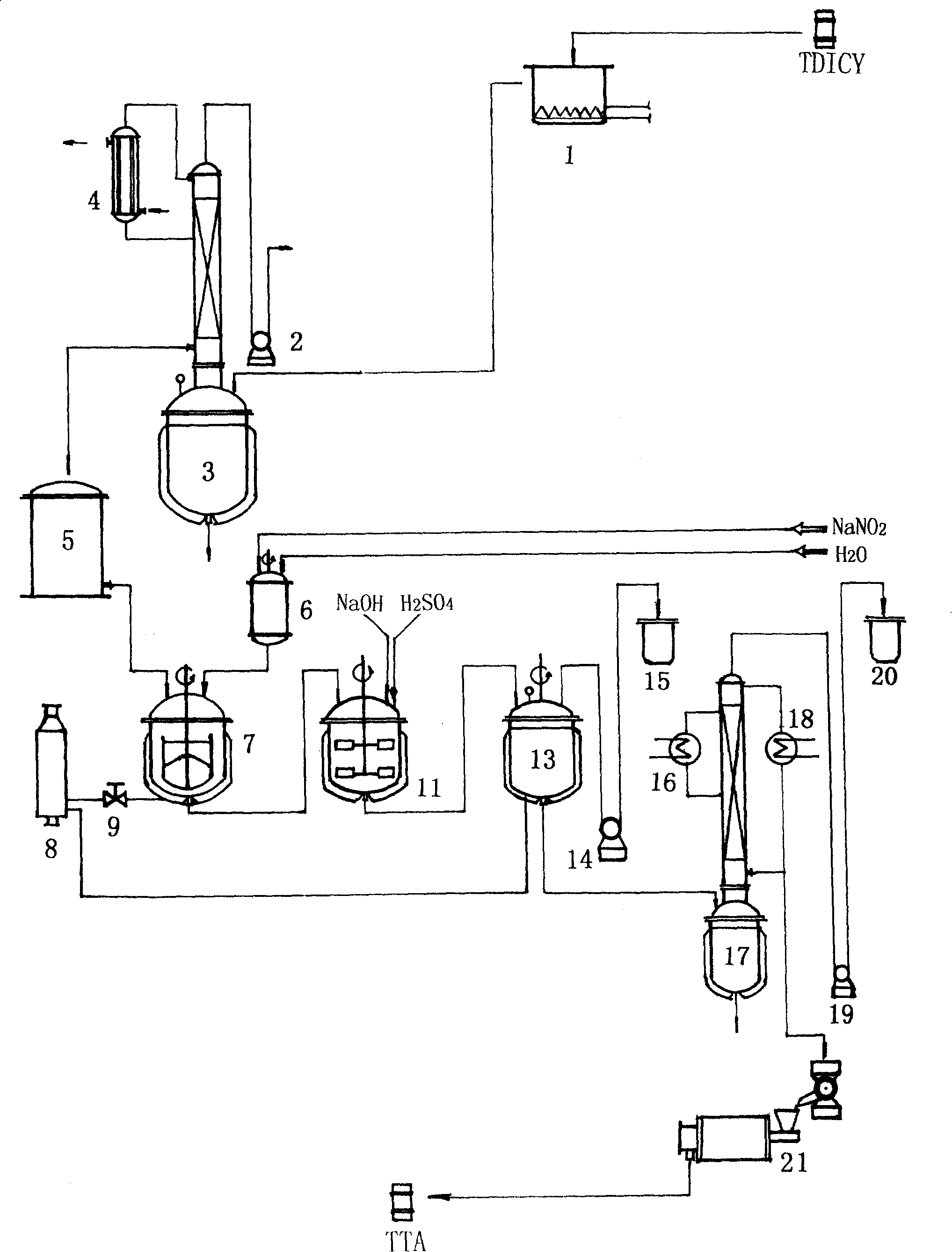

Image

Examples

Embodiment 1

[0024] Take 1700Kg of organic residue with OTD content of 90% in TDI hydrogenation organic residue as an example, and the organic residue is stored in a 200Kg iron drum. The specific extraction process is as follows:

[0025] a. Dissolution process: put 1700Kg TDI organic residue into the chemical material tank 1 first, open the steam heating valve to pass the heat source to the chemical material tank 1, control the water temperature of the chemical material at 85-90°C for 9 hours, after the organic residue is completely dissolved , into the purification distillation still;

[0026] b. Purification and refining process: under the process conditions of controlling the temperature of the organic residue in the purification and rectification kettle 3 to 172°C and a vacuum degree of 200Pa, the ratio of receiving and reflux is controlled to be 6.0:4.5, and the content of the received methyl o-phenylenediamine is more than 99.2%. , a total of 1516Kg of methyl-o-phenylenediamine pro...

Embodiment 2

[0028] Taking 2520Kg of organic residue with an OTD content of 97% in TDI hydrogenation residue as an example, the specific extraction process is as follows:

[0029] a. Dissolving process: put 2520Kg TDI organic residue into chemical material tank 1 first, open the steam heating valve to pass heat source to chemical material tank 1, control the water temperature of chemical material at 90°C for 7.5 hours, after the organic residue is completely dissolved, sent to the purification and rectification process;

[0030] b. Purification and refining process: under the process conditions of the temperature of the organic residue in the purification and rectification kettle 3 of 175° C. and a vacuum degree of 180 Pa, the receiving and reflux ratio is controlled to 7.2: 3.8, and the content of the received methyl o-phenylenediamine is more than 99.4%. A total of 2430Kg of methyl-o-phenylenediamine product with a content of 99.43% was extracted, and the recovery rate was 99.41%. It too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com