Method for preparing dibasic alcohol

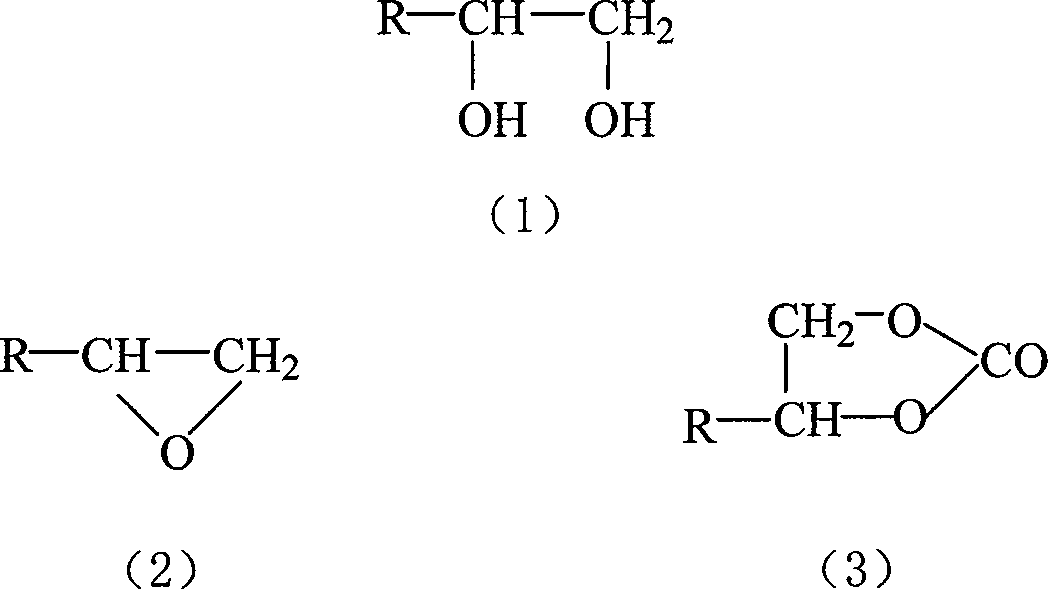

A technology of dihydric alcohol and polyethylene glycol, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of oxygen-containing compounds, etc., can solve the problems of increased production costs, reduce production costs, avoid hydrolysis catalyst recovery and The effect of attrition problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

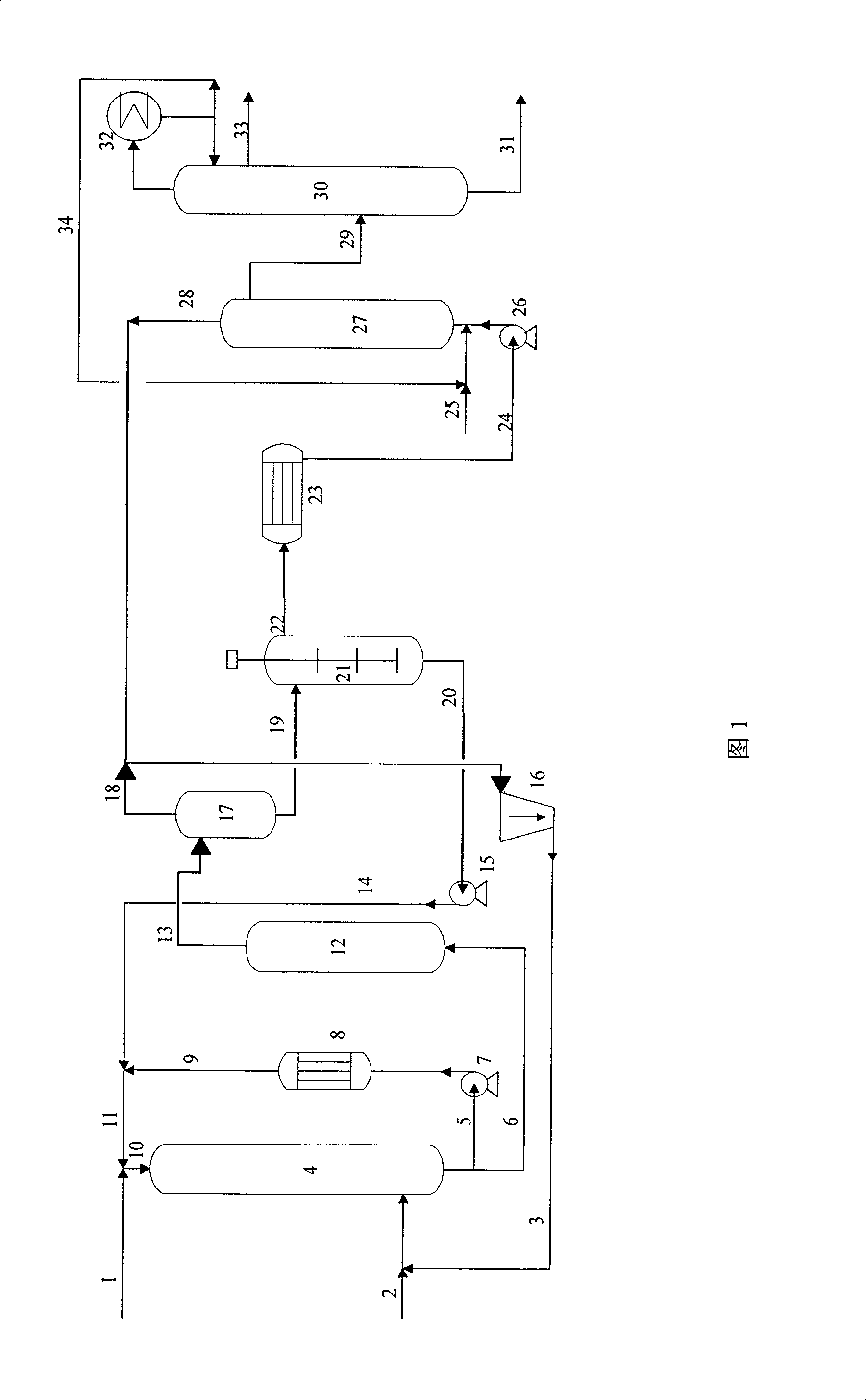

Method used

Image

Examples

Embodiment 1

[0038] CO control 2 The mol ratio of / propylene oxide is 1.1, enters synthesis reactor, the amount of catalyzer tetraethylamine bromide is 1.0% of propylene oxide weight, 180 ℃ of reaction temperatures, 1 hour reaction time, the purity 99.5% of propylene carbonate, Yield 99.5% (calculated as propylene oxide)

[0039] Adjust the molar ratio of water / propylene carbonate to 2, enter the hydrolysis reactor, the pressure is 0.3MPa, the reaction temperature is maintained at 80°C, and the reaction is 0.5 hour, the conversion rate of propylene carbonate is 99.5%, and the selectivity of propylene glycol is 100%.

[0040] The rectification tower is a packed tower with 20 theoretical plates, a reflux ratio of 3.0, a tower inner pressure of 0.018Mpa, a tower bottom temperature of 160°C, a purity of propylene glycol above 99.5%, and a rectification yield of 97%. The total yield of propylene glycol is 96.0% (calculated as propylene oxide).

Embodiment 2

[0042] CO control 2 The molar ratio of / ethylene oxide is 1.05, enters synthesis reactor, the amount of catalyst KI / PEG is 1.0% of propylene oxide weight, 150 ℃ of reaction temperatures, 1 hour reaction time, the purity 99.5% of ethylene carbonate, yield Rate 99.5% (based on propylene oxide)

[0043] Adjust the molar ratio of water / ethylene carbonate to 1.5, enter the hydrolysis reactor, the pressure is 7.0MPa, the reaction temperature is maintained at 240 ° C, and the reaction is 4.0 hours. The conversion of ethylene carbonate is 100%, and the selectivity of ethylene glycol is 100%.

[0044] The rectification tower is a tray tower with 30 theoretical plates, reflux ratio of 2.5, tower inner pressure of 0.018Mpa, tower bottom temperature of 165°C, ethylene glycol purity of over 99.5%, and rectification yield of 98%. The total yield of ethylene glycol is 97.5% (calculated as ethylene oxide).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com