Aluminum alloy and its composite material non-vacuum semi-solid state vibration-rheological connection method

A composite material and connection method technology, applied in welding equipment, welding equipment, non-electric welding equipment and other directions, can solve the problems of unavoidable interface reaction, difficult brazing process, over-ablation and erosion of base metal, etc., to overcome adverse consequences, Ideal engineering significance, low soldering temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following examples describe the present invention in more detail:

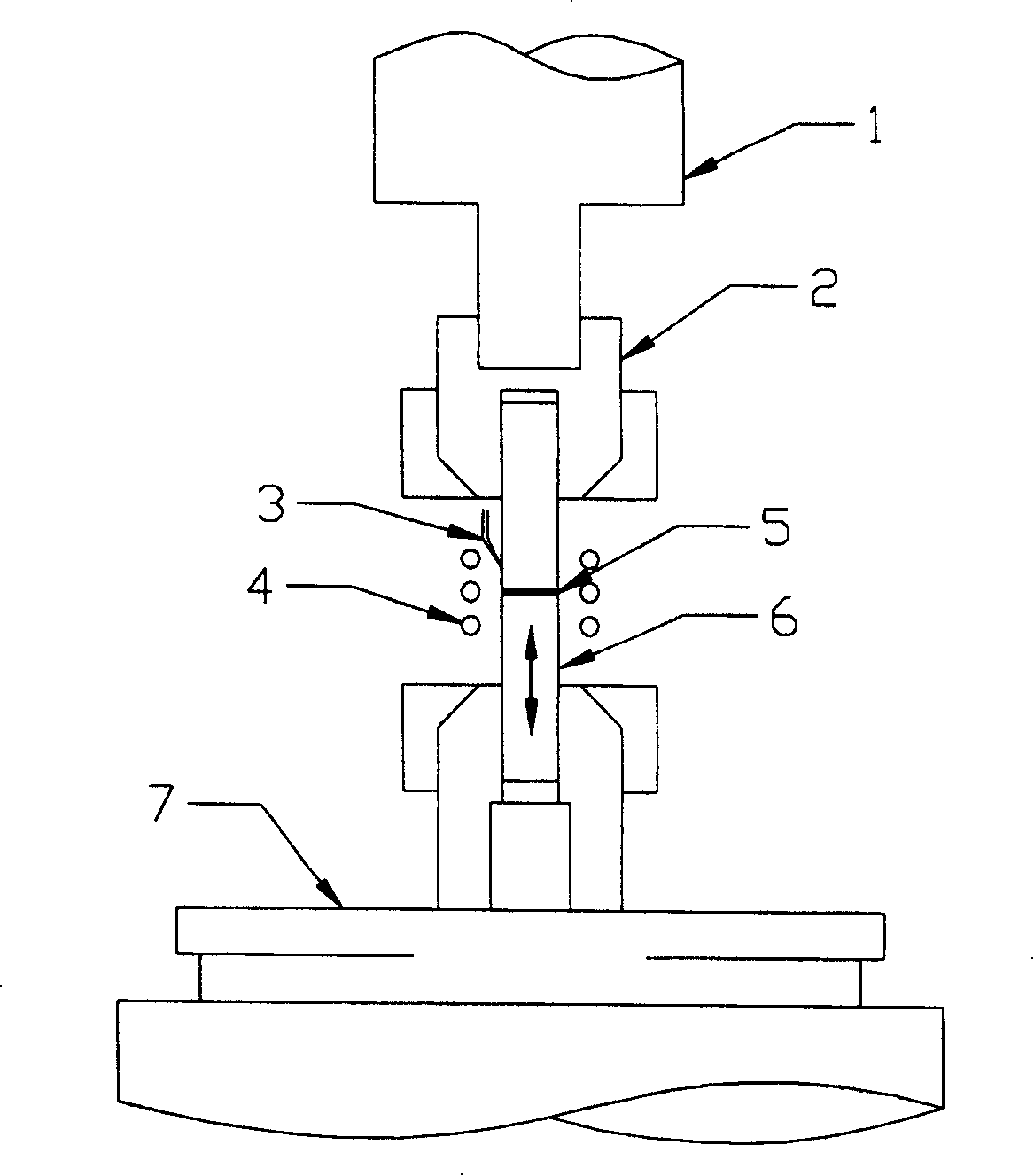

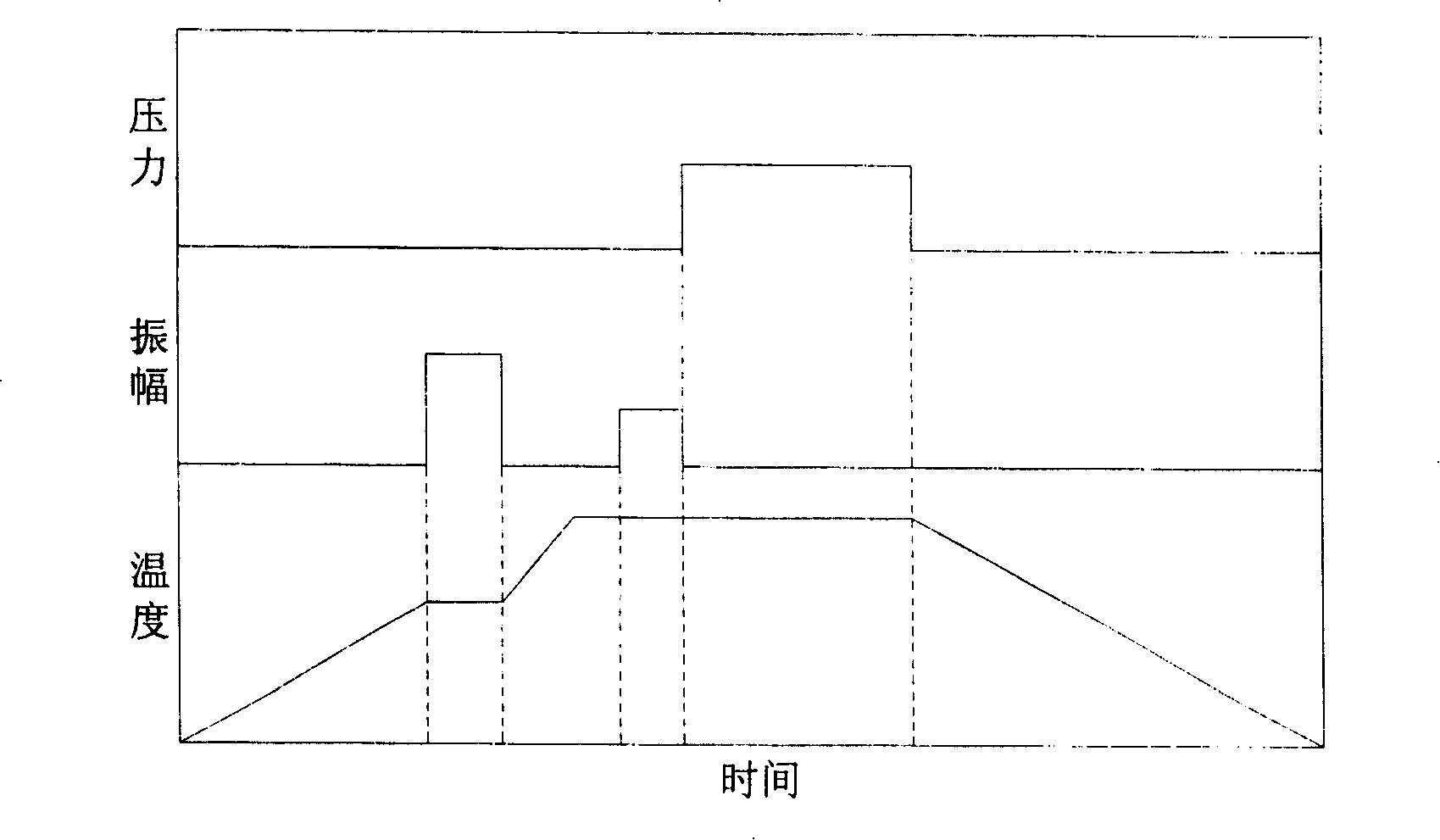

[0049] combine figure 1 1. Install the aluminum-based composite material weldment 6 on the fixture 2 and place medium-temperature solder 5 such as Zn-Al on the two surfaces to be welded. The solder can be sheet-like, foil-shaped, coated or sprayed on the surface to be welded in advance. Heating the weldment through the high-frequency induction coil 4, the heating temperature is between 380-400°C, the heating temperature is controlled by the thermal couple 3, the middle layer solder is melted by heating, the vibration device 7 is started, the amplitude is 0.1-1.5mm, during the vibration process The medium temperature is constant, and the vibration time is 10-300 seconds. After the vibration stops, the temperature rises according to a certain heating rate, and is kept at a predetermined temperature to make the brazing filler metal dissolve a certain thickness of the base metal. The holding temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com