Method for synthesizing isotropic silicon nitride powder adopting layer type material-distribution

A technology of combustion synthesis and silicon nitride powder, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of high production efficiency and low impurity content, achieve consistent phase content, high purity, and increase nitrogen penetration. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

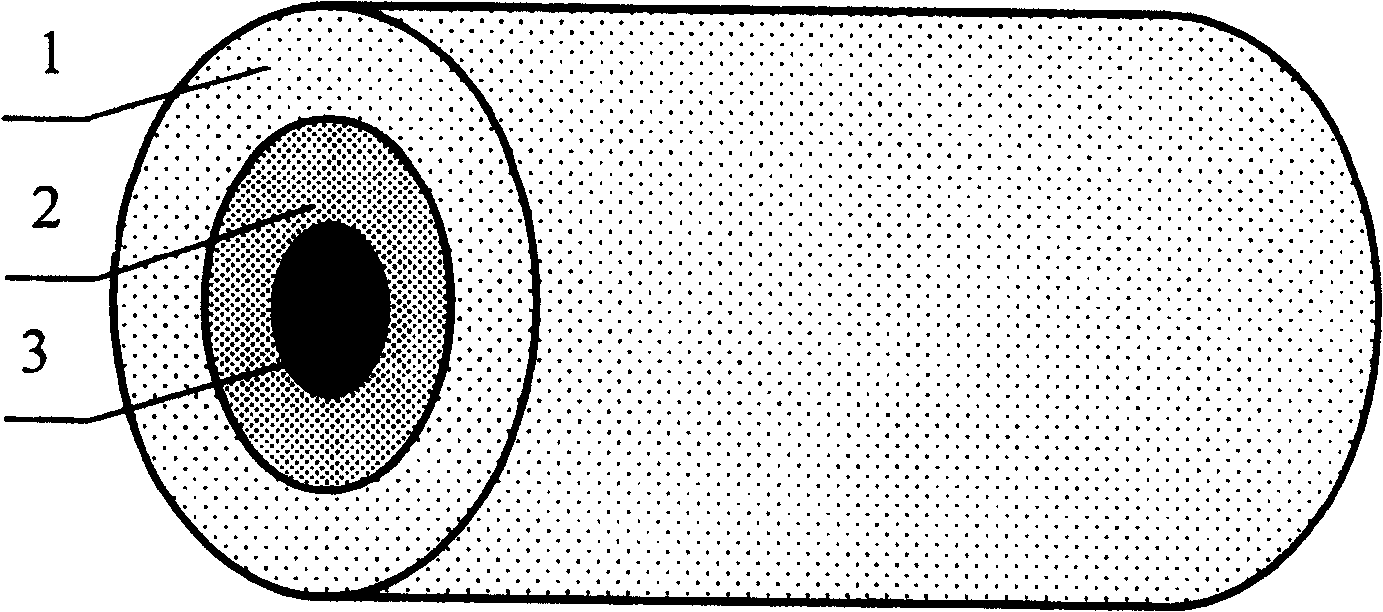

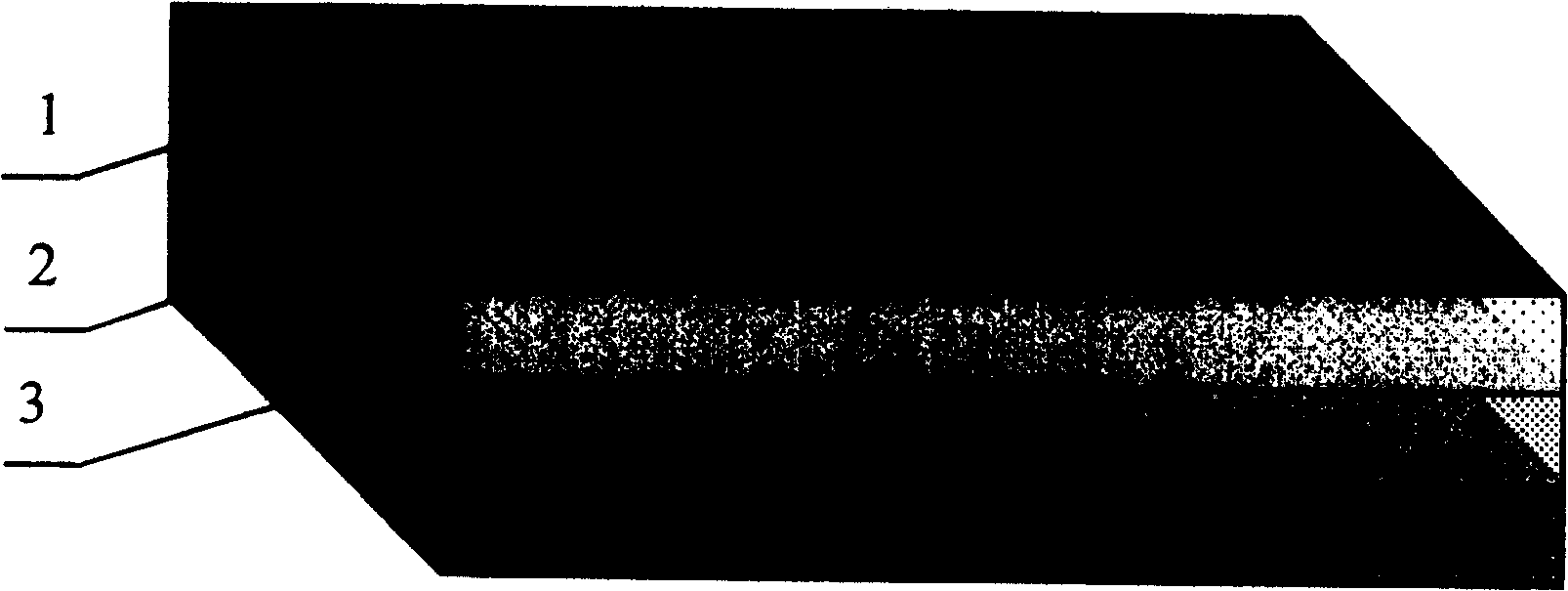

Embodiment 1

[0053] Silicon powder with an average particle size of 25μm (purity greater than 98.5%) and silicon nitride powder with an average particle size of 2.2μm (purity greater than 96%, alpha phase content about 93%), respectively, according to different weight ratios (in this example It is three kinds of ingredient ratios) after the ingredients are mixed in the ball milling tank of the roller ball mill for 72 hours, three parts of the reaction mixture with different composition ratios are obtained, namely the reaction mixture A (the ingredient ratio is Si:Si 3 N 4 =45:55), reaction mixture B (the ratio of ingredients is Si:Si 3 N 4 =47.5:52.5) and the reaction mixture C (the batching ratio is Si:Si 3 N 4 =50:50), the total weight of the reaction mixtures A, B, and C is 4.8 kg. The reaction mixtures A, B, and C were put into an electric heating oven and dried at 70°C. Then put the three reaction mixtures with different component ratios in a cylindrical porous graphite crucible accordi...

Embodiment 2

[0056]The raw materials used in this embodiment are silicon powder with an average particle size of 17 μm (purity greater than 98.5%) and silicon nitride powder with an average particle size of 1.5 μm (purity greater than 98%, alpha phase content about 95%). Respectively carry out ingredients according to different weight ratios and grind and mix to obtain three reaction mixtures with different composition ratios, namely reaction mixture A (the ingredient ratio is Si:Si 3 N 4 =45:55), reaction mixture B (the batching ratio is Si:Si 3 N 4 =50:50) and reaction mixture C (the batching ratio is Si:Si 3 N 4 =55:45), the total weight of the reaction mixtures A, B, and C is 1.2 kg. The above-mentioned grinding and mixing of the three reaction mixtures is carried out in the following manner: first, the silicon powder is milled and mixed in the ball mill barrel of the agitated ball mill with absolute ethanol as the ball milling medium for 10 hours, and then the inert diluent silicon nitrid...

Embodiment 3

[0058] The raw materials used in this embodiment are silicon powder with an average particle size of 5 μm (purity greater than 98.5%) and silicon nitride powder with an average particle size of 3 μm (purity greater than 96%, alpha phase content about 90%). Respectively carry out ingredients according to different weight ratios and grind and mix to obtain three reaction mixtures with different composition ratios, namely reaction mixture A (the ingredient ratio is Si:Si 3 N 4 =42.5:57.5), reaction mixture B (the ratio of ingredients is Si:Si 3 N 4 =47.5:52.5) and reaction mixture C (the batching ratio is Si:Si 3 N 4 =52.5:47.5), the total weight of the reaction mixtures A, B, and C is 5 kg. The above-mentioned grinding and mixing of the three reaction mixtures is carried out in the following manner: firstly, the silicon powder is milled and mixed in the ball mill barrel of the agitated ball mill using absolute ethanol as the ball milling medium for 6 hours, and then dried in a vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com