A method for preparing silicon-aluminum nitride or nitrogen oxide phosphor

A technology of nitrogen oxides and nitrides, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as operability, low stability and repeatability, complex control factors such as solubility ratio, complex chemical reaction process, etc. , to achieve the effect of ensuring uniformity and stability, good crystallization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing silicon-aluminum nitride or oxynitride fluorescent powder, the steps of the method are as follows:

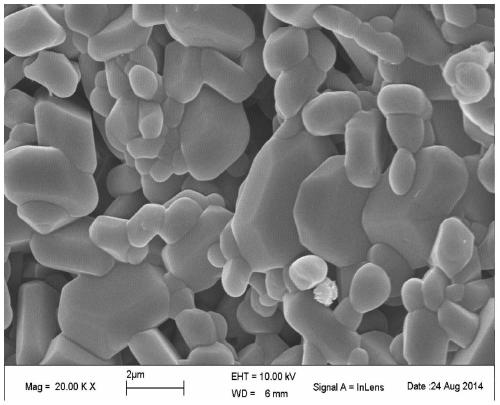

[0045] (1) According to the general chemical formula: Ca Si Al ON: xEu, where the value of m is 3.5, the value of n is 0.5, and x=0.08, the raw materials are weighed. The raw material powder is Si powder, particle size D50=5um; a-Si N powder, particle size D=1um; Al powder, particle size D=5um; AlN powder, particle size D=1um; CaO powder, particle size D=5um; Ca N powder , particle size D=5um; Eu O powder, particle size D=1um; wherein the mass ratio of Si powder to a-SiN powder is 0.65, and the mass ratio of Al powder to AlN powder is 2.6;

[0046] (2) PVB binder weighing 1% of raw material powder gross mass;

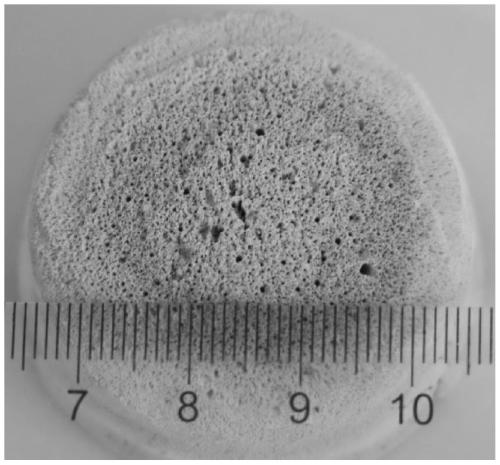

[0047] (3) Add raw material powder and binder into tert-butanol solvent, the volume ratio of raw material powder and tert-butanol is 15:85, use planetary ball mill and nitrogen protection ball mill for 2 hours, and obtain mixed uniform slur...

Embodiment 2

[0051] A method for preparing silicon-aluminum nitride or oxynitride fluorescent powder, the steps of the method are as follows:

[0052] (1) According to the general chemical formula: Si Al ON: xEu, where Z is 0.5 and x is 0.03, weigh the raw materials; the raw material powder is Si powder, particle size D=5um; a-Si N powder, particle size D=1um; AlO powder, particle size D=5um; AlN powder, particle size D=1um; EuO powder, particle size D=1um; wherein the mass ratio of Si powder to a-Si N powder is 2.3;

[0053] (2) PVB binder weighing 0.2% of raw material powder gross mass;

[0054] (3) Add the raw material powder and binder into the tert-butanol solvent, the volume ratio of the raw material powder and tert-butanol is 3:7, use a planetary ball mill to mill for 8 hours under the protection of nitrogen, and obtain a mixed homogeneous slurry material;

[0055] (4) Pour the obtained slurry into a mold and freeze and solidify it in an ethanol low-temperature bath at -60°C for 2...

Embodiment 3

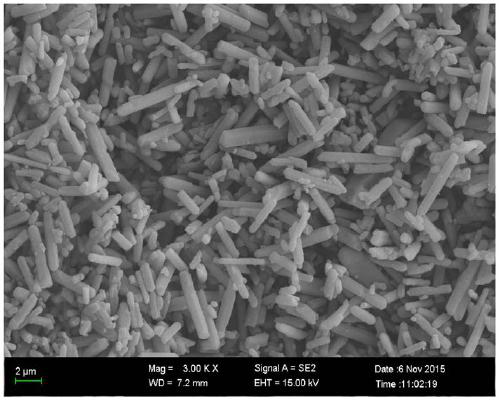

[0058] A method for preparing silicon-aluminum nitride or oxynitride fluorescent powder, the steps of the method are as follows:

[0059] (1) According to the general chemical formula: Al Si Eu N, where y is 0.03 and x is 0.003, the raw material is weighed; the raw material powder is Al powder, particle size D=5um; AlN powder, particle size D=1um; Si powder, Particle size D=5um; EuO powder, particle size D=1um; wherein the mass ratio of Al powder to AlN powder is 3:2;

[0060] (2) PVB binding agent weighing 0.5% of raw material powder gross mass;

[0061] (3) Add raw material powder and binder into tert-butanol solvent, the volume ratio of raw material powder and tert-butanol is 1:4, use planetary ball mill to mill for 8 hours under the protection of nitrogen, and obtain mixed homogeneous slurry material;

[0062] (4) Pour the obtained slurry into a mold and freeze and solidify it in an ethanol low-temperature bath at -40°C for 2 hours; place the solidified green body in a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com