Composite filtering-regeneration device for particulates in exhaust gas from diesel vehicle

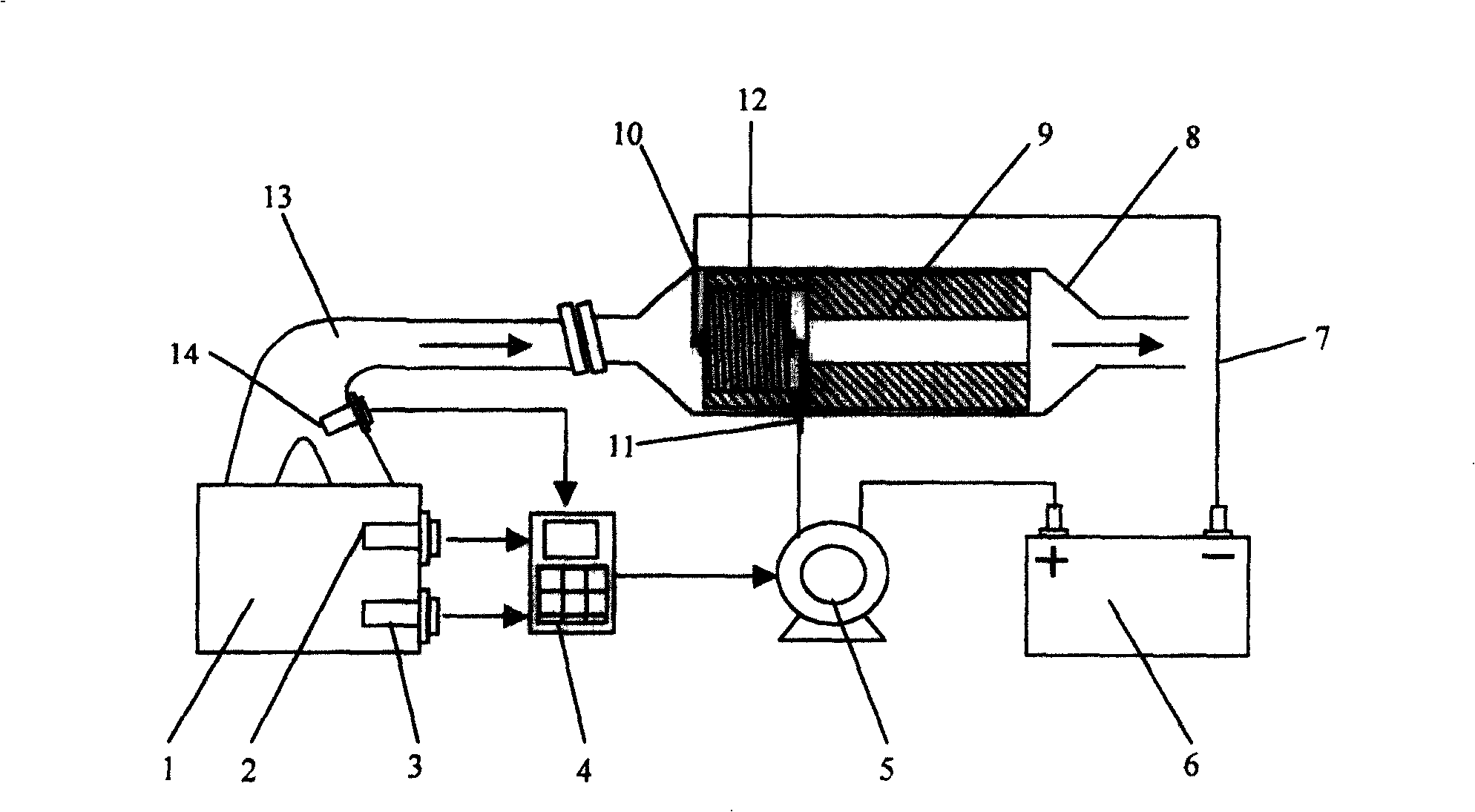

A technology of composite structure and regeneration device, which is applied to exhaust devices, mufflers, engine components, etc., can solve problems such as explosion and particle filter melting, and achieve the effects of long service life, simple structure and uniform temperature distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

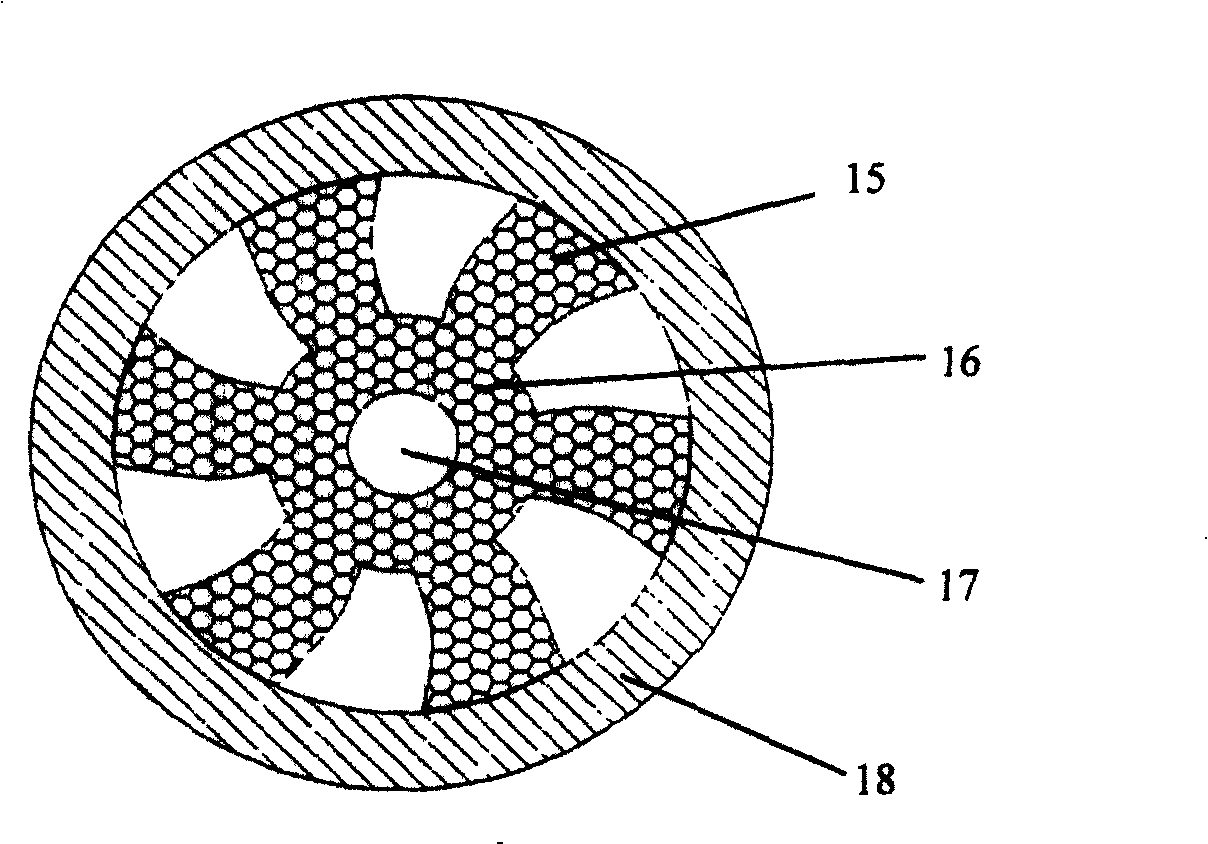

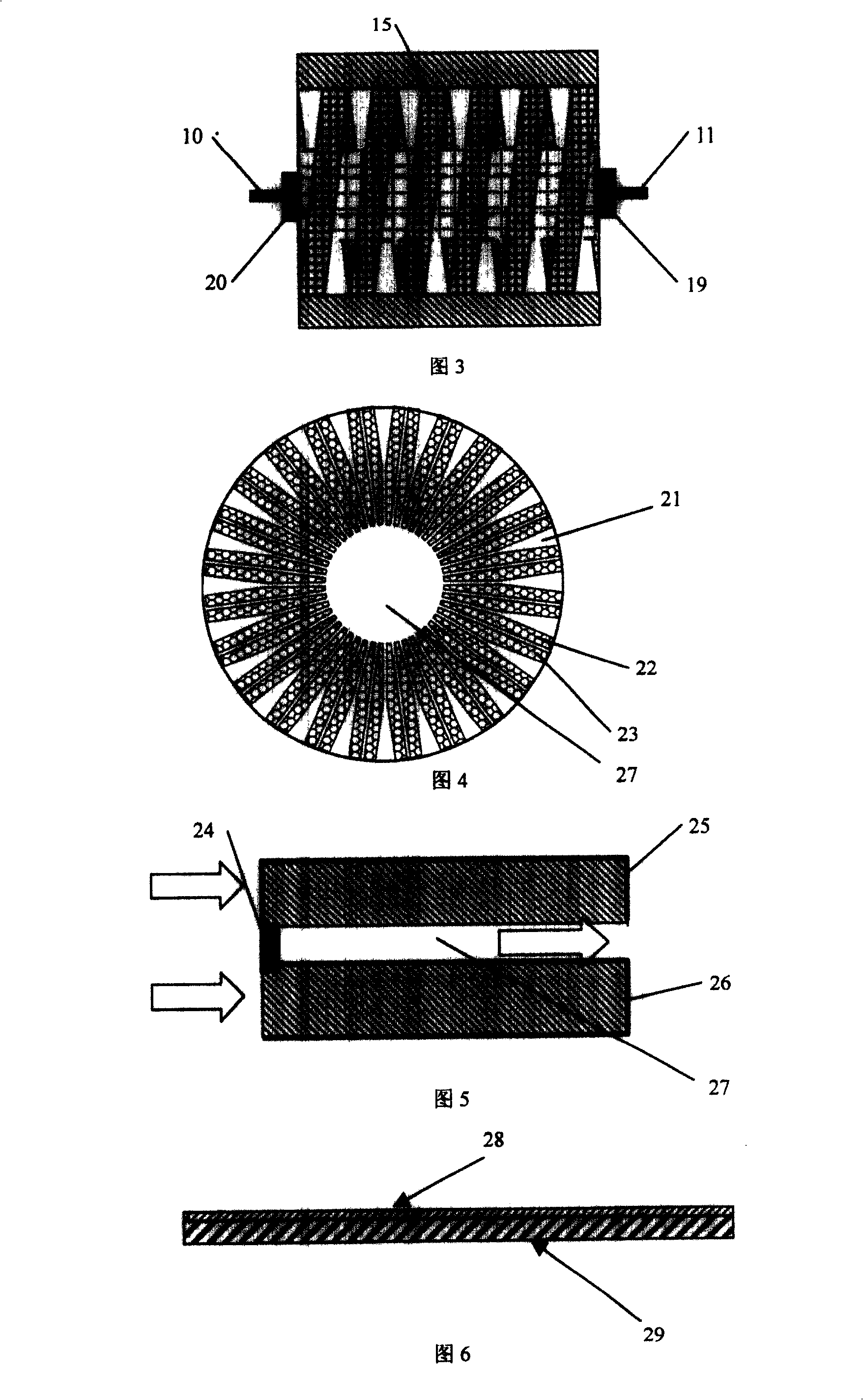

[0049] ①The silicon carbide foam ceramic with a volume fraction of 30% and an average foam diameter of 1mm is machined into a spiral structure with six spiral blades. , the center hole φ10mm.

[0050] ②Machining tubular silicon carbide foam ceramics, with an outer diameter of φ180mm and an inner diameter of φ140mm.

[0051] ③ The tubular silicon carbide foam ceramics obtained in ② are sleeved on the periphery of the spiral structure obtained in ①, and the two are firmly bonded with ethyl silicate to obtain a spiral turbulent particulate filter. The external dimension is φ180mm×100mm.

[0052] ④Take two silicon carbide ceramic electrodes φ20mm×15mm, and solder them on both ends of the φ180mm×100mm spiral turbulent particle filter described in ③ by brazing, as the base of the metal electrode; A stainless steel column with a diameter of 6mm is brazed on each seat as an electrode connected to the wire; a spiral turbulent particle filter with an electric heating regeneration func...

Embodiment 2

[0057] The difference from Example 1 is that:

[0058] Before the test, the electric heating spiral turbulent particulate filter was installed in the designated position of the exhaust passage of the diesel engine, and the engine speed was 2160rpm, the torque was 188Nm, and the power was 42.5kW to run for 5 hours, so that the electric heating spiral turbulent particulate filter was operated for 5 hours. The filter fully accumulates soot, and then turns on the electric heating circuit for electric heating regeneration. After regeneration, the same 13 working condition test as in Example 1 was carried out.

Embodiment 3

[0060] The difference from Example 1 is that:

[0061] The volume fraction of silicon carbide foam ceramics composing the electrically heated spiral turbulent particulate filter and the wall-flow particulate filter is 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com