Aluminum electrolytic capacitor

A technology for aluminum electrolytic capacitors and capacitors, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of increased leakage current, corrosion of anode aluminum wires, corrosion and disconnection of anode aluminum wires, etc., to achieve impedance performance and low-temperature characteristics. Excellent, high reliability, low risk of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described below.

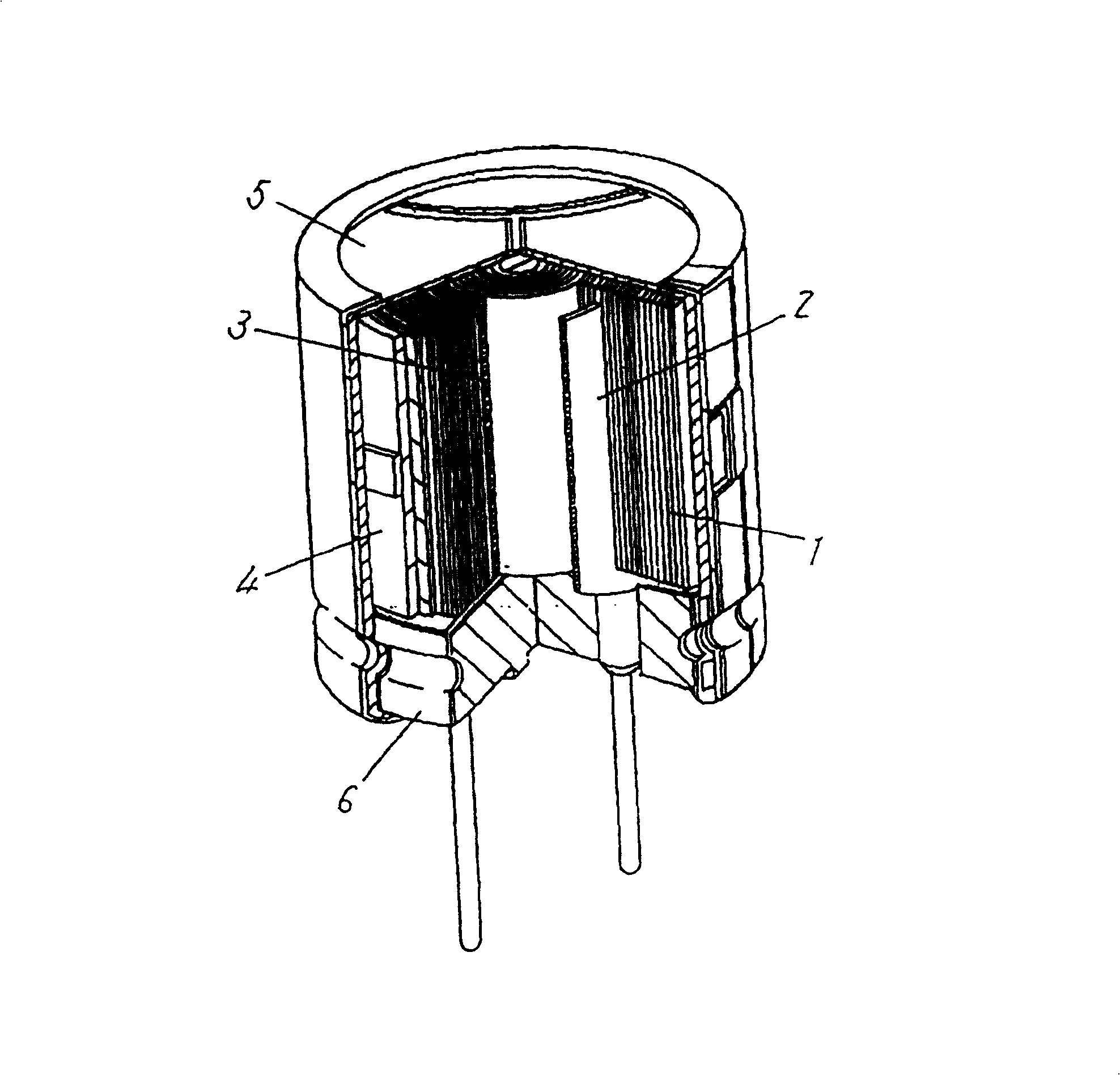

[0024] The electrolytic capacitor of the present invention has an anode aluminum foil, a cathode aluminum foil on which a dielectric layer made of aluminum oxide is formed, and a separator which is inserted between the anode aluminum foil and the cathode aluminum foil and wrapped in this state To form a capacitor element, it is impregnated with an electrolytic solution, then packed into an aluminum case, and finally the opening of the aluminum case is sealed with a sealing material.

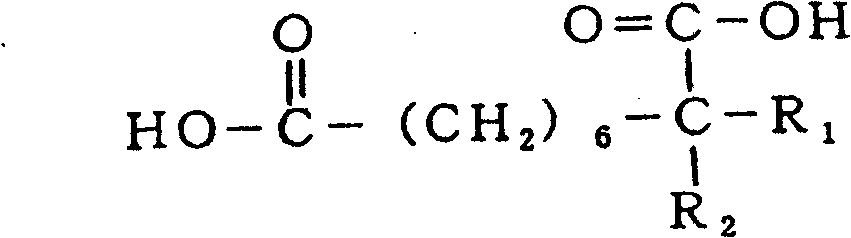

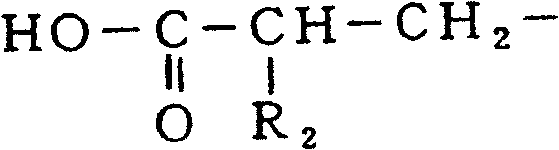

[0025] According to the present invention, the water content of the electrolytic solution is 20 to 90% by weight. The electrolyte contains ammonium formate, ammonium acetate, ammonium lactate, ammonium glycolate, ammonium oxalate, ammonium succinate, ammonium malonate, ammonium adipate, ammonium benzoate, ammonium glutarate, ammonium azelate One or more compounds are used as the "main electrolyte" and also contain more than 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com